Silicon wafer surface treatment method for graphene in-situ growth

An in-situ growth, silicon wafer surface technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effect of improving capacity, helping mass production, and repeating the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The silicon chip surface treatment method that is used for graphene in-situ growth of the present embodiment specifically comprises the following steps:

[0036] (1) Take (100) silicon wafers for growth, place them in deionized water for simple ultrasonic cleaning for 1 min, and then immerse in dilute hydrofluoric acid with a volume ratio of 1:100 for 1 min;

[0037] (2) Take out the silicon wafer, rinse the surface with deionized water, and dry it with 0.5MPa high-pressure nitrogen;

[0038] (3) Immerse the silicon wafer in 0.1M p-diphenol methanol solution for 1 hour;

[0039] (4) Take out the silicon chip and rinse it three times with absolute ethanol solution;

[0040] (5) After rinsing, the silicon wafer was blown dry with 0.5MPa high-pressure nitrogen, placed in a tube furnace, and grown graphene by chemical vapor deposition for 30 minutes to obtain a large number of graphene crystal nuclei.

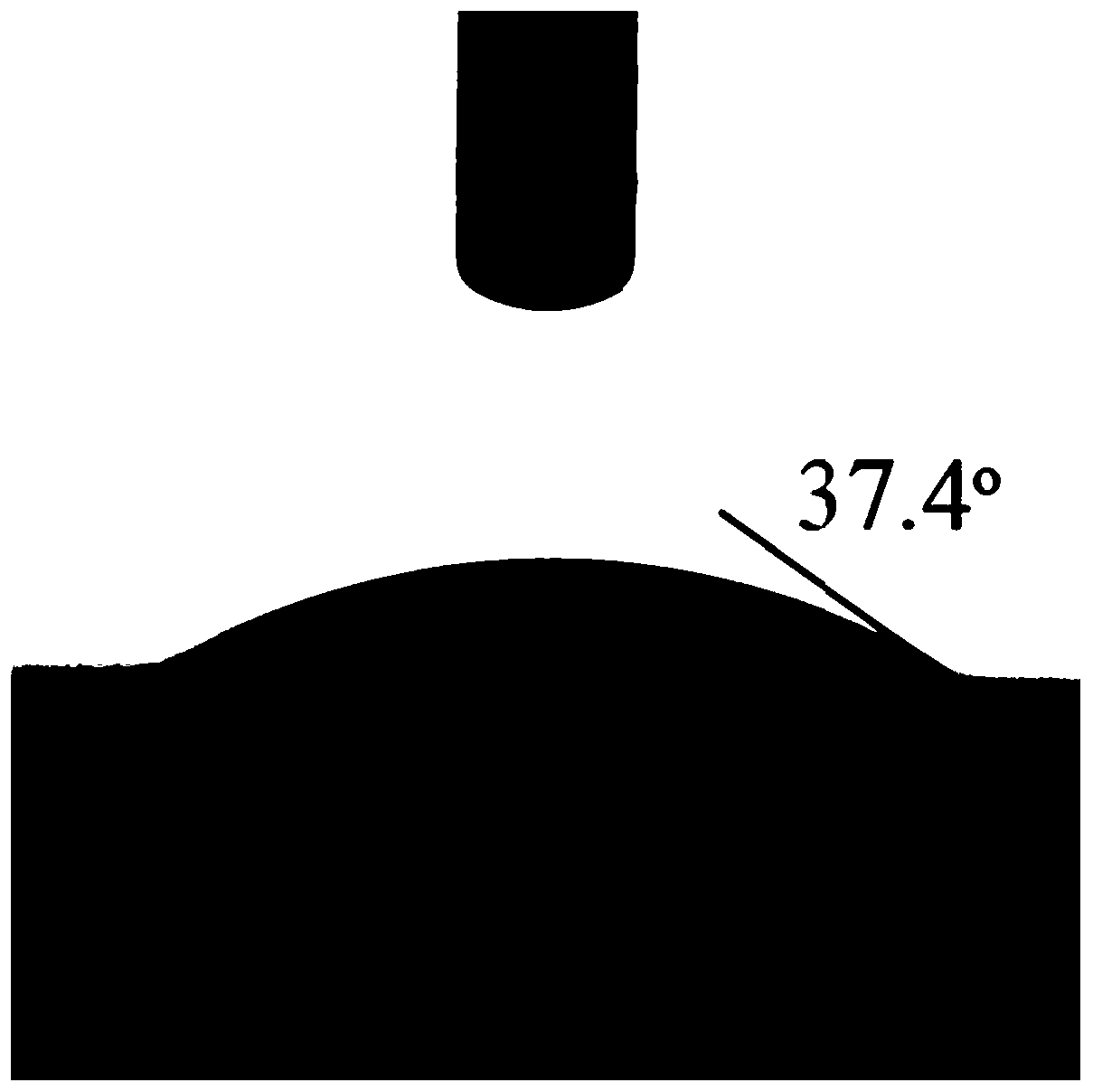

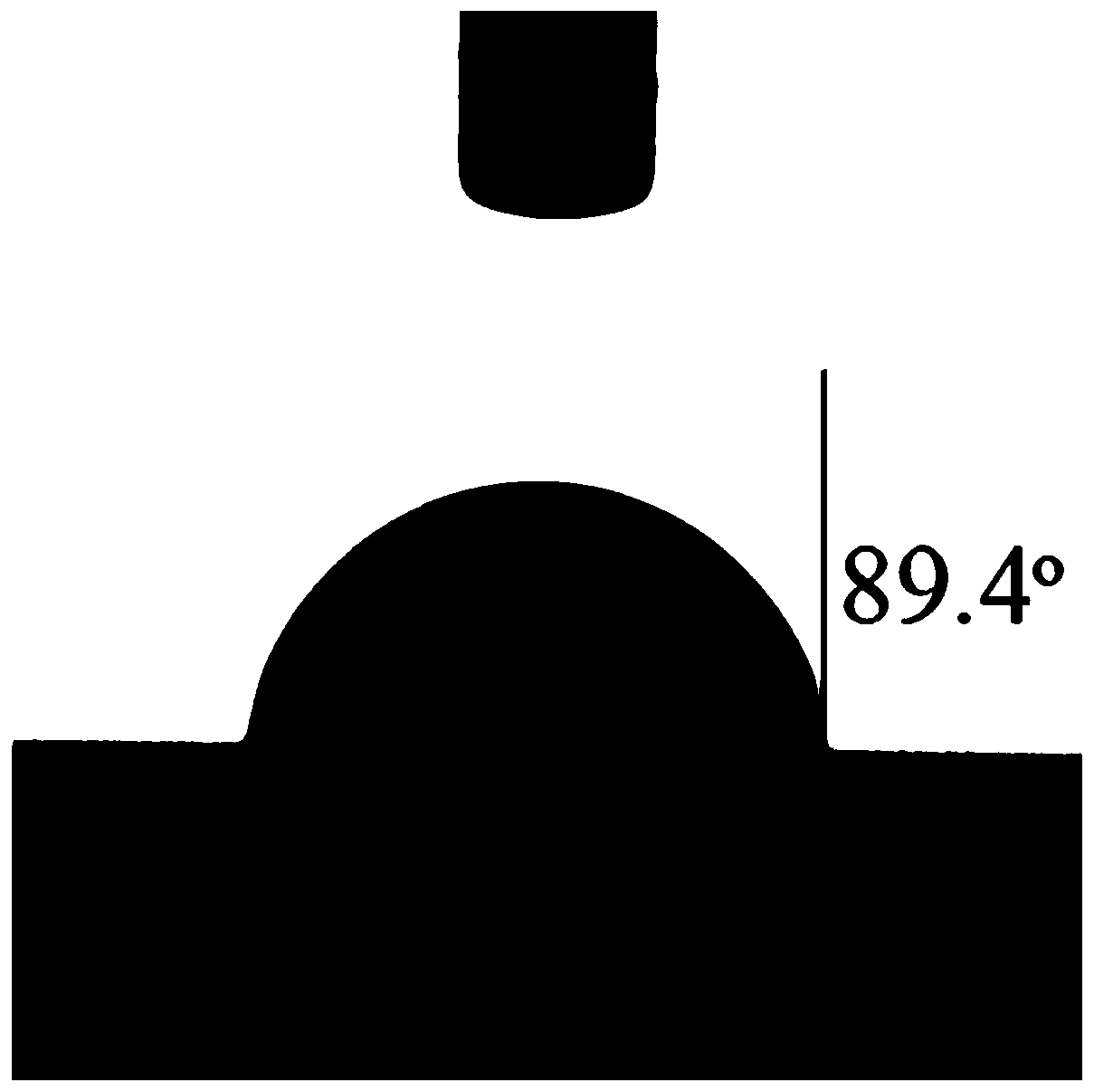

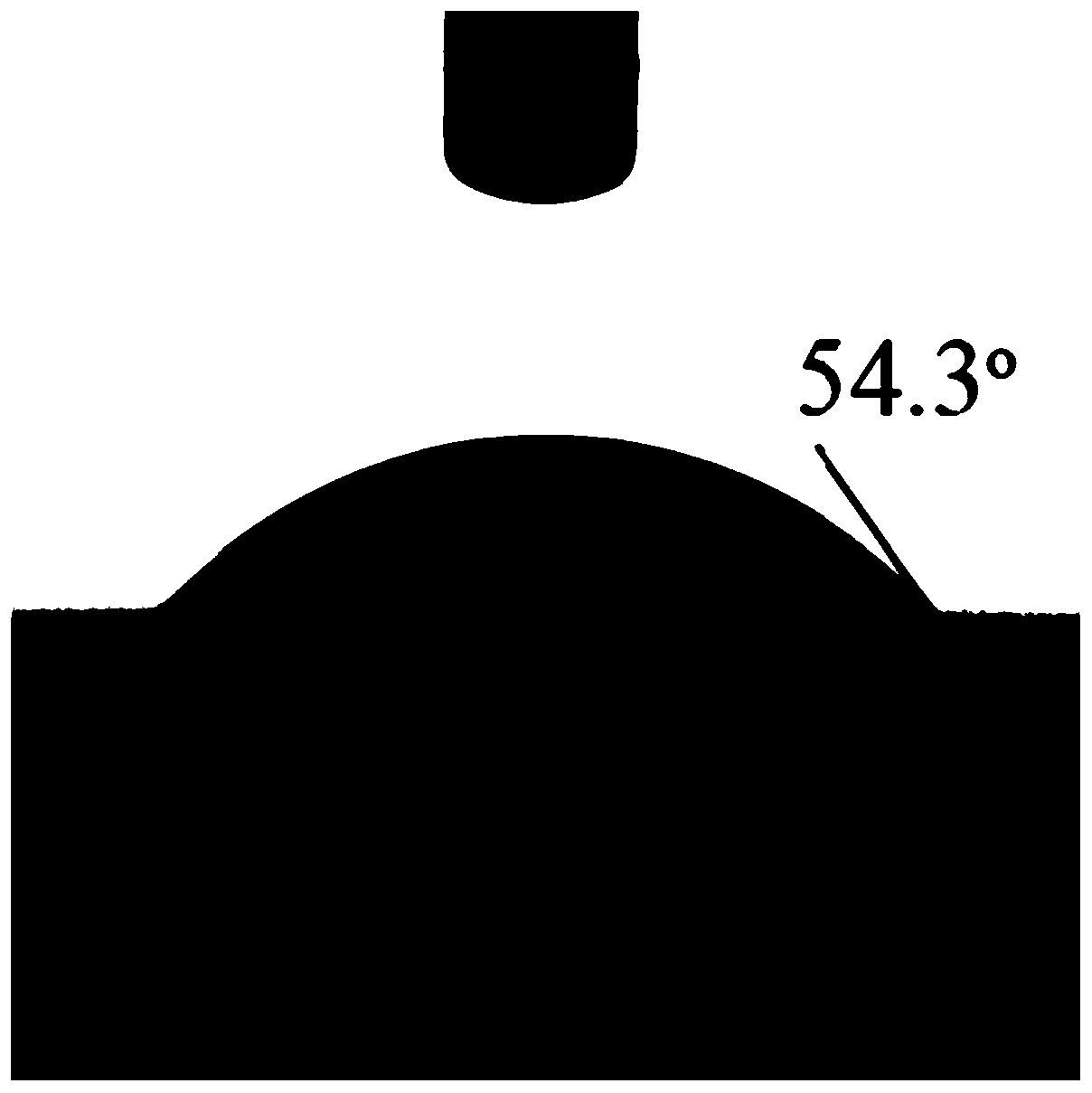

[0041] The water contact angle measuring instrument was used to chara...

Embodiment 2

[0046] The silicon chip surface treatment method that is used for graphene in-situ growth of the present embodiment specifically comprises the following steps:

[0047] (1) Take (100) silicon wafers for growth, place them in deionized water for simple ultrasonic cleaning for 1 min, and then immerse in dilute hydrofluoric acid with a volume ratio of 1:50 for 1 min;

[0048] (2) Take out the silicon wafer, rinse the surface with deionized water, and dry it with 0.5MPa argon;

[0049] (3) Immerse the silicon wafer in 0.1M phenol-methanol solution for 1 hour;

[0050] (4) Take out the silicon chip and rinse it three times with absolute ethanol solution;

[0051] (5) After rinsing, the silicon wafer was blown dry with 0.5 MPa argon gas for the preparation of graphene.

Embodiment 3

[0053] The silicon chip surface treatment method that is used for graphene in-situ growth of the present embodiment specifically comprises the following steps:

[0054] (1) Take the (111) silicon wafer for growth, place it in deionized water for simple ultrasonic cleaning for 1 min, and then immerse it in dilute hydrofluoric acid with a volume ratio of 1:30 for 1 min;

[0055] (2) Take out the silicon wafer, rinse the surface with deionized water, and dry it with 1MPa argon;

[0056] (3) Immerse the silicon wafer in 0.2M resorcinol methanol solution for 30min;

[0057] (4) Take out the silicon chip and rinse it three times with absolute ethanol solution;

[0058] (5) After rinsing, the silicon wafer was blown dry with 1 MPa argon gas for the preparation of graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com