Heavy-gauge low-chromium ferritic stainless steel hot roller blind cover furnace annealing method

A stainless steel, thick gauge technology, applied in the field of ferritic stainless steel, can solve the problems of unrealizable welding process and limited application, and achieve the effect of reducing production labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples. For the experimental methods not indicating specific conditions in the following examples, follow conventional methods and conditions.

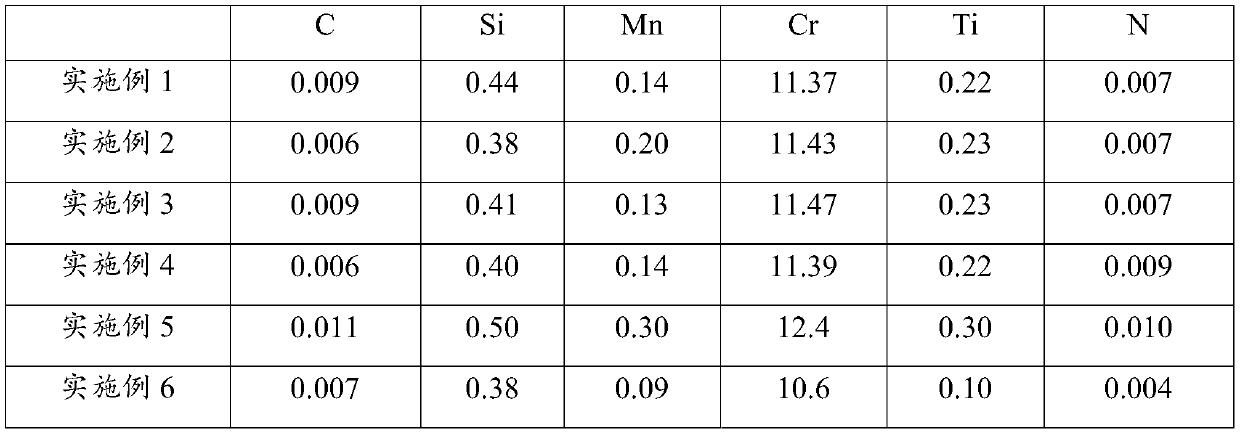

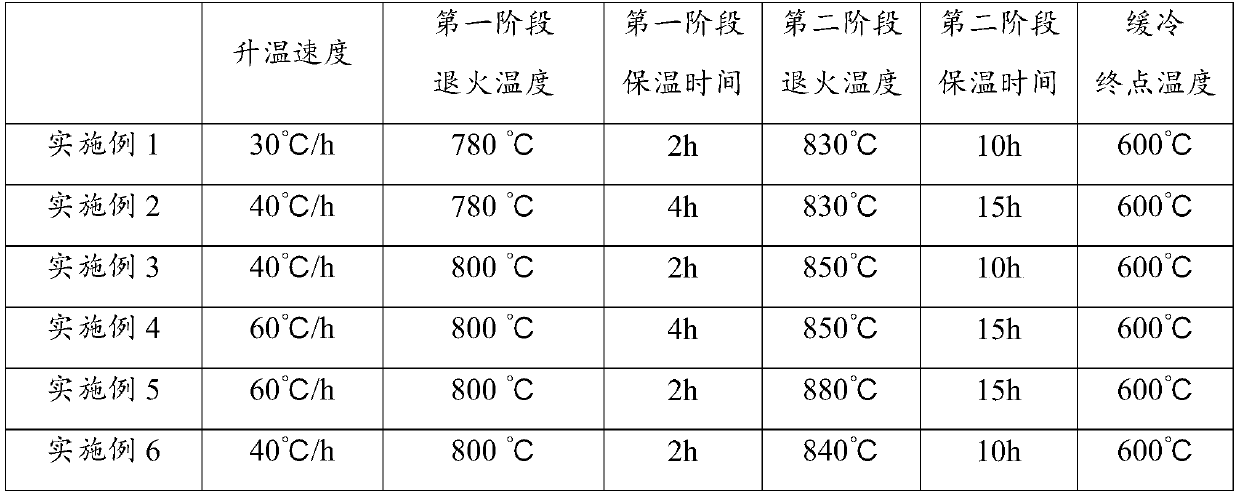

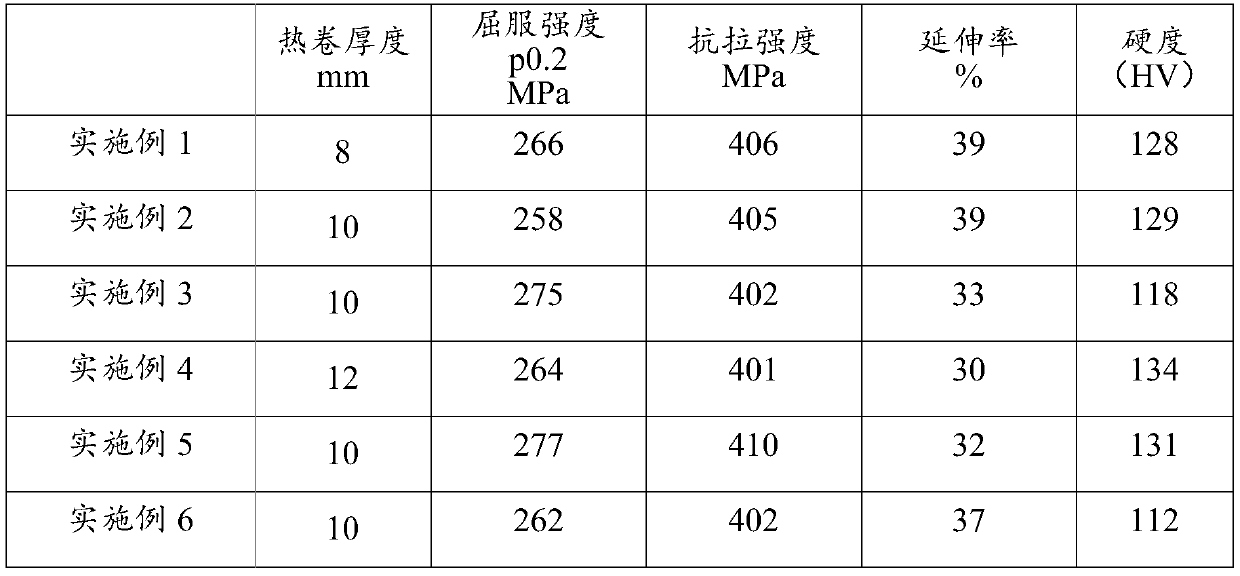

[0044] In the low-chromium ferritic stainless steels of Examples 1-6, except for iron and unavoidable elements, the content of each element is shown in Table 1. Among them, the technical parameters of the annealing method of the low-chromium ferritic stainless steel hot-rolled coils of Examples 1-6 using a full hydrogen gas bell furnace are shown in Table 2, and the mechanical properties of the corresponding low-chromium ferritic stainless steel products obtained are shown in Table 3 .

[0045] Table 1 Content of each element in low chromium ferritic stainless steel (%)

[0046]

[0047] The annealing technical parameter of table 2 embodiment 1-6

[0048]

[0049] Summary of the mechan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com