Method for selectively electro-adsorbing halogen ions in composite salt wastewater

A halogen ion and electro-adsorption technology, which is applied in separation methods, chemical instruments and methods, water pollutants, etc., can solve the problems of weak binding and trapping of halogen ions, weak affinity, difficulty in adapting to the requirements of composite wastewater, etc., and achieve excellent Effects of regeneration stability, increased adsorption capacity, and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Step 1: Active material preparation:

[0076] (1) Put 40mg of graphite oxide powder into 50ml of ethylene glycol at 15°C for 1h30min to obtain solution 1;

[0077] ⑵The 1gBi(NO 3 ) 3 ·5H 2 O, 1gNaOH, 500mg polyvinylpyrrolidone were put into 50ml ethylene glycol and stirred at 25°C to obtain solution 2;

[0078] (3) Mix solution 1 and solution 2, stir at 25°C for 30 minutes, and 2 Under the atmosphere, heat the mixed solution with an oil bath at 110°C for 1 hour, and quickly add 10 g of ascorbic acid 5 minutes after the start of the reaction;

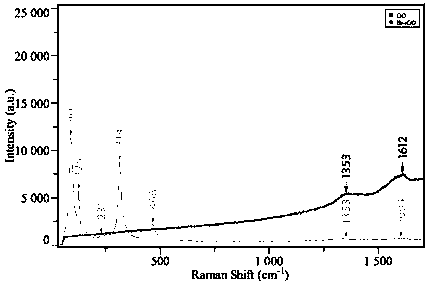

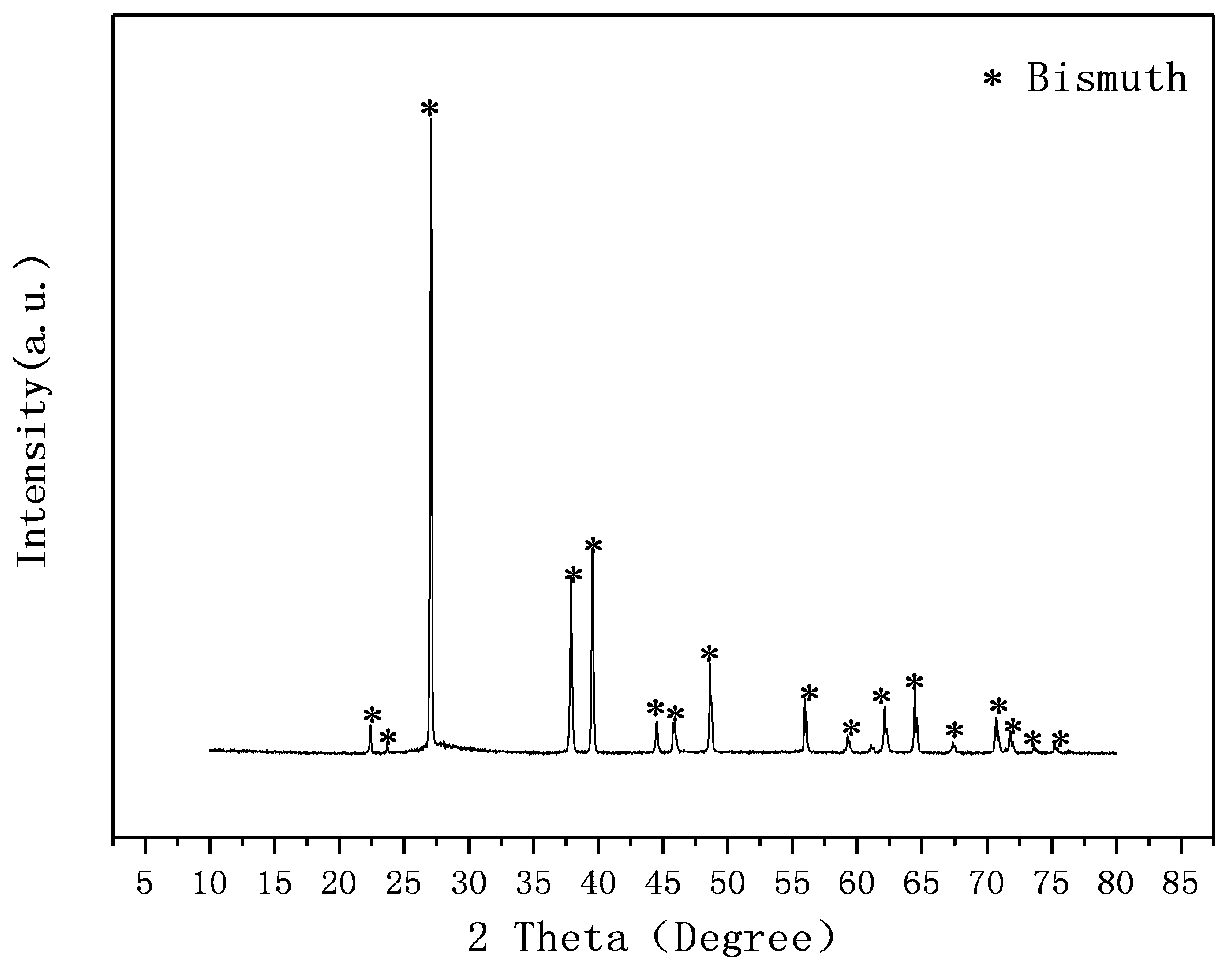

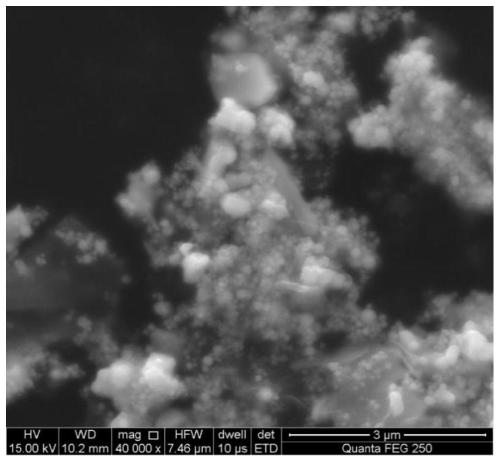

[0079] (4) The precipitate was obtained by centrifugation, washed three times with distilled water and alcohol, dried in a constant temperature drying oven at 60°C for 12 hours, and the product was ground to obtain the C@Bi / rGO composite material, in which bismuth accounted for 83.5%. See XRD diagram figure 1 , SEM image see figure 2 , TEM image see image 3 , see Ramantu Figure 4 , XPS figure see Figure 5 , thermogr...

Embodiment 2

[0089] The electrode obtained in step 2 of Example 1 is used as the anode, and the activated carbon material is used as the cathode to form an asymmetric desalination system, and the composite salt solution is used as the electrolyte, wherein the anion concentration ratio F - : Cl - : NO 3 - : SO 4 2- =5:9:14:22, the voltage during the cycle is 1.2V, after 10 cycles, the ratio of removal rate F - : Cl - : NO 3 - : SO 4 2- =18.9:72.5:2.3:6.3, among which the removal rate of chloride ion is the highest, followed by fluoride ion, and then sulfate ion. For specific results, see Figure 13 , Figure 11 is the voltage-current variation curve during the adsorption process, which is obtained through the electrochemical workstation test, Figure 12 It is the result obtained by online monitoring of the conductivity of the solution through a conductivity meter. Its change trend is the same as that of the current change, and its periodic change reflects the good reversible cycl...

Embodiment 3

[0091] (1) Put 60mg of graphite oxide powder into 50ml of ethylene glycol at 15°C for 1h30min to obtain solution 1;

[0092] (2) Put 1gBi(NO3)3·5H2O, 2gNaOH, and 1g polyvinylpyrrolidone into 50ml ethylene glycol and stir at 25°C to obtain solution 2;

[0093] (3) Mix solution 1 and solution 2, stir at 25°C for 30 minutes, and 2 Under the atmosphere, the mixed solution was heated and reacted with an oil bath at 120°C for 1 hour, and 12 g of ascorbic acid was quickly added 5 minutes after the reaction started;

[0094] (4) The precipitate was obtained by centrifugation, washed three times with distilled water and alcohol, dried in a constant temperature drying oven at 60°C for 12 hours, and the product was ground to obtain a C@Bi / rGO composite material similar in appearance to the example. Among them, bismuth accounts for 96.2%.

[0095] The anode was prepared according to Step 2 of Example 1 and the adsorption performance was tested according to Step 3.

[0096] The removal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com