Cover plate mold for cancelling phosphating process

A cover plate and mold technology, which is applied in the field of clutch cover surface treatment and processing, can solve problems such as harsh production environment, high labor intensity, and low production efficiency, and achieve the effects of saving procedures, reducing processing procedures, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

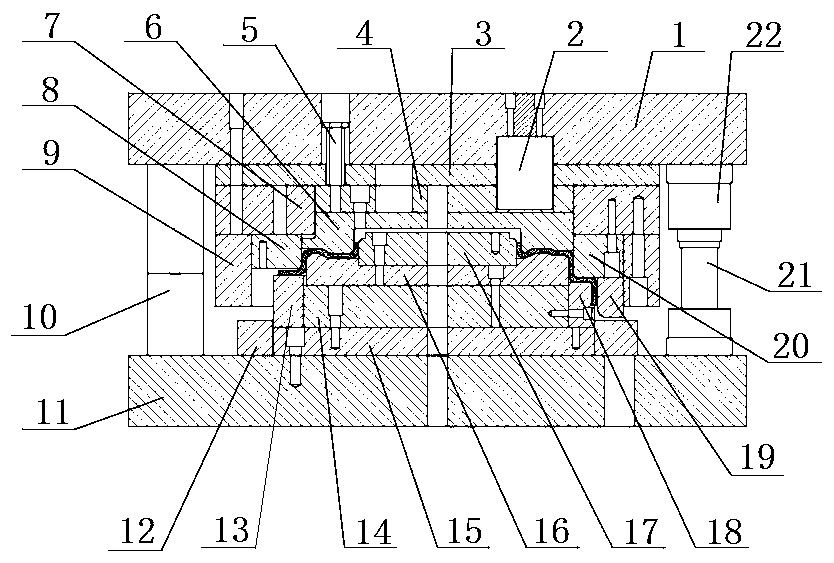

[0022] The present invention adopts the cover plate mold to process the cover plate. First, the planar shape of the cover is dropped on the punching machine through the blanking die; and then the three-dimensional shape of the cover is formed on the press machine through the action of the cover plate mold to obtain a complete cover plate. . The cover plate mold used to cancel the phosphating process in the present invention is mainly composed of an upper template 1, an upper backing plate 3, an upper mold core backing plate 4, a fixing screw 5, an upper mold core 6, a fixing plate 7, and an upper transmission plate pressing block 8 , Mold frame 9, limit mechanism 10, lower template 11, stripping plate 12, lower transmission plate pressing block 13, lower mold core backing plate 14, lower backing plate 15, lower mold core 16, positioning block 17, step structure installation Surface pressing block 18, flanging pressing block 19, upper mounting surface pressing block 20 and guid...

Embodiment 2

[0025]The present invention adopts the cover plate mold to process the cover plate. First, the planar shape of the cover is dropped on the punching machine through the blanking die; and then the three-dimensional shape of the cover is formed on the press machine through the action of the cover plate mold to obtain a complete cover plate. . The cover plate mold used to cancel the phosphating process in the present invention is mainly composed of an upper template 1, an upper backing plate 3, an upper mold core backing plate 4, a fixing screw 5, an upper mold core 6, a fixing plate 7, and an upper transmission plate pressing block 8 , Mold frame 9, limit mechanism 10, lower template 11, stripping plate 12, lower transmission plate pressing block 13, lower mold core backing plate 14, lower backing plate 15, lower mold core 16, positioning block 17, step structure installation Surface pressing block 18, flanging pressing block 19, upper mounting surface pressing block 20 and guide...

Embodiment 3

[0028] The present invention adopts the cover plate mold to process the cover plate. First, the planar shape of the cover is dropped on the punching machine through the blanking die; and then the three-dimensional shape of the cover is formed on the press machine through the action of the cover plate mold to obtain a complete cover plate. . The cover plate mold used to cancel the phosphating process in the present invention is mainly composed of an upper template 1, an upper backing plate 3, an upper mold core backing plate 4, a fixing screw 5, an upper mold core 6, a fixing plate 7, and an upper transmission plate pressing block 8 , Mold frame 9, limit mechanism 10, lower template 11, stripping plate 12, lower transmission plate pressing block 13, lower mold core backing plate 14, lower backing plate 15, lower mold core 16, positioning block 17, step structure installation Surface pressing block 18, flanging pressing block 19, upper mounting surface pressing block 20 and guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com