Noise analysis method in transformer substation

A method of analysis, technology of substations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

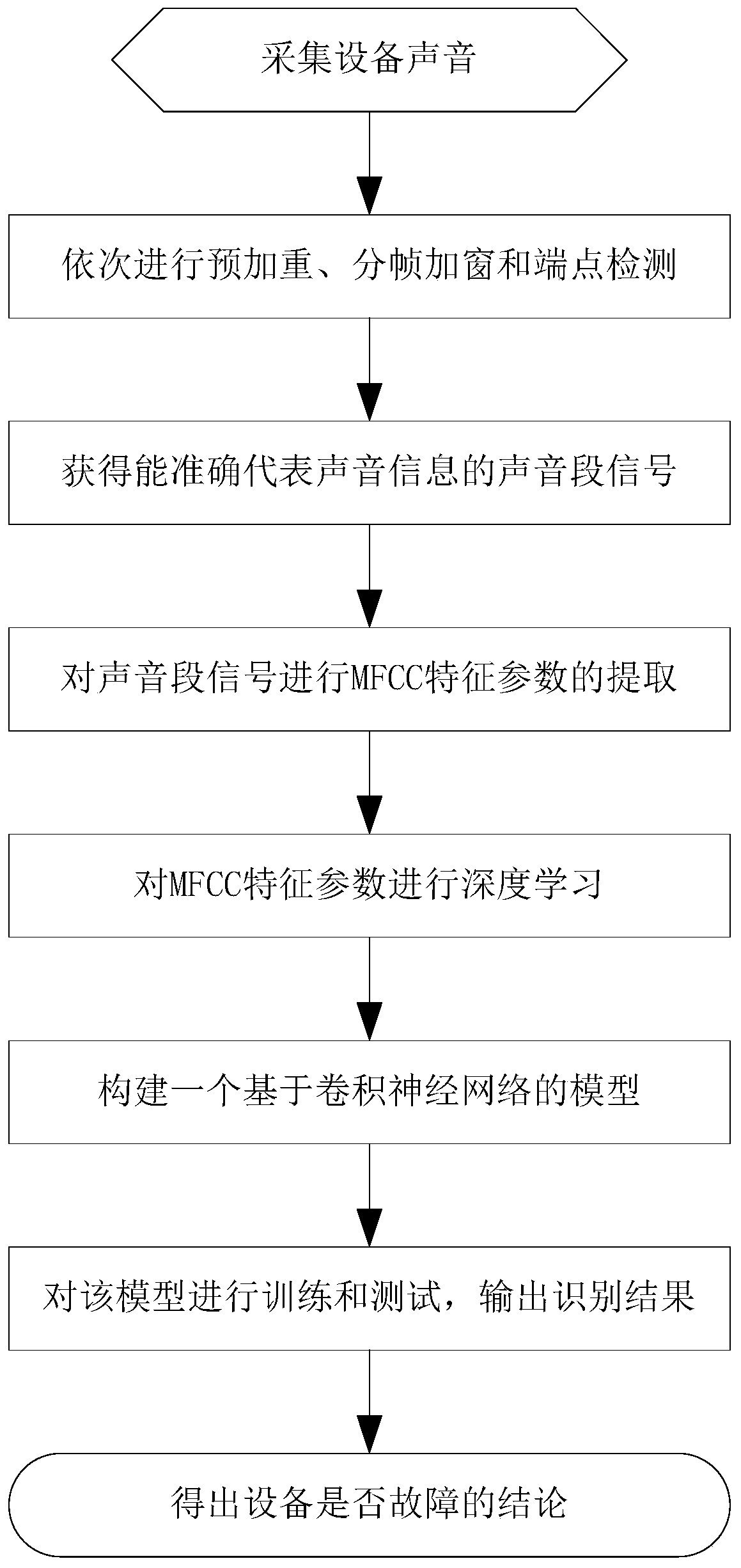

[0056] A noise analysis method in a substation provided by a preferred embodiment of the present invention, such as figure 1 shown, including the following steps:

[0057] Step 1: collect the sound of the device, perform preprocessing, and obtain a sound segment signal that can accurately represent the sound information and meet the system standards, and the preprocessing includes sequentially performing pre-emphasis, frame-by-frame windowing, and endpoint detection;

[0058] Step 1.1: Collect the sound sequences of different devices by carrying a microphone array;

[0059] Step 1.2: Since the sound collection will be affected by various aspects, and the high-frequency part will drop sharply in the dB range, so the first-order data filter is used to pre-emphasize the sound signal collected in step 1.1, and the The frequency spectrum of the falling part in the sound signal is improved, thereby maintaining the flatness of the signal frequency spectrum, ensuring that the frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com