High-plasticity quasi-mesh-shaped structure titanium-based composite material and preparation method thereof

A titanium-based composite material, mesh structure technology, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as difficulty in obtaining reinforcement effects, and achieve the effects of avoiding voids/voids, enhancing reinforcement effects, and high elongation plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

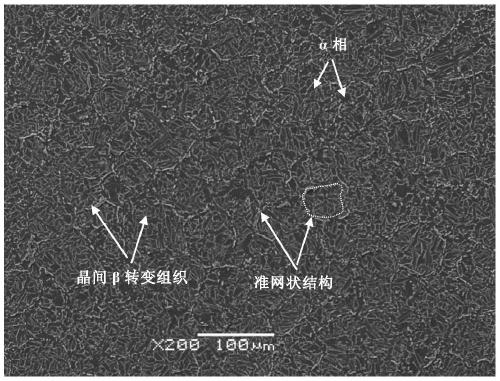

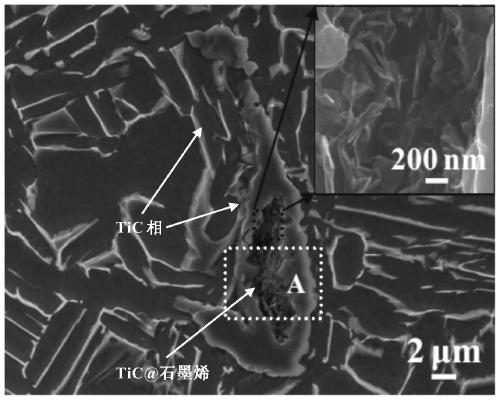

[0036] The highly plastic quasi-reticular titanium-based composite material in this embodiment uses CT20 titanium alloy as the matrix, and uses the in-situ self-generated TiC phase and TiC@graphene of graphene and CT20 titanium alloy matrix as reinforcements. The reinforcements are uniform and Discontinuously distributed at the original β grain boundary of the CT20 titanium alloy matrix, forming a quasi-network structure, the average diameter of the mesh in the quasi-network structure is 60 μm.

[0037] The preparation method of the highly plastic quasi-network structure titanium-based composite material of the present embodiment comprises the following steps:

[0038] Step 1. Surface pretreatment of CT20 titanium alloy powder: immerse 220 g of CT20 titanium alloy spherical powder particles in a 2M mixed acid solution for acid leaching for 15 minutes. The mixed acid solution consists of a hydrochloric acid solution with a mass concentration of 37% and a mass concentration of 40...

Embodiment 2

[0050] The highly plastic quasi-reticular titanium-based composite material in this embodiment uses CT20 titanium alloy as the matrix, and uses the in-situ self-generated TiC phase and TiC@graphene of graphene and CT20 titanium alloy matrix as reinforcements. The reinforcements are uniform and Discontinuously distributed at the original β grain boundary of the CT20 titanium alloy matrix, forming a quasi-network structure, the average diameter of the mesh in the quasi-network structure is 150 μm.

[0051] The preparation method of the highly plastic quasi-network structure titanium-based composite material of the present embodiment comprises the following steps:

[0052] Step 1, CT20 titanium alloy powder surface pretreatment: immerse 220g of CT20 titanium alloy spherical powder particles into a 5M mixed acid solution for acid leaching for 5 minutes, and the mixed acid solution consists of a hydrochloric acid solution with a mass concentration of 37% and a mass concentration of ...

Embodiment 3

[0058] The highly plastic quasi-network structure titanium-based composite material in this embodiment uses TA1 pure titanium as the matrix, and uses the in-situ self-generated TiC phase and TiC@graphene of graphene and TA1 pure titanium matrix as reinforcements, and the reinforcements are uniform and Discontinuously distributed at the original β grain boundary of the TA1 pure titanium matrix, forming a quasi-network structure, the average diameter of the mesh in the quasi-network structure is 100 μm.

[0059] The preparation method of the highly plastic quasi-network structure titanium-based composite material of the present embodiment comprises the following steps:

[0060] Step 1. Surface pretreatment of TA1 pure titanium powder: immerse 220 g of TA1 pure titanium spherical powder particles into a 3M mixed acid solution for acid leaching for 10 minutes. The mixed acid solution consists of a hydrochloric acid solution with a mass concentration of 37% and a mass concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com