An environment-friendly dry waste incineration and waste gas treatment system

A waste incineration and exhaust gas treatment technology, applied in the direction of combustion product treatment, incinerator, combustion type, etc., can solve problems such as non-compliance with the plan, pollution, waste discharge is not very environmentally friendly, etc., to improve heat resistance, air filtration Efficient and meet the effect of environmental protection treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

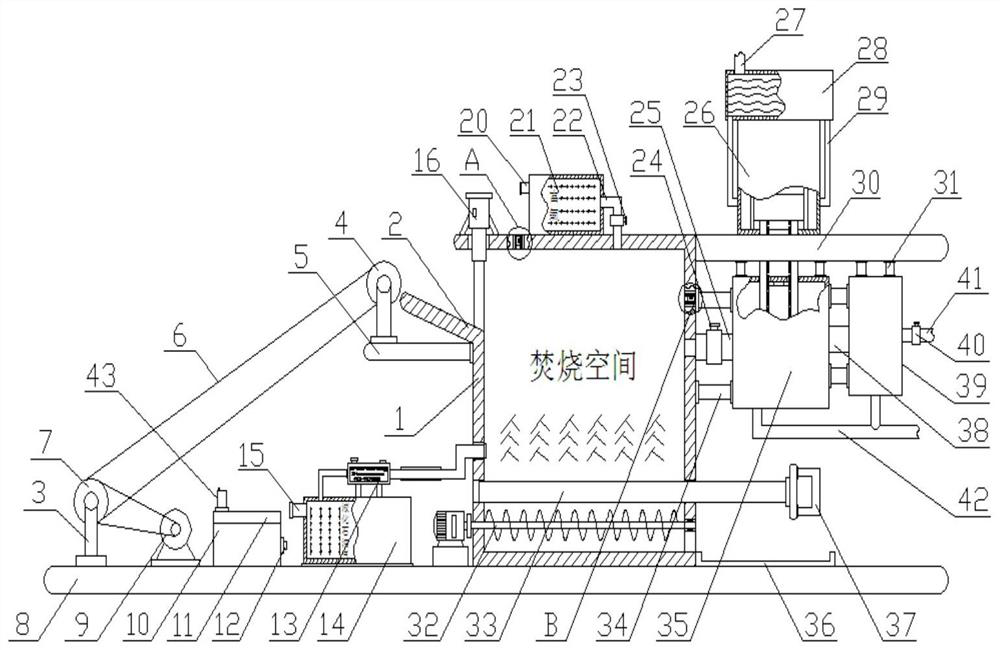

[0046] Example: as attached figure 1 to the attached Figure 16 shown

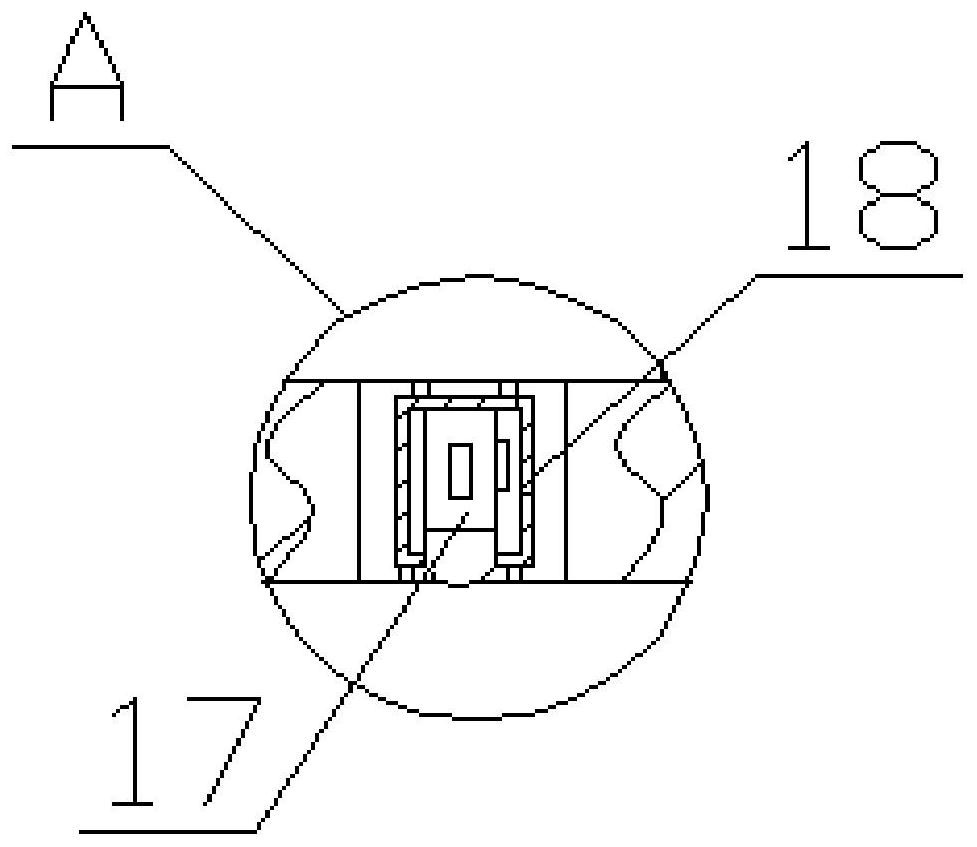

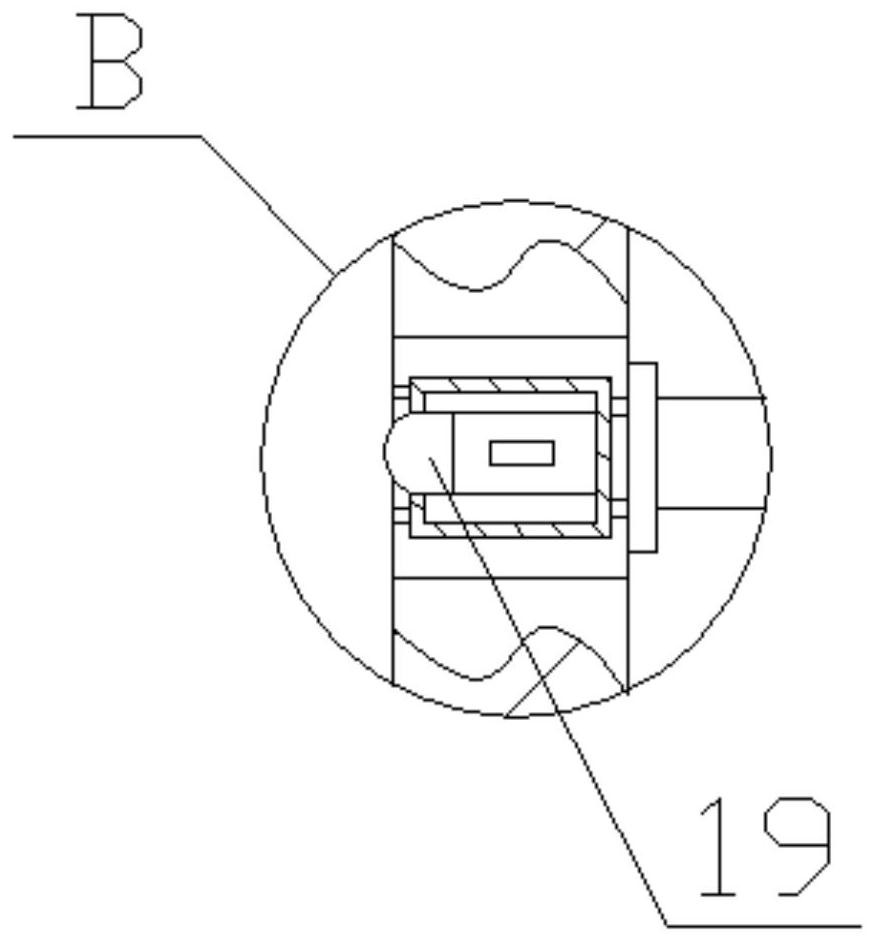

[0047] The present invention provides an environment-friendly dry waste incineration and its waste gas treatment system, comprising an incinerator wall 1, a material guide inclined plate 2, a support frame 3, a No. 1 drive wheel 4, a support plate 5, a conveyor belt 6, and a No. 2 drive wheel 7 , bottom plate 8, material guide motor 9, controller 10, remote control switch group 11, main switch 12, liquefied flamethrower 13, liquefied petroleum tank 14, liquefied gas filling port 15, electric telescopic rod 16, oxygen sensor 17, heat resistance Cover 18, temperature sensor 19, oxygen-enriched filling port 20, oxygen-enriched tank 21, oxygen charging pipe 22, solenoid valve 23 for conducting oxygen, exhaust gas solenoid valve 24, exhaust gas outlet pipe 25, reciprocating cleaning mechanism 26, water charging pipe 27, Water tank 28, water conduit 29, mounting plate 30, stabilizing column 31, discharging mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com