Controlled production method for pickling-free SWRH82B hot rolled wire rod oxidized iron sheet

A technology for iron oxide scale and hot-rolled wire rod, applied in rolling mill control devices, metal rolling, roll speed control, etc., can solve the problems of high processing cost, labor cost, environmental pollution, etc. Quality, the effect of improving the adaptability of wire rod products and the low-cost competitiveness of users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

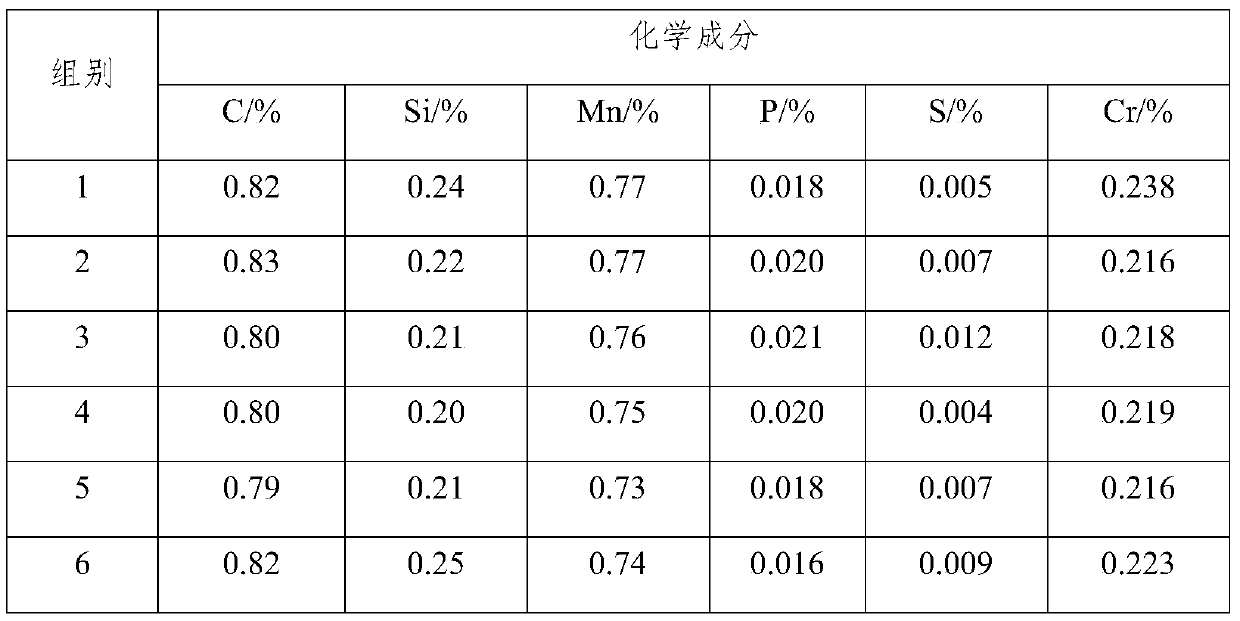

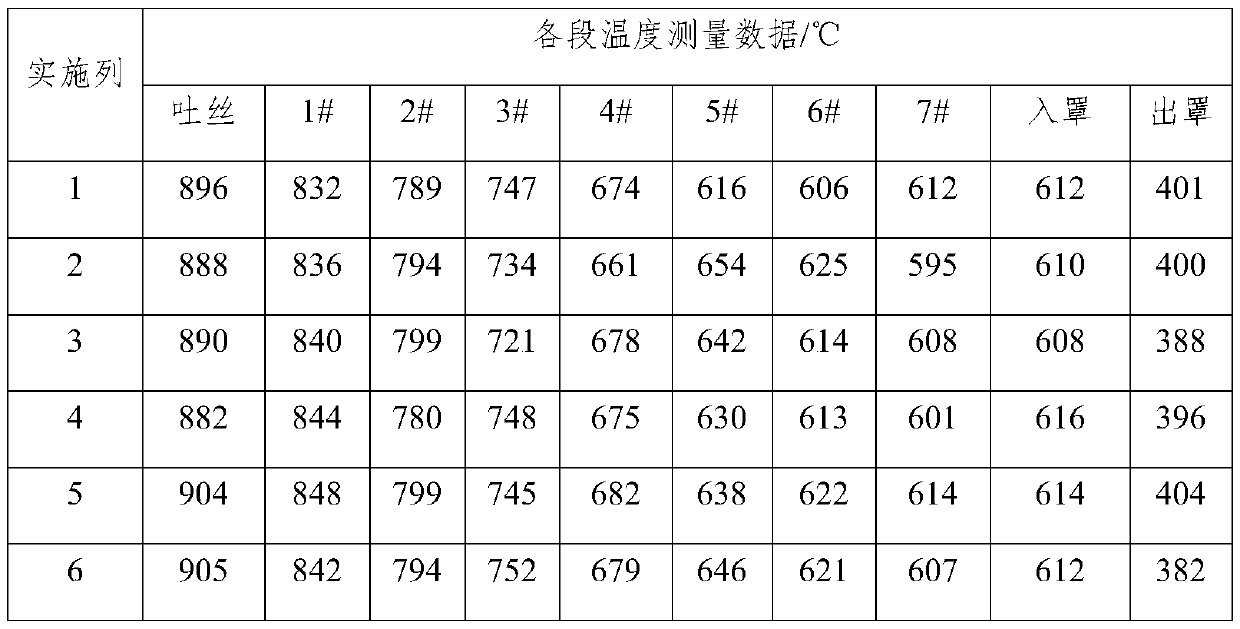

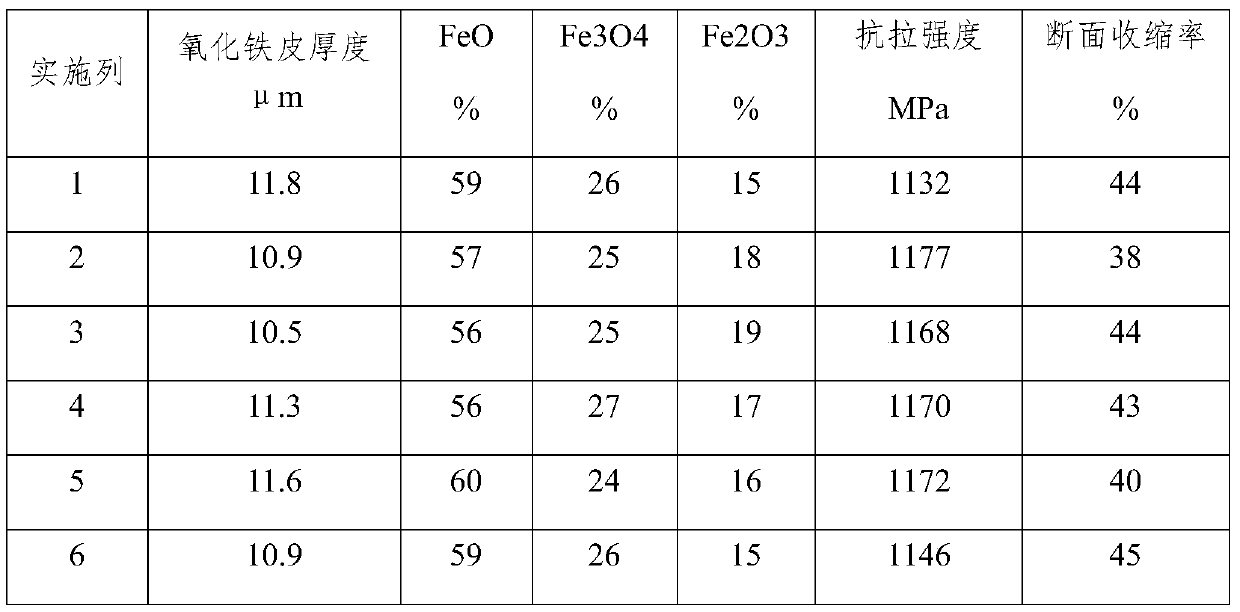

Embodiment 1

[0017] A control production method of pickling-free SWRH82B hot-rolled wire rod oxide scale, comprising the following steps: rolling temperature control → water penetration control cooling after rolling → silk spinning temperature control → roller table speed control → fan and air cooling control; The heating temperature of the heating furnace in the rolling temperature control is 1150°C; the starting rolling temperature is 1000°C; the finishing rolling temperature is 900°C; all the 5-stage water-through water tanks in the water-through-cooling after-rolling control are opened, and the water is passed evenly, and the recovery temperature is ≤30°C , weak water penetration at the end; the spinning temperature is controlled at 880°C; the air-cooled linear velocity range in the roller table speed control is 0.5m / s, the phase change position is 0.9m / s, and the speed in the heat preservation cover is 0.5m / s , the other speed is 0.7m / s; the air volume control in the fan and air coolin...

Embodiment 2

[0020] A control production method of pickling-free SWRH82B hot-rolled wire rod oxide scale, comprising the following steps: rolling temperature control → water penetration control cooling after rolling → silk spinning temperature control → roller table speed control → fan and air cooling control; The heating temperature of the heating furnace in the rolling temperature control is 1210°C; the rolling start temperature is 1050°C; the finishing rolling temperature is 930°C; all the 5-stage water passing tanks in the water passing and cooling after rolling are opened, the water is passed evenly, and the recovery temperature is ≤30°C , weak water penetration at the end; the spinning temperature is controlled to be 920°C; the air-cooling linear velocity in the roller table speed control is 0.9m / s, the phase transition position is 0.9m / s, and the speed in the heat preservation cover is 0.5m / s, Other speeds are 0.7m / s; the air volume control in the fan and air cooling control is 50%, ...

Embodiment 3

[0023] A control production method of pickling-free SWRH82B hot-rolled wire rod oxide scale, comprising the following steps: rolling temperature control → water penetration control cooling after rolling → silk spinning temperature control → roller table speed control → fan and air cooling control; The heating temperature of the heating furnace in the rolling temperature control is 1180°C; the rolling start temperature is 1025°C; the finishing rolling temperature is 920°C; all the 5-stage water passing tanks in the water passing and cooling after rolling are opened, the water is passed evenly, and the recovery temperature is ≤30°C , weak water penetration at the end; the spinning temperature is controlled to be 900°C; the air-cooling line speed in the roller table speed control is 0.7m / s, the phase change position is 0.9m / s, and the speed in the heat preservation cover is 0.5m / s, Other speeds are 0.7m / s; the air volume control in the fan and air-cooling control is 45%, and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com