Epoxy resin adhesive and preparation method thereof

A technology of epoxy resin glue and epoxy resin, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of slow curing reaction speed, unsatisfactory, and uncurable adhesive, and achieve the preparation method Simple, Gentle Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

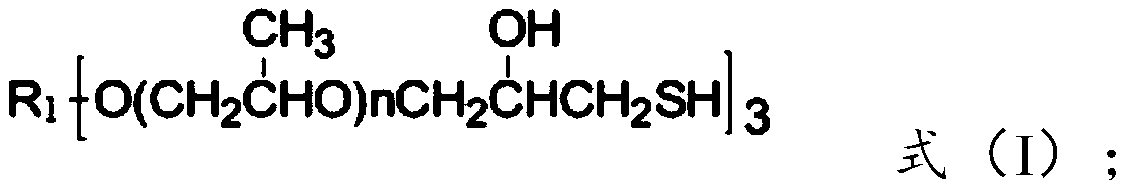

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a preparation method of the epoxy resin adhesive described in the above technical scheme, comprising the following steps:

[0050] a) mixing the amine curing agent and mercaptan to obtain a mixture;

[0051] b) adding epoxy resin to the mixture obtained in step a), performing degassing and stirring to obtain an epoxy resin adhesive.

[0052] In the present invention, firstly, the amine curing agent and mercaptan are mixed to obtain a mixture. In the present invention, the amine curing agent and mercaptan are the same as those described in the above technical solution, and will not be repeated here.

[0053]In the present invention, the mixing device preferably adopts a reactor known to those skilled in the art; the mixing method is preferably high-speed stirring; the rotating speed of the high-speed stirring is preferably 1500r / min~3500r / min, more preferably 3000r / min.

[0054] In the present invention, the mixing temperature is pr...

Embodiment 1

[0071] The formula quantity of the raw materials used in Example 1 is shown in Table 1.

[0072] The formula quantity of raw material used in table 1 embodiment 1

[0073] raw material Mass / kg 1,2-Dimethylpropylamine 5 Thiol 41 Epoxy resin E20 48

[0074] (1) Add 1,2-dimethylpropylamine and mercaptan into the reaction kettle, and perform high-speed stirring at 3000r / min at 25°C for 1.5h to 2h to disperse the two evenly to obtain a mixture;

[0075] (2) In the mixture obtained in step (1), slowly add epoxy resin E20 within 4 minutes. After the addition is completed, degas and stir at 3000r / min and 20°C for 3 minutes to 5 minutes to obtain epoxy resin glue adhesive.

[0076] After testing, the epoxy resin adhesive provided by Example 1 of the present invention has a gel time of 13 minutes at room temperature, a curing time of 19 minutes, a tensile shear strength of 9.7 MPa, and a tensile shear strength of 7.6 MPa after being soaked in machine o...

Embodiment 2

[0078] The formulation amount of the raw materials used in Example 2 is shown in Table 2.

[0079] The formula quantity of raw material used in table 2 embodiment 2

[0080] raw material Mass / kg N,N-Dimethylethanolamine 4 Thiol 36 Epoxy resin E20 52

[0081] (1) Add N,N-dimethylethanolamine and mercaptan into the reaction kettle, and carry out high-speed stirring at a speed of 3000r / min at 25°C for 1.5h to 2h to disperse the two evenly to obtain a mixture;

[0082] (2) In the mixture obtained in step (1), slowly add epoxy resin E20 within 4 minutes. After the addition is completed, degas and stir at 3000r / min and 20°C for 3 minutes to 5 minutes to obtain epoxy resin glue adhesive.

[0083] After testing, the epoxy resin adhesive provided in Example 2 of the present invention has a gel time of 12 minutes at room temperature, a curing time of 17 minutes, a tensile shear strength of 10.6 MPa, and a tensile shear strength of 9.7 MPa after being s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

| Gel time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com