Preparation method and application of CoOOH nanosheet modified Fe2O3 composite photo-anode

A technology of composite light and nanosheets, applied in electrodes, liquid chemical plating, coatings, etc., can solve the problems of complex experimental steps of photoanode materials and reduce the interface contact barrier, so as to promote the separation of photogenerated carriers and reduce the Water oxidation overpotential and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

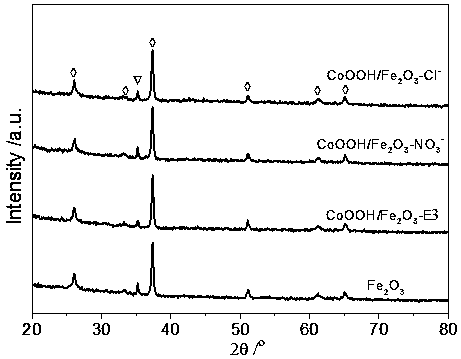

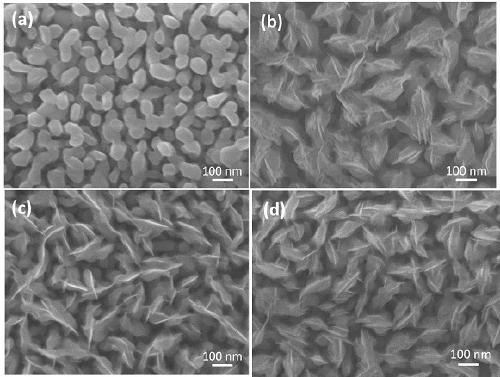

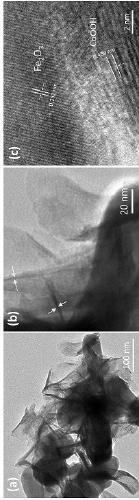

[0031] A CoOOH nanosheet modified Fe 2 o 3 The preparation method of composite light anode, it comprises the steps:

[0032] (a) Fe 2 o 3 Preparation of Electrode Sheets

[0033] Weigh 1.0812 g of FeCl 3 Put 0.5405 g of urea in a 100 mL beaker, add 50 mL of deionized water to dissolve it; then place the cleaned FTO substrate in the beaker, seal it and place the beaker in an oven at 100°C for 4 h; cool to room temperature, remove. Then it was washed with deionized water, dried at 80°C for 12 h; finally put into a muffle furnace for calcination at 500°C for 3 h, after cooling, it was annealed in a muffle furnace at 750°C for 15 min to obtain Fe 2 o 3 electrode sheet;

[0034] (b) CoOOH / Fe 2 o 3 Preparation of -E1 composite photoanode

[0035] Prepare 100 mL of 0.1 mol / L Co(NO 3 ) 2 solution, according to Co 2+ Add EDTA at a molar ratio of 1:1 to form 0.1 mol / L CoEDTA mixture. The previously prepared Fe 2 o 3 Electrodes were immersed in CoEDTA solution for 1 min ...

Embodiment 2

[0037] A CoOOH nanosheet modified Fe 2 o 3 The preparation method of composite light anode, it comprises the steps:

[0038] (a) Fe 2 o 3 Preparation of Electrode Sheets

[0039] Prepared according to the method and conditions of step (a) in Example 1;

[0040] (b) CoOOH / Fe 2 o 3 Preparation of -E2 composite photoanode

[0041] Prepared according to the method and conditions of step (b) in Example 1; the difference is that the number of times of dipping is 2 times.

Embodiment 3

[0043] A CoOOH nanosheet modified Fe 2 o 3 The preparation method of composite light anode, it comprises the steps:

[0044] (a) Fe 2 o 3 Preparation of Electrode Sheets

[0045] Prepared according to the method and conditions of step (a) in Example 1;

[0046] (b) CoOOH / Fe 2 o 3 Preparation of -E3 composite photoanode

[0047] Prepare according to the method and conditions of step (b) in Example 1; the difference is that the number of times of dipping is 4 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com