A production process of brass wire

A production process and technology of brass wire, which is applied in the direction of manufacturing tools, metal processing equipment, metal wire drawing, etc., can solve the problem of affecting the surface quality of copper wire drawing, the drawing size accuracy, the easy damage of the connection between the main drive shaft and the drawing water tank, and drawing problems. Process synchronization is difficult to control and other issues, to achieve the effect of reducing leakage frequency, small footprint, and easy processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

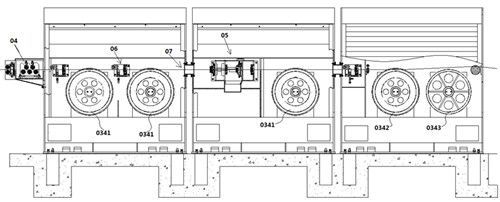

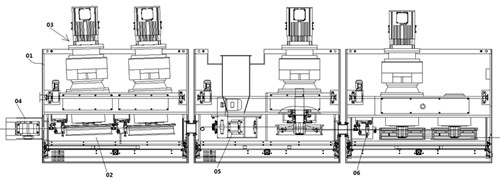

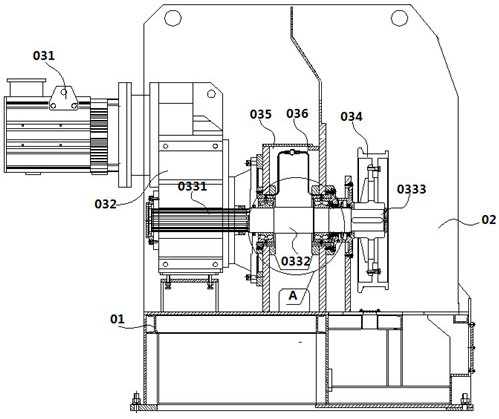

[0046] Such as figure 1 and figure 2 Shown, the production technology of a kind of brass wire of present embodiment, its steps are as follows:

[0047] Step 1. Raw material smelting: After weighing the waste copper and zinc ingots according to the composition standard of H65 brass, first put the waste copper into the power frequency cored induction heating furnace for melting, then add the zinc ingots to melt, and stir, After slag removal and component inspection, the molten copper water is poured into the water-cooled crystallizer, and then the wire drawing tractor pulls and casts a Φ12mm copper rod, and the wire is taken up by the wire take-up rack;

[0048] Step two, wire drawing:

[0049] (1) Move the above-mentioned Φ12mm copper rod after the wire is taken up to the wire-releasing device and release the wire under the action of multiple guide wheels on the wire-releasing device;

[0050] (2) The copper rod after the wire is drawn to the giant wire drawing machine for wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com