High-precision pneumatic chuck structure

A pneumatic chuck, high-precision technology, applied in the direction of the chuck, etc., can solve the problems of reducing the rotation accuracy of the workpiece end, the traditional contact bearing is difficult to achieve the machining accuracy, reducing the rotation accuracy of the chuck, etc., to avoid direct contact, reduce The effect of small friction and improved rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings.

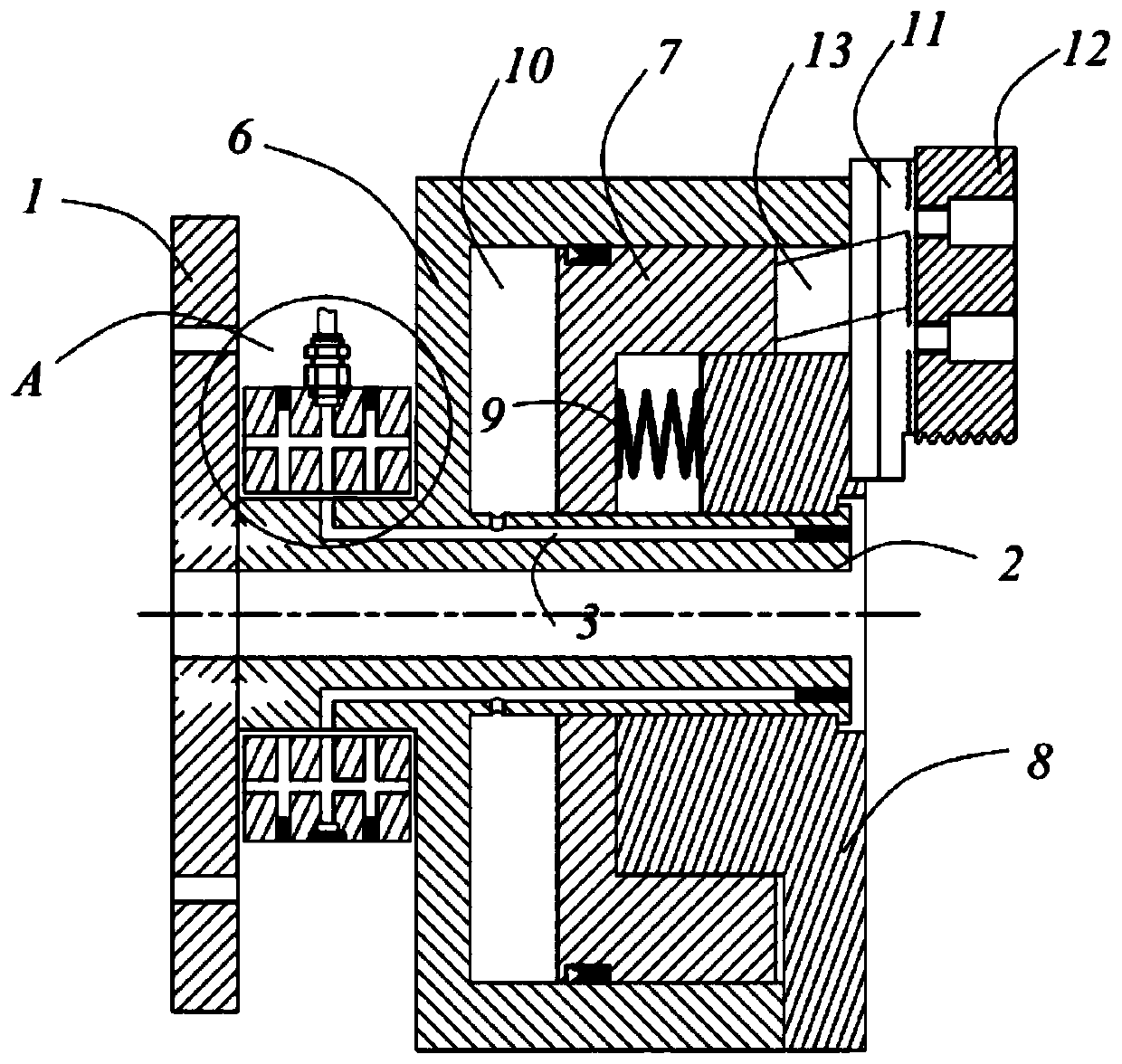

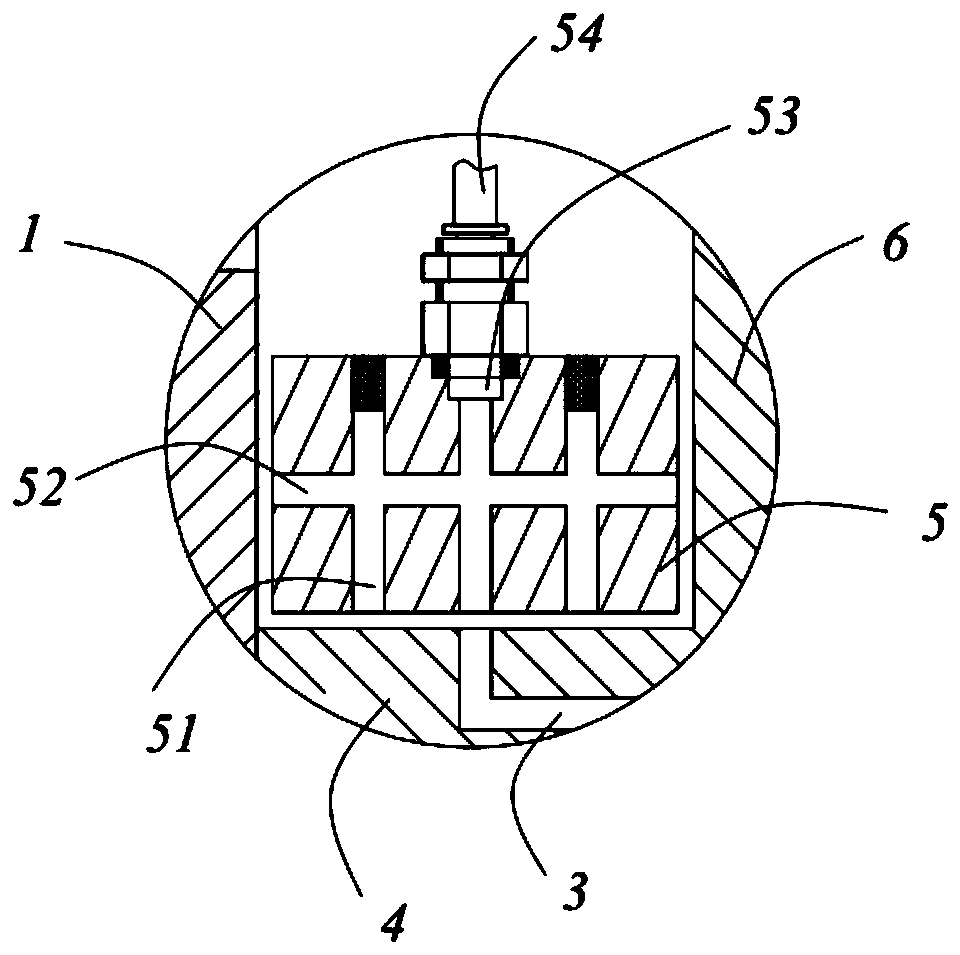

[0019] like figure 1 A high-precision pneumatic chuck structure is shown, which is installed on the flange 1 of the machine tool, and includes a rotating shaft 2 fixedly connected with the flange 1, a pneumatic assembly arranged in the front of the rotating shaft 2, and a clamp disposed on the pneumatic assembly. The disc assembly and the ventilation bearing arranged at the rear of the rotating shaft 2, the ventilation bearing adopts aerostatic bearing, and a ventilation groove 3 is arranged in the rotating shaft 2, and the ventilation groove 3 communicates the pneumatic assembly and the aerostatic bearing. ; A part of the air introduced into the aerostatic bearing forms an air film in the aerostatic bearing, and the other part enters the pneumatic assembly through the ventilation groove 3 to realize the drive of the chuck assembly; The adjustment of the chuck assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com