Three-control timing board discharging control system

A board control and control box technology, used in conveyor control devices, manufacturing tools, conveyor objects, etc., can solve the problems of delaying the production line process, messing up the board, affecting the drying effect, etc., so as to avoid jamming and damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation mode of the present invention is illustrated by specific specific examples below, and those who are familiar with this technology can easily understand other advantages and effects of the present invention from the contents disclosed in this description. Obviously, the described embodiments are a part of the present invention. , but not all examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

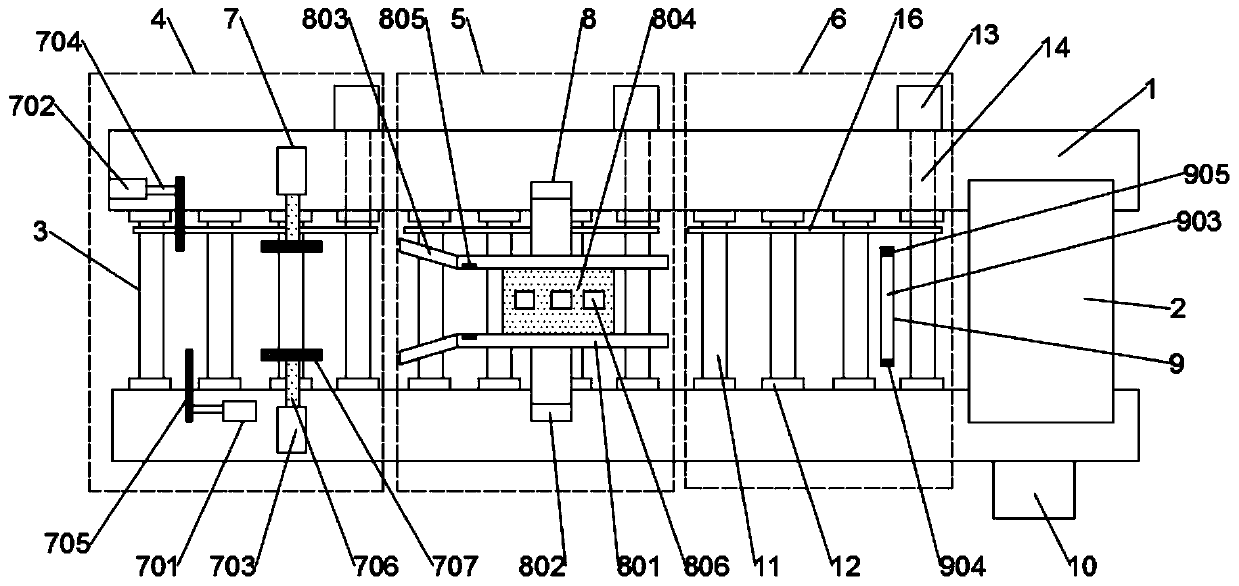

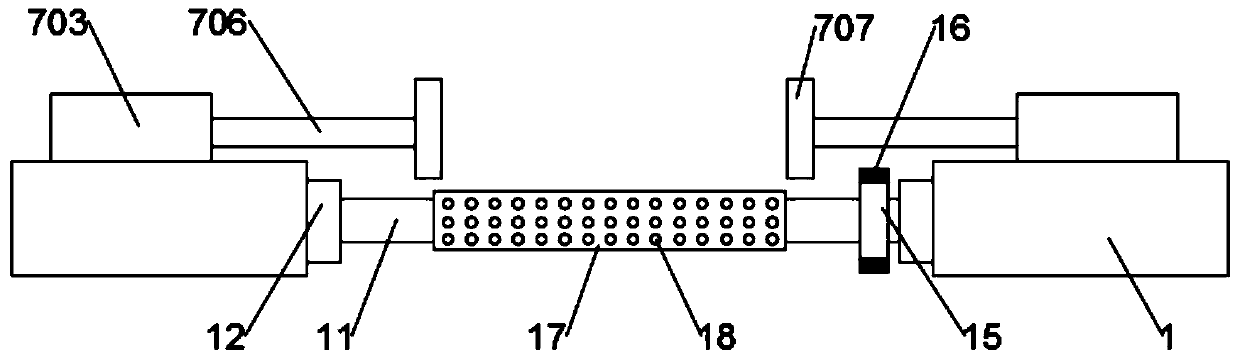

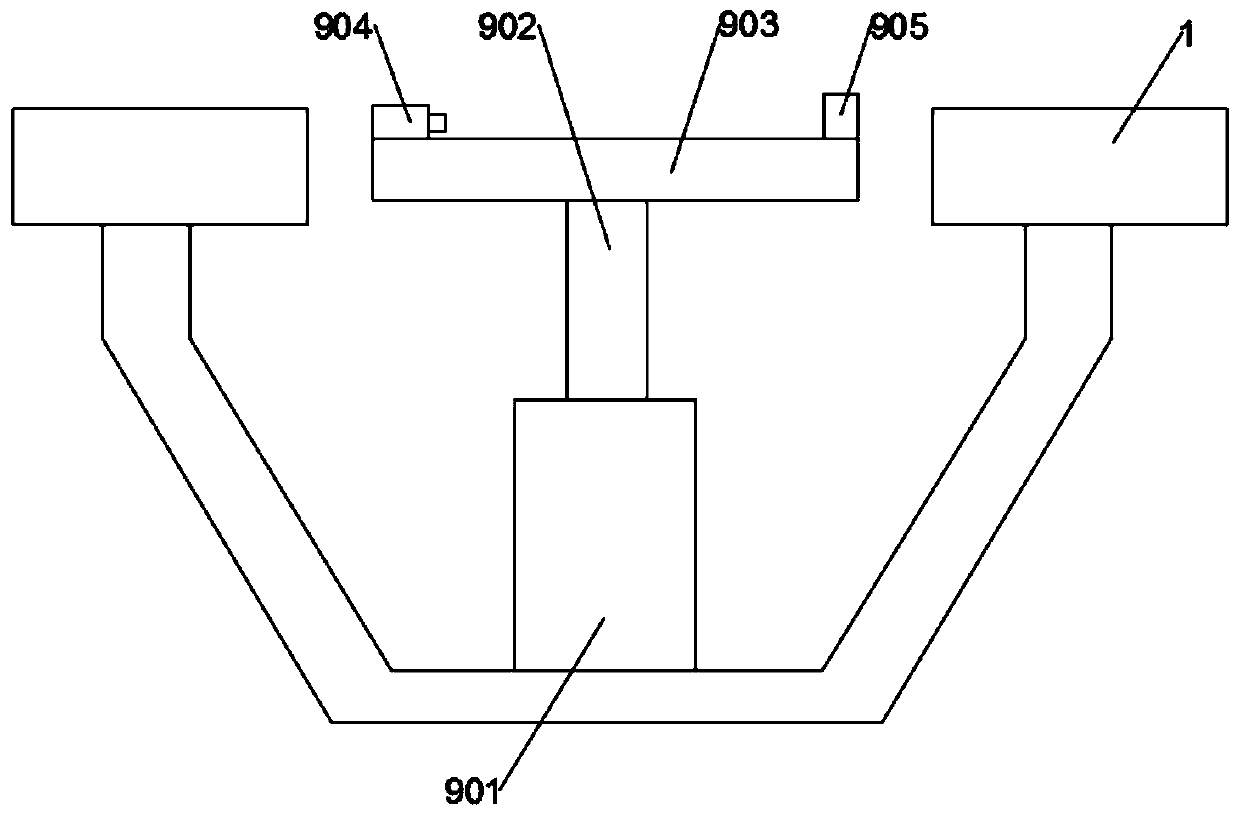

[0037] Such as Figure 1 to Figure 4 As shown, the present invention provides a three-control timing panel control system, including a work frame body 1, a dryer 2 for drying gypsum boards is installed on the top right side of the work frame body 1, and the top left side of the work frame body 1 There is a three-control accelerating roller table 3 for conveying the gypsum board to the dryer 2. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com