Preparation device and preparation method of large-area perovskite solar cell

A solar cell and preparation device technology, which is applied in the field of solar cell technology preparation, can solve the problems of high precision and controllable film growth, spin coating method cannot realize large-scale production, and is not suitable for industrial production, so as to facilitate rapid drying , Saving process operation time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

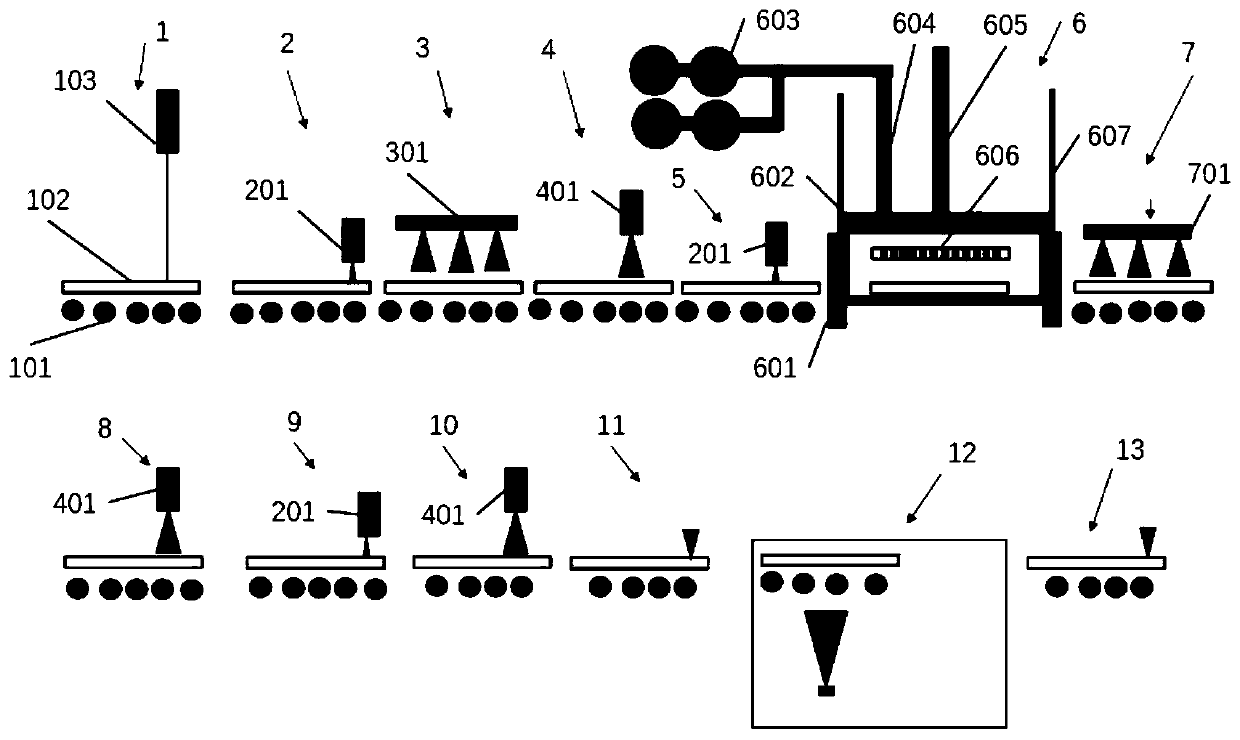

[0034] A large-area perovskite solar cell preparation device according to the present invention comprises in turn: FTO scribing P1 module 1, electron transport layer coating module 2, infrared radiation module 3, electron transport layer cooling module 4, perovskite precursor Solution slit coating module 5, perovskite wet film vacuum distillation module 6, composite light wave annealing module 7, perovskite layer cooling module 8, hole transport layer coating module 9, hole layer drying module 10, mechanical The scribing P2 module 11 , the electrode evaporation module 12 and the mechanical scribing P3 module 13 , and the FTO glass carrier 102 pass through each process module sequentially by using the transfer roller 101 .

[0035] FTO scribing P1 module 1 adopts laser 103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com