Water-based phase-change microcapsule film and preparation method thereof

A phase change microcapsule and microcapsule technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problem of poor film strength and weather resistance, weak phase change heat absorption and exothermic ability, and cannot be applied to industrial production, etc. problems, to achieve excellent thermal conductivity and thermal stability, suitable for large-scale production, simple and environmentally friendly production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

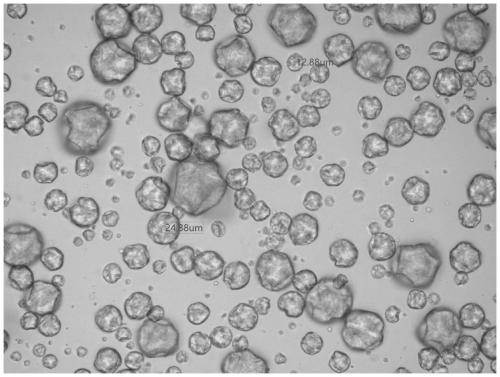

[0038] Weigh the paraffin in a beaker, heat and melt it in a constant temperature oven to a transparent liquid state, then add an appropriate amount of film material into the molten paraffin and stir to dissolve to form an oil phase; in another beaker, dissolve the emulsifier in ionized water to form a water phase. The oil phase and the water phase are then mixed, and a milky white O / W type emulsion is obtained by shearing. The phase change microcapsules are obtained by adding a crosslinking agent or an initiator to crosslink the film material to form a film.

[0039] After testing, the particle size of the obtained microcapsules is D50=20um, and the energy storage value of the obtained microcapsules is 217 J / g. According to the TGA experiment of thermogravimetric analysis, it has no obvious thermal weight loss before 250°C, and has good thermal stability.

Embodiment 1

[0041] Add 30g phase change microcapsule water dispersion slurry (solid content 36%) and 1g flame retardant to 6g adhesive (solid content about 50%), stir to make the phase change microcapsule evenly dispersed in the water phase; then add 0.15g of defoamer was stirred, and 0.15g of acrylate thickener was slowly added at the same time, and the stirring was continued for a period of time to obtain a uniform aqueous phase change microcapsule dispersion.

[0042] The aqueous phase change microcapsule dispersion liquid is uniformly coated into a film, dried in an oven, and cured to form an aqueous phase change microcapsule film.

[0043] After testing, the obtained milky white aqueous phase change microcapsule film has a thickness of 0.5 mm and a latent heat enthalpy of about 151 J / g. The flame retardant grade reaches UL-94HB grade.

Embodiment 2

[0045]Add 12g phase change microcapsule aqueous dispersion slurry (solid content 36%) and 0.7g flame retardant to 6g binder (solid content 50%), shake to fully wet the powder, stir to make the phase change microcapsules Disperse uniformly in the water phase; then add 0.1g defoamer, stir, and slowly add 0.1g carboxymethyl cellulose thickener at the same time, continue stirring for a period of time to obtain a uniform aqueous phase change microcapsule dispersion.

[0046] The aqueous phase change microcapsule dispersion liquid is uniformly coated into a film, dried in an oven, and cured to form an aqueous phase change microcapsule film.

[0047] After testing, the obtained milky white aqueous phase change microcapsule film has a thickness of 0.4 mm and a latent heat enthalpy of about 122 J / g. The flame retardant grade reaches UL-94HB grade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com