Non-woven microwave sterilization equipment and non-woven processing system

A technology of microwave sterilization and non-woven fabrics, which is applied in the microwave field, can solve the problems of radiation leakage, low safety and reliability, etc., and achieve the effect of reducing leakage and improving safety and reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

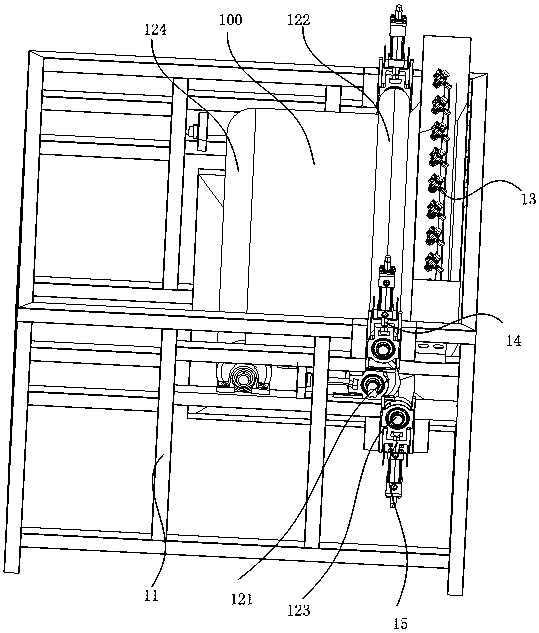

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] The non-woven fabric processing system usually requires the following treatment of the non-woven fabric: the non-woven fabric is first unwinded through the unwinding machine, and then the unrolled non-woven fabric is coated with a solution of functional raw materials, and the coating is applied again. The non-woven fabric with the solution is sterilized. After the non-woven fabric is sterilized, it can be further processed according to the different types of masks. The mask is divided into: wet mask and dry mask. For the wet mask, it is sterilized and then cut and packaged; for the dry mask, it needs to be dehydrated after sterilizing, so that the moisture content of the non-woven fabric is reduced to form a dry mask. For the coating solution and sterilization of the facial mask, the present invention has correspondingly designed spraying equipment and micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com