Heat sealing material and preparation method thereof

A heat-sealing and heat-insulating filler technology, which is applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve the problems of insufficient resilience of heat-sealing materials, and achieve low equipment cost, strong process adaptability, and high The effect of performance and low-cost manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

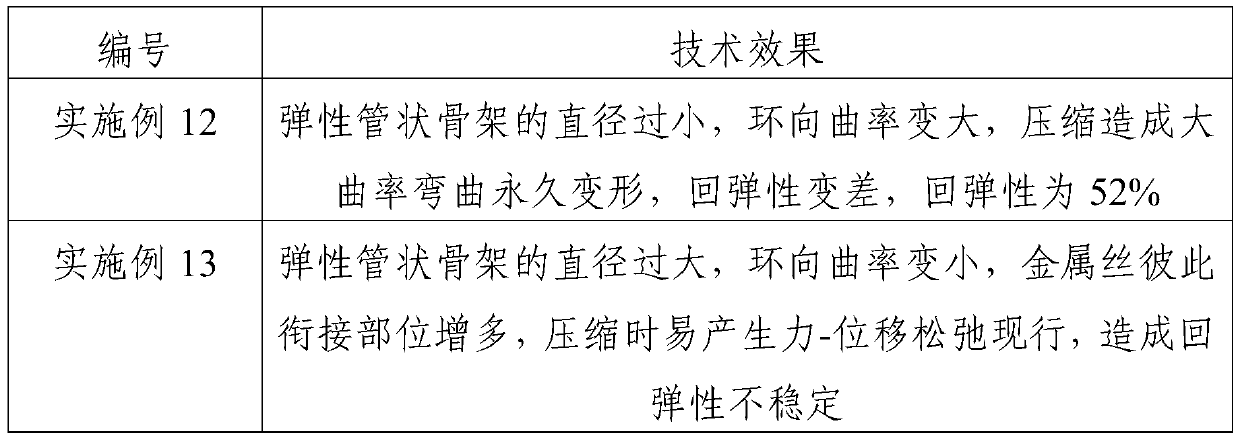

[0052] In a second aspect, the present invention provides a method for preparing the aforementioned heat-sealing material, comprising the following steps:

[0053] (1) The step of providing the metal wire: the selected metal material is continuously drawn according to the wire drawing process to make the metal wire.

[0054] In this step, the metal material may be any one of stainless steel, copper alloy, nickel-based alloy, and titanium alloy. The wire drawing process may be any one of cold drawing, cutting and beam melting. The wire diameter of the metal wire is preferably 0.08 mm to 0.25 mm.

[0055] (2) The steps of skeleton weaving and forming: select the braiding tool with the same diameter as the round tube and the elastic tubular skeleton, and crochet the metal wire bundles composed of metal wires through the crochet needles of the braiding tool one by one and in a ring direction. In the process, each mesh of the previous circle is continuously crocheted, and the num...

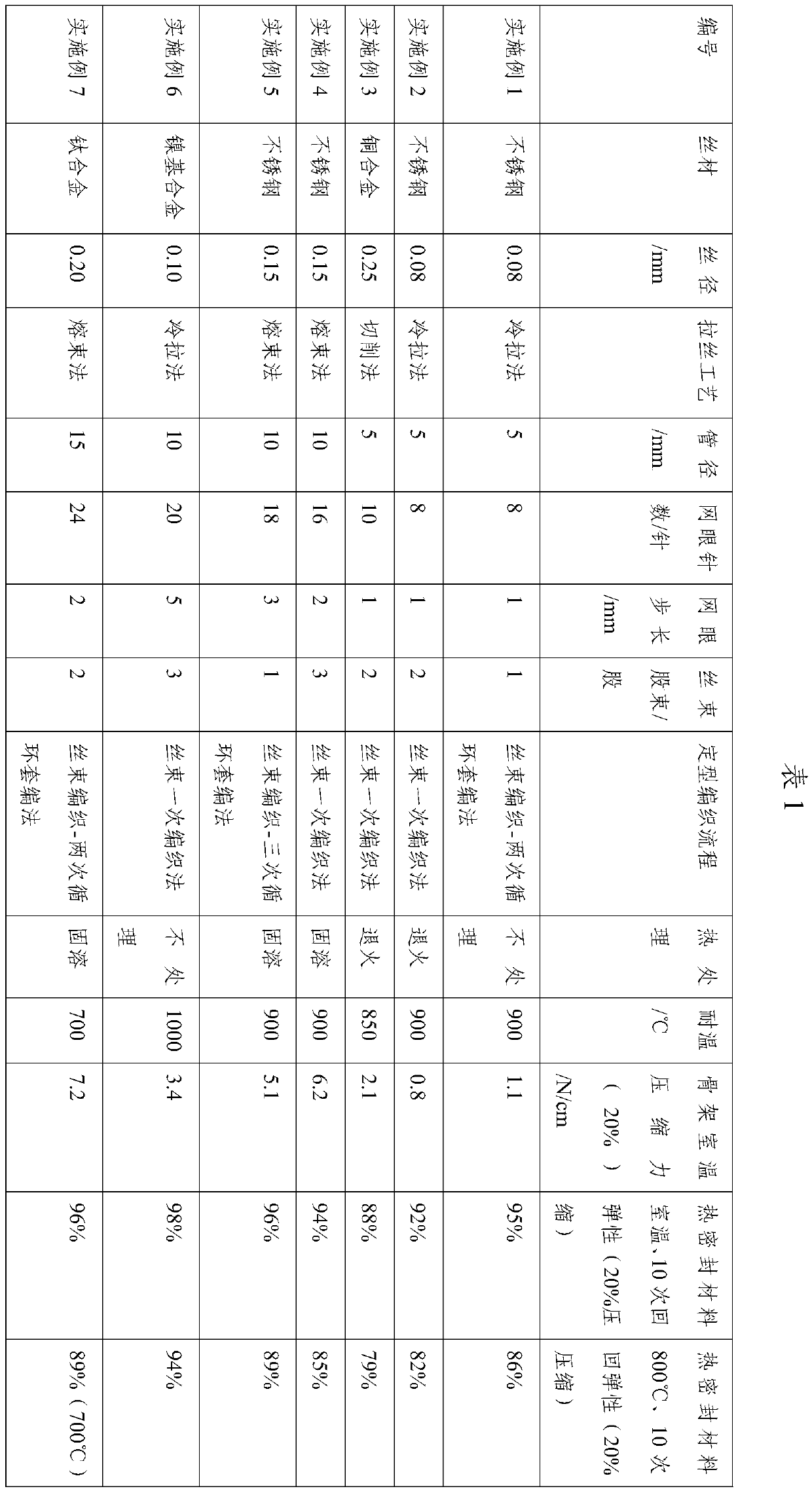

Embodiment 1

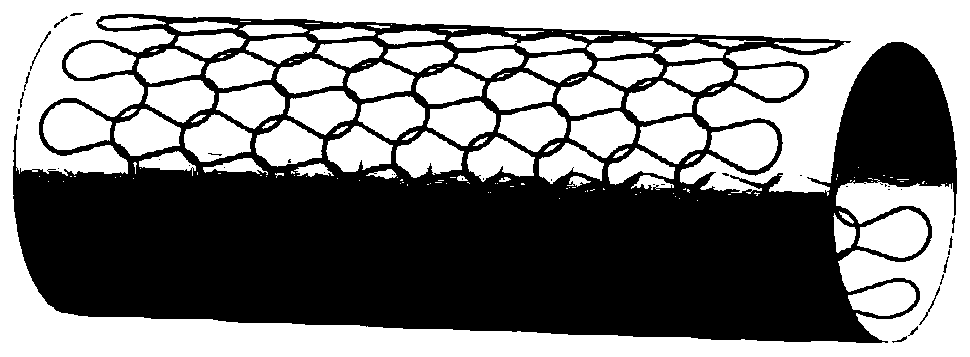

[0073] The heat-sealing material provided in this embodiment includes an elastic tubular skeleton, an inner core made of heat-insulating filler inorganic fiber cotton filled inside the elastic tubular skeleton, and an outer layer made of heat-insulating cloth wrapped outside the elastic tubular skeleton . The elastic tubular skeleton is a circular tubular structure with meshes woven by wire hooks. The meshes are arc-shaped meshes with gradually narrowing open ends, which can be described as Ω-shaped.

[0074] The preparation method of this heat sealing material comprises the steps:

[0075] S1. Metal wire drawing: the metal material is selected as stainless steel, and it is cold-drawn to form a wire to prepare a stainless steel wire with a wire diameter of 0.08mm.

[0076] S2. Skeleton weaving forming: select the weaving tooling with a circular network tube diameter of 5mm, pass the stainless steel wire with a wire diameter of 0.08mm and 1 strand through the crochet needles of ...

Embodiment 2

[0082] The heat-sealing material provided by this embodiment is the same as that of Embodiment 1 in terms of macroscopic structure, including an elastic tubular skeleton, an inner core made of heat-insulating filler inorganic fiber cotton filled inside the elastic tubular The outer part of the insulation cloth. The elastic tubular skeleton is a circular tubular structure with meshes woven by wire hooks. The meshes are arc-shaped meshes with gradually narrowing open ends, which can be described as Ω-shaped.

[0083] The preparation method of this heat-sealing material is basically the same with the preparation method of embodiment 1, and difference is:

[0084] The metal wire bundle is 2 strands, and the weaving process adopts the one-time weaving method of the wire bundle, and a heat treatment step is also included between S3 and S4, and the heat treatment adopts annealing.

[0085] The elastic tubular framework in the heat-sealing material prepared by this preparation method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com