Method for forming curved bridge based on BIM combined template support process

A technology of combined templates and curved bridges, applied in special data processing applications, instruments, calculations, etc., can solve the problems of no reuse of steel templates, low economic and social benefits, etc., achieve beautiful and smooth lines, ensure appearance quality, and operate The effect of simple procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The implementation of the present invention is described below through specific specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

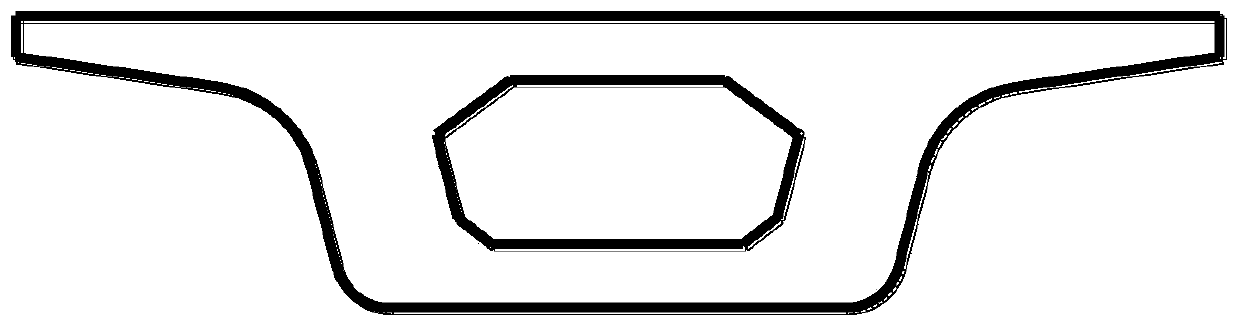

[0039] A curved bridge formed by BIM-based combined formwork support technology ( figure 2 Shown is the method for curved bridge structure schematic diagram of the present invention), comprises the following steps:

[0040] 1) Calculation: Calculate and determine the distance between the supporting structures according to the self-weight of the bridge structure and the weight of the supporting system;

[0041] 2) Modeling: According to the calculated actual distance, the bridge is built on the computer based on BIM technology, combined with the bridge

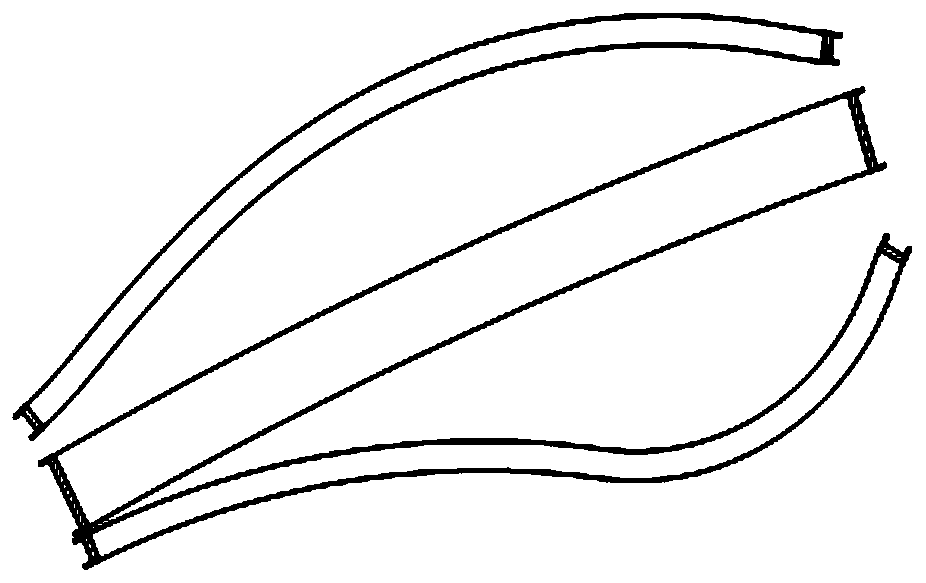

[0042] For special curves and formwork support special construction schemes, see formwork support and formwork dimensions image 3 ;

[0043] 3) Cutting: combined w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com