Variable-interaction mechanism and screen weaving equipment thereof

A technology of equipment and wire mesh, which is applied in the field of switching mechanism and its wire mesh weaving equipment, can solve the problems of single motion trajectory, complicated and complicated transmission mechanism, and poor transmission accuracy, so as to achieve reasonable structural relationship, ensure penetration quality, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

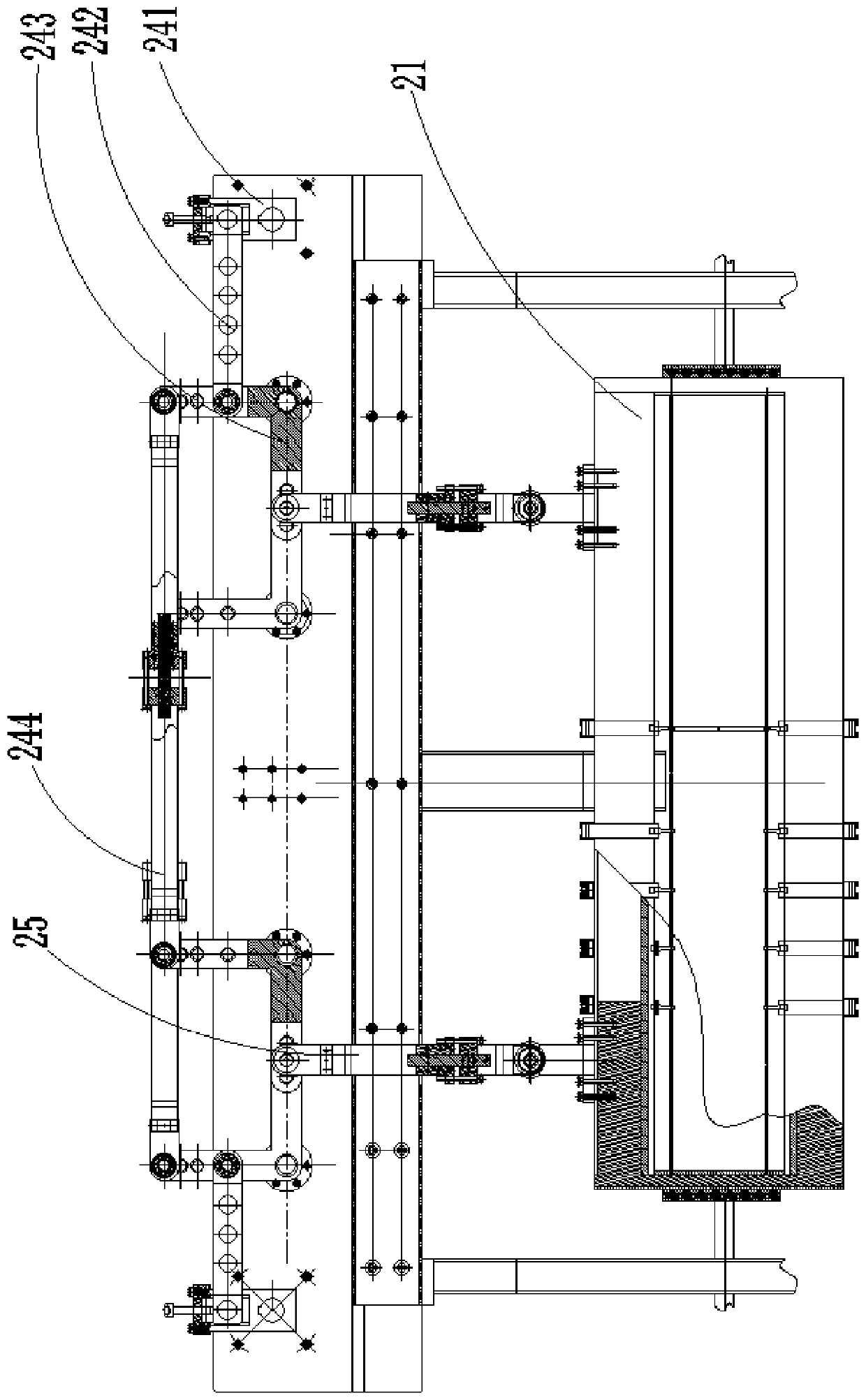

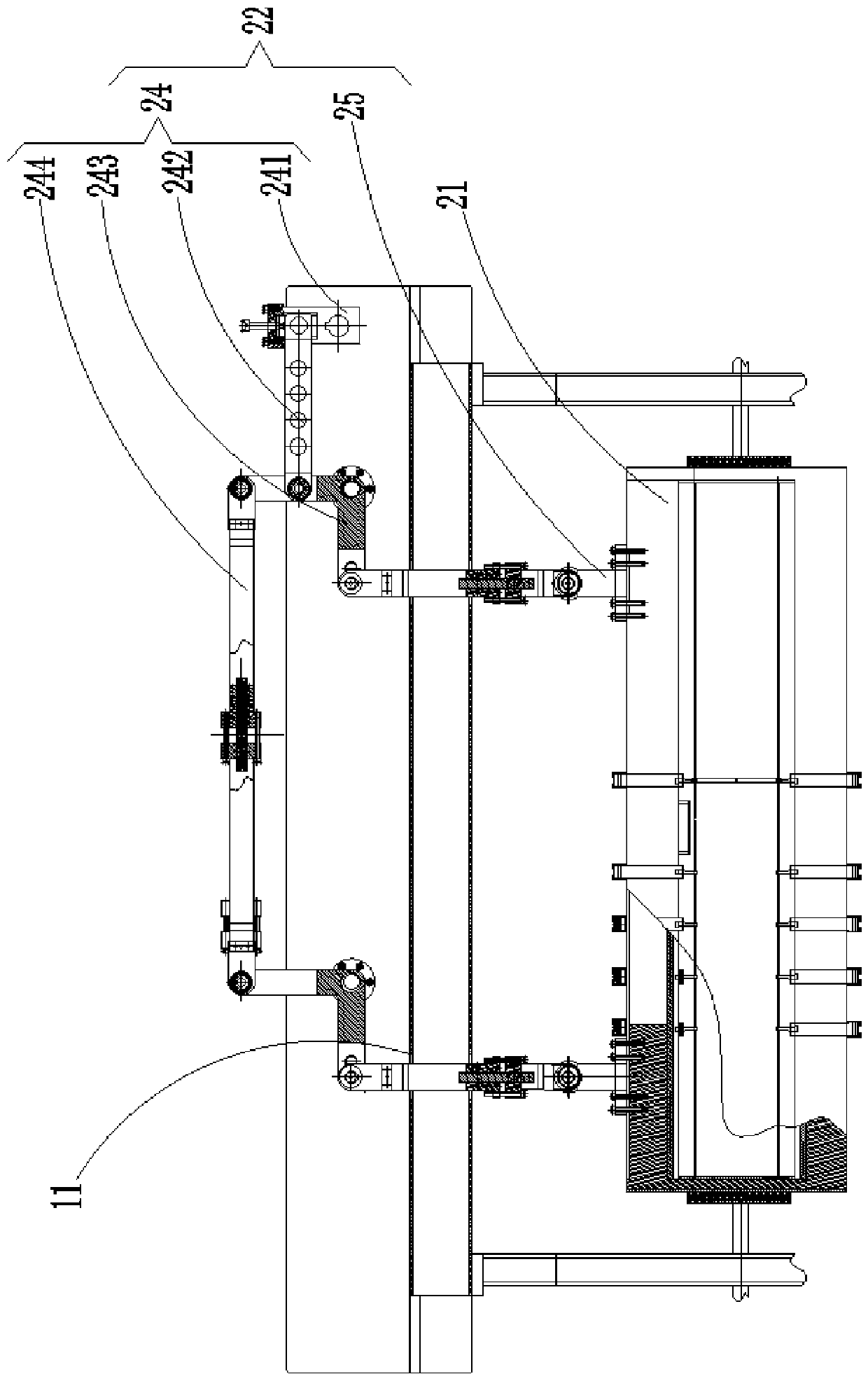

[0055] Please also refer to figure 2 and image 3 Now, a switching mechanism provided in Embodiment 1 of the present invention will be described. A switching mechanism includes a frame body 10 , a heald frame 21 and a driving assembly 22 . There are at least four sets of heald frames 21, and the four sets of heald frames 21 are arranged side by side. The lower ends of the heald frames 21 are used to drive the warp 70 from feeding; and connected with the heald frame 21, used to drive the connected heald frame 21 to do up and down interactive movement; and the supporting controller, the controller is set on the frame body 10; wherein, each heald frame 21 and each driving assembly 22 one by one Correspondingly, each group of driving components 22 is electrically connected to the controller.

[0056] The switching mechanism provided by the present invention works in the following way: four sets of driving components 22 are connected to four sets of heald frames 21 respectively...

Embodiment 2

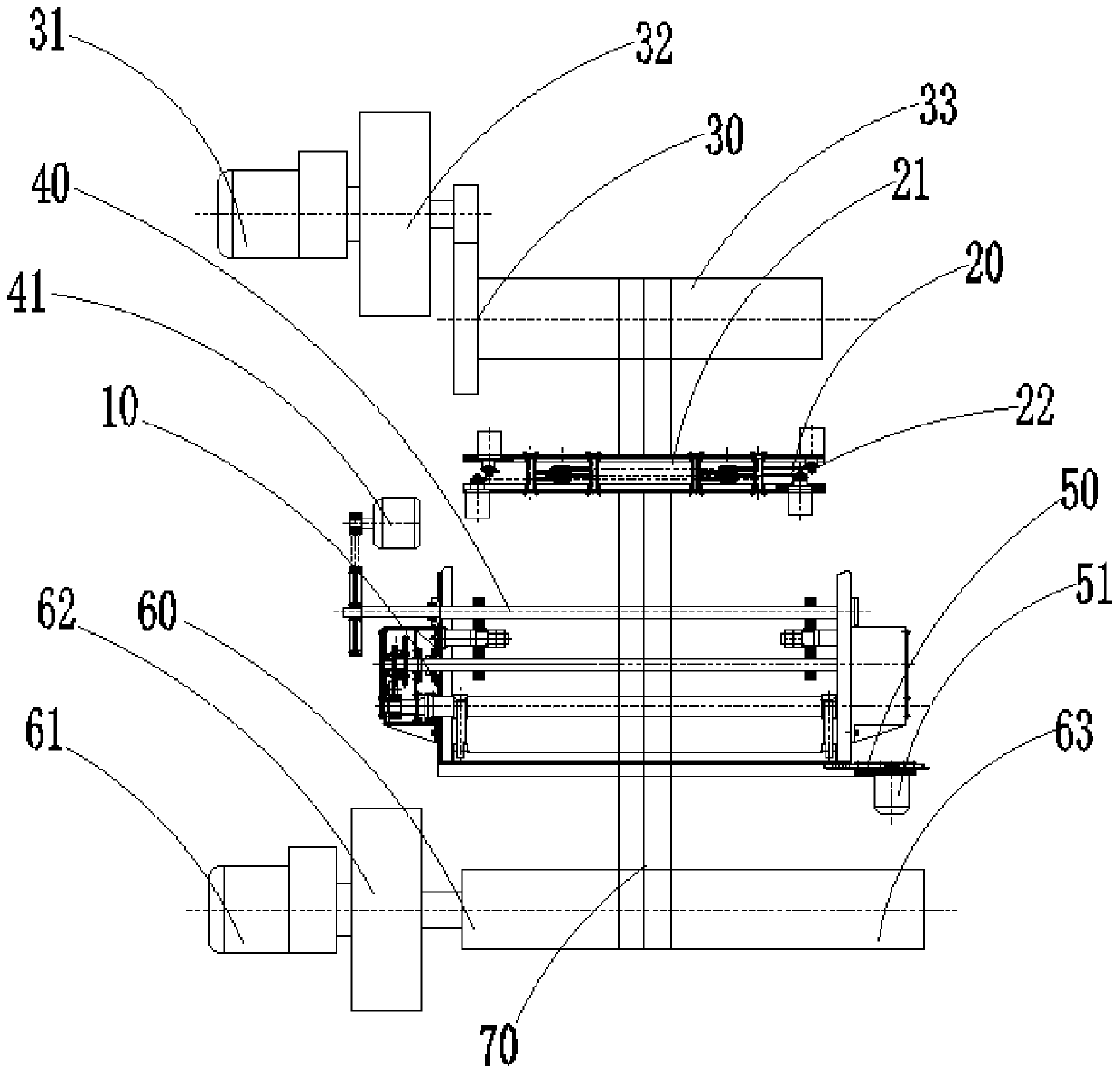

[0065] Please also refer to Figure 1 to Figure 6 As a second embodiment of the present invention, a screen weaving device is provided, which includes the transfer mechanism provided in the first embodiment, and also includes: a warp let-off mechanism 30, a sword-throwing weft insertion mechanism 50, a weft beating mechanism 40, and a roll Take mechanism 60. The warp let-off mechanism 30 is located at one end of the frame body 10 and is used for supplying the warp thread 70; the weft insertion mechanism 50 is located at the rear of the heald frame 21 and is arranged on one side of the frame body 10 for guiding the weft thread to pass through the heald thread. In the opening formed by the warp 70 of the frame 21; the beating-up mechanism 40 is arranged on the rear of the heald frame 21 along the feeding direction of the warp 70, and is opposite to the position of the weft insertion mechanism 50 for the weft insertion mechanism of the sword. 50 guides the weft thread that penet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com