Self-resetting type grinding disc vibration isolation pier device

A self-resetting and grinding disc technology, which is applied in the direction of earthquake resistance, protective buildings/shelters, building components, etc., can solve the problems of dissipating earthquake energy or self-resetting function, life and property safety threats, and low lateral stiffness. To achieve the effect of prolonging the sliding energy consumption, prolonging the self-vibration period, and solving the high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

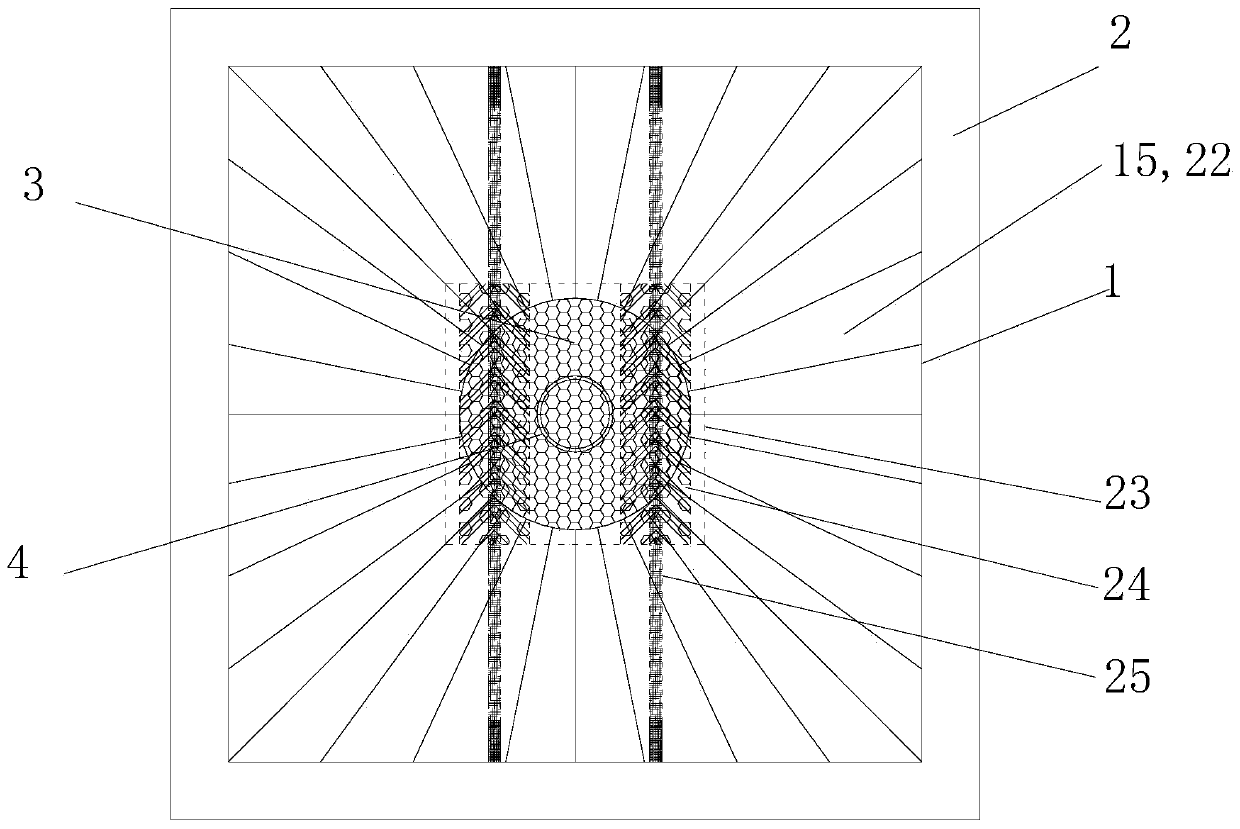

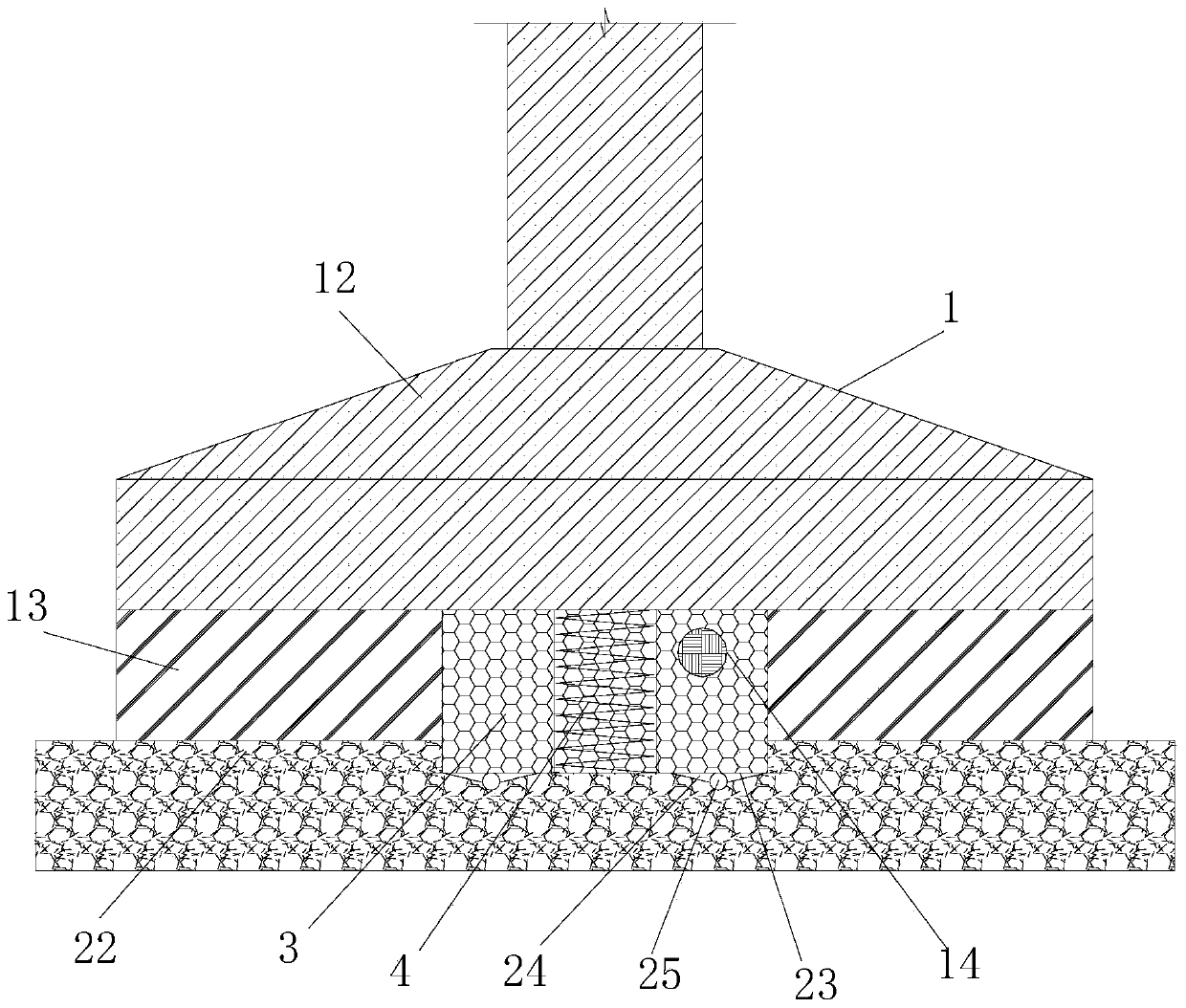

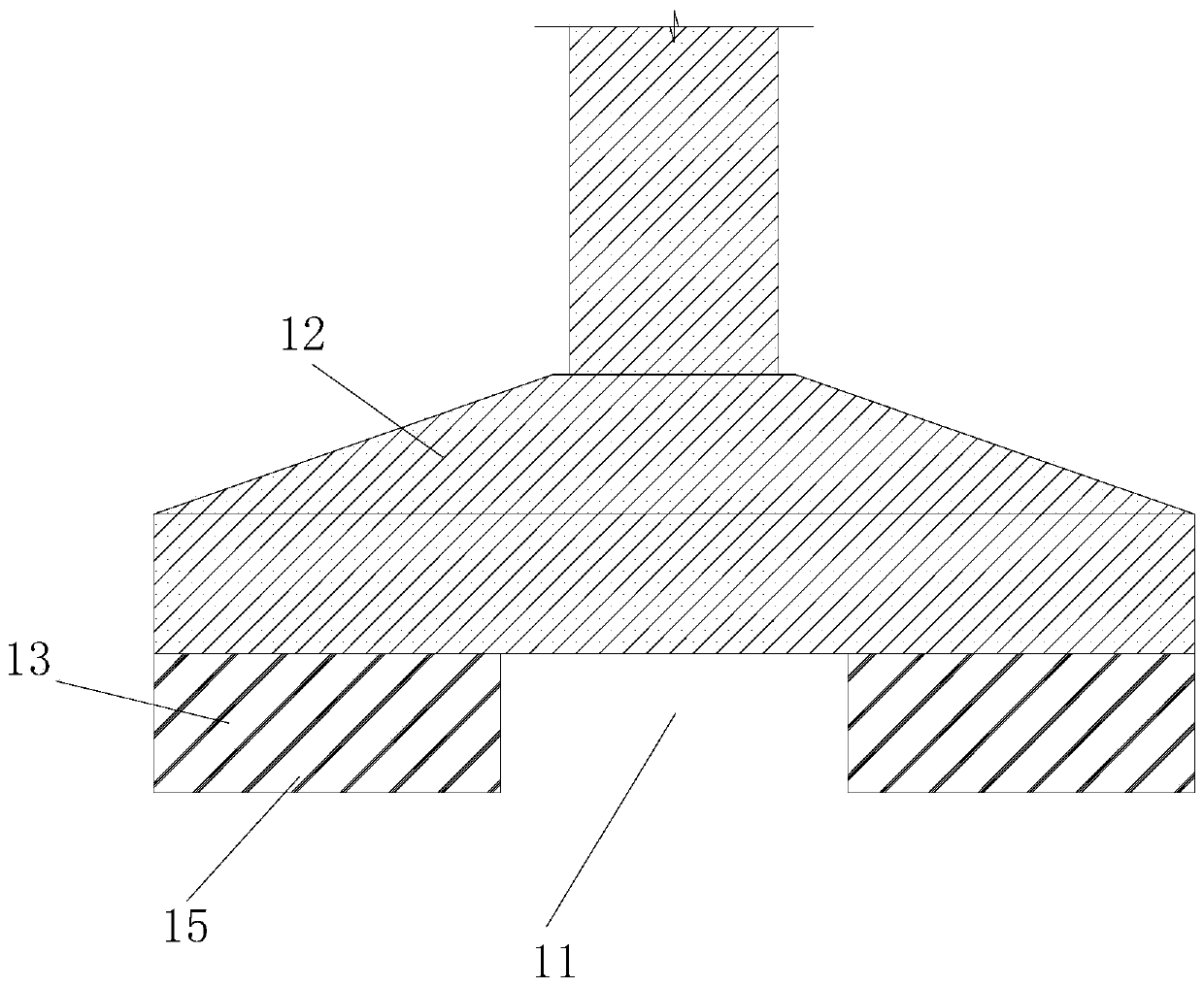

[0019] refer to Figure 1-Figure 6 , the present invention proposes a self-resetting millstone isolation pier device, including an upper pier 1 and a lower pier 2; wherein:

[0020] The upper pier 1 and the lower pier 2 are arranged up and down, the bottom of the upper pier 1 is provided with an upper silo 11, the top of the lower pier 2 is provided with a lower silo 21, and the bottom surface of the upper pier 1 is in contact with the top surface of the lower pier 2 And the upper silo 11 is connected with the lower hopper 21 to form a storage silo, the storage silo is filled with grinding material 3, the central position of the storage silo is provided with a deformation memory elastic member 4, and the upper and lower ends of the deformation memory elastic member 4 are connected to the upper and lower ends respectively. The buttress 1 and the lower buttress 2 are connected. On the bottom surface of the upper pier 1 is provided with an upper groove band 15, one end of a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com