Mechanical seal online electronic monitoring system

A mechanical seal and monitoring system technology, applied in transmission systems, liquid tightness measurement using liquid/vacuum degree, measuring devices, etc., can solve the problems of reduced mechanical seal effect, reduced structural connection quality, and affecting the production process, etc., to achieve Small energy consumption, convenient embedded installation, simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

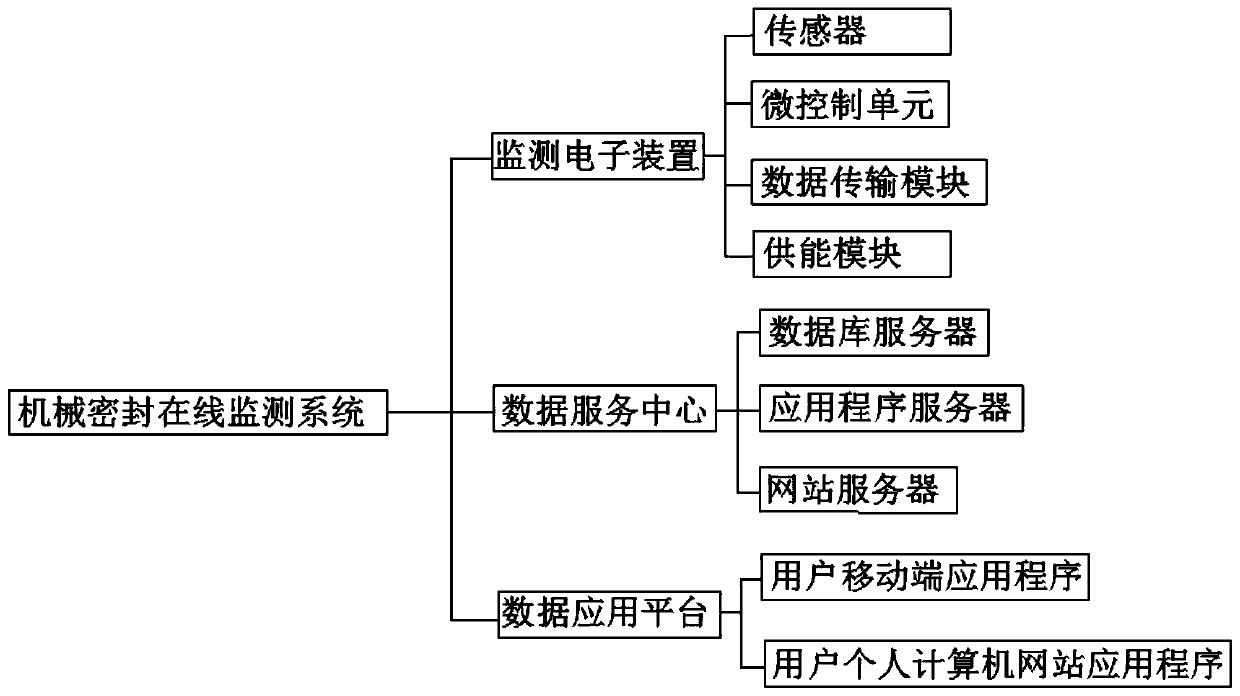

[0027] The mechanical seal online electronic monitoring system such as figure 1 It includes the monitoring electronic device, data service center and data application platform arranged on the corresponding mechanical seal. The monitoring electronic device is used for data detection and detection data transmission operation of mechanical seal performance. The monitoring electronic device includes a temperature sensor, a pressure sensor and a torque sensor. The temperature sensor, the pressure sensor and the torque sensor can be designed as an integrated structure, so as to realize a smaller structure, and then install the corresponding position according to the specific installation position of the mechanical seal. settings to ensure valid performance data testing. The micro-control unit in the monitoring electronic device can select the model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com