High density fiber rope combined sweeper

A technology of high-density fibers and cleaners, which is applied in the direction of cleaning devices, transportation and packaging, and conveyor objects. It can solve the problems of scratches on scrapers, inability to clean the working surface of the belt, and poor performance, and achieve the effect of low sliding coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

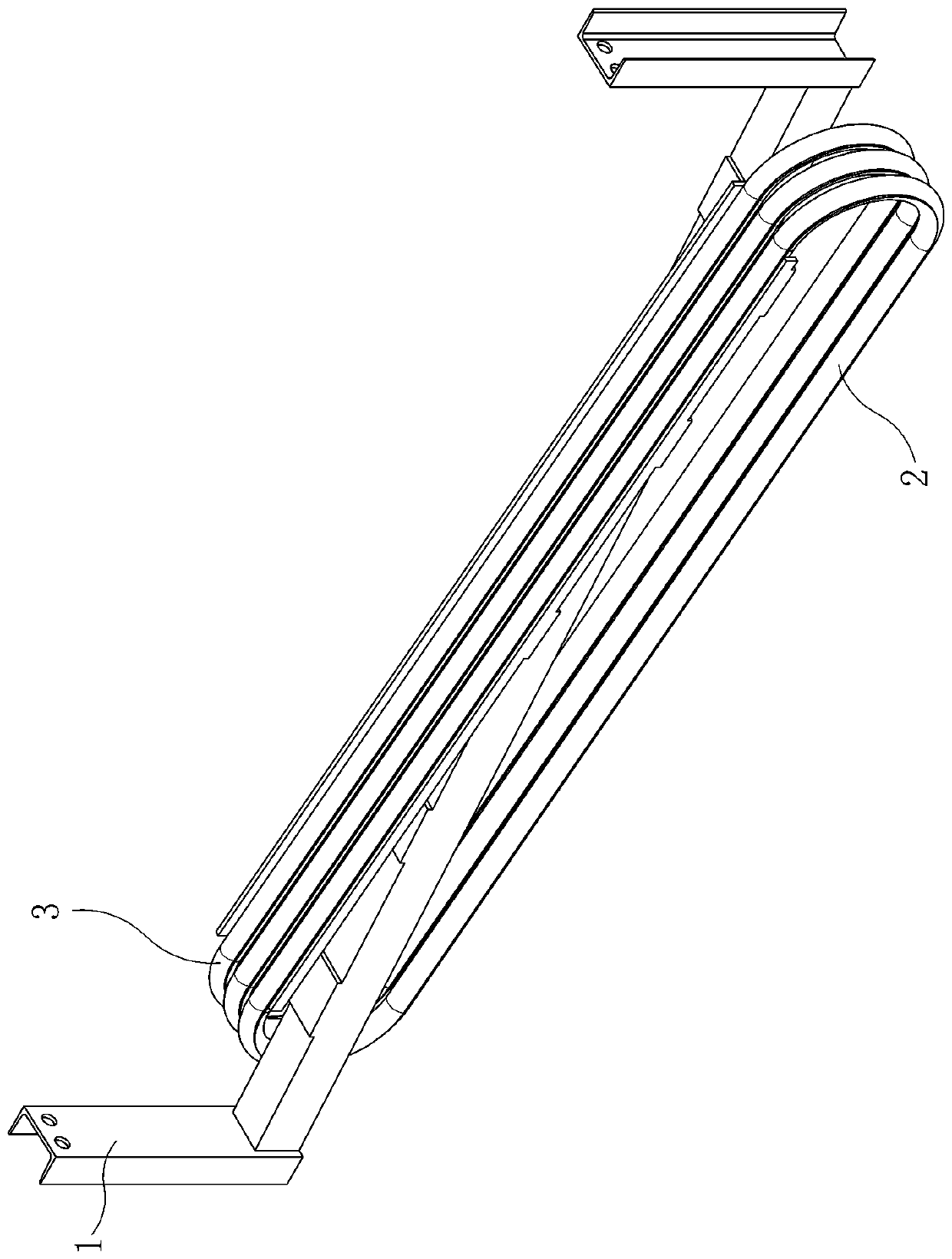

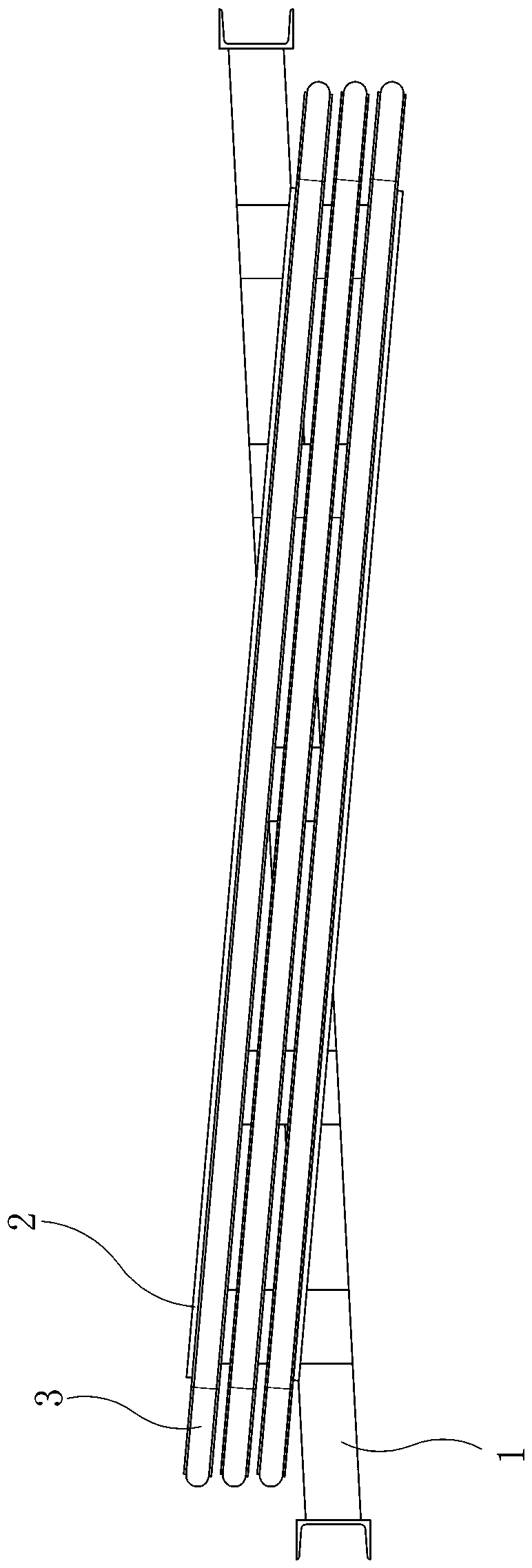

[0026] Such as Figure 1-Figure 4 Shown, the present invention is a kind of high-density fiber rope combination cleaner, comprises cleaning frame 1, three slide rails 2, three cleaning ropes 3.

[0027] The cleaning frame 1 is fixedly installed on the frame 10 in the belt conveyor and is located below the belt 20 in the belt conveyor. to combine Figure 8 As shown, the slide rail is a closed back-shaped component, and its cross-section is semicircular arc-shaped, and three slide rails 2 are obliquely installed on the cleaning frame 1; the cleaning rope 3 is back-shaped, and its cross-section It is circular, and the three cleaning ropes 3 are slid on the three slide rails 2 respectively, and the centerlines of the three cleaning ropes 3 intersect obliquely with the section of the belt 20; in this embodiment, the centerlines of the cleaning ropes 3 and the belt The angle between the oblique intersections of the 20 sections is 5°-8°. The three cleaning ropes 3 are made of fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com