Friction power generation textile with moisture absorption and perspiration-discharging functions and preparation method thereof

A technology of moisture absorption and perspiration and friction power generation, which is applied in the direction of friction generators, chemical instruments and methods, and layered products, etc. No one studies, lack of wearing comfort and other issues, to achieve good wearing comfort, obvious gain effect, and ensure the effect of moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

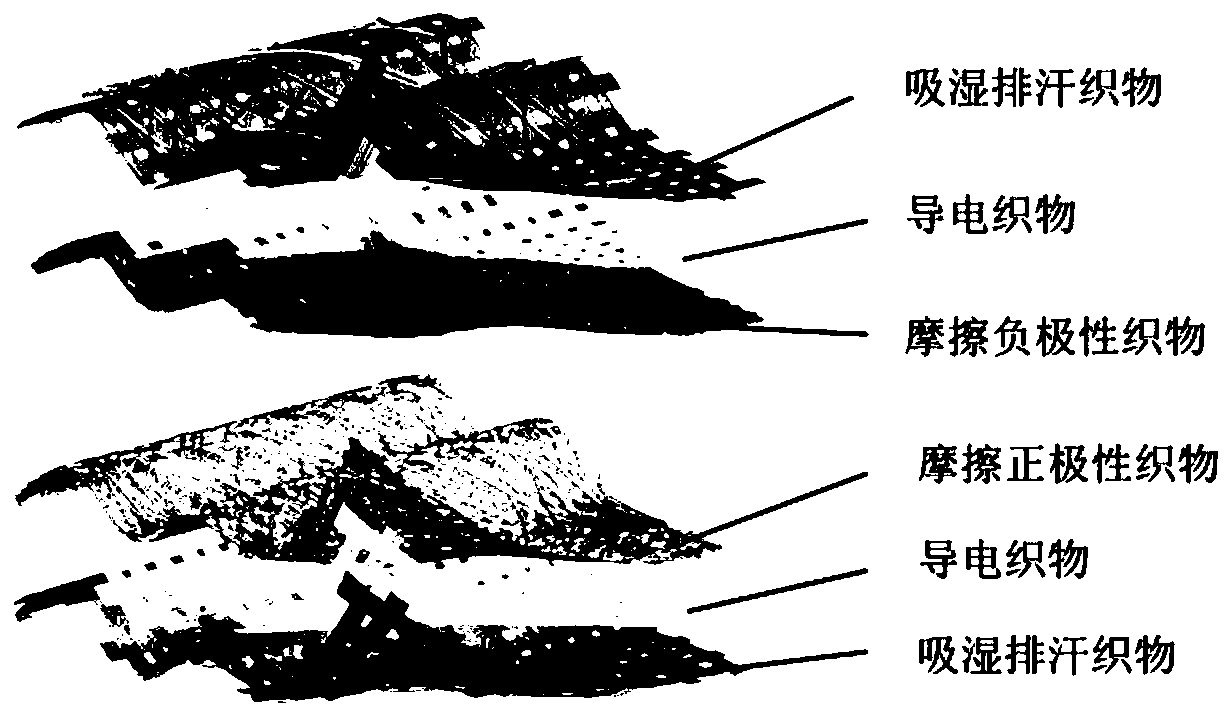

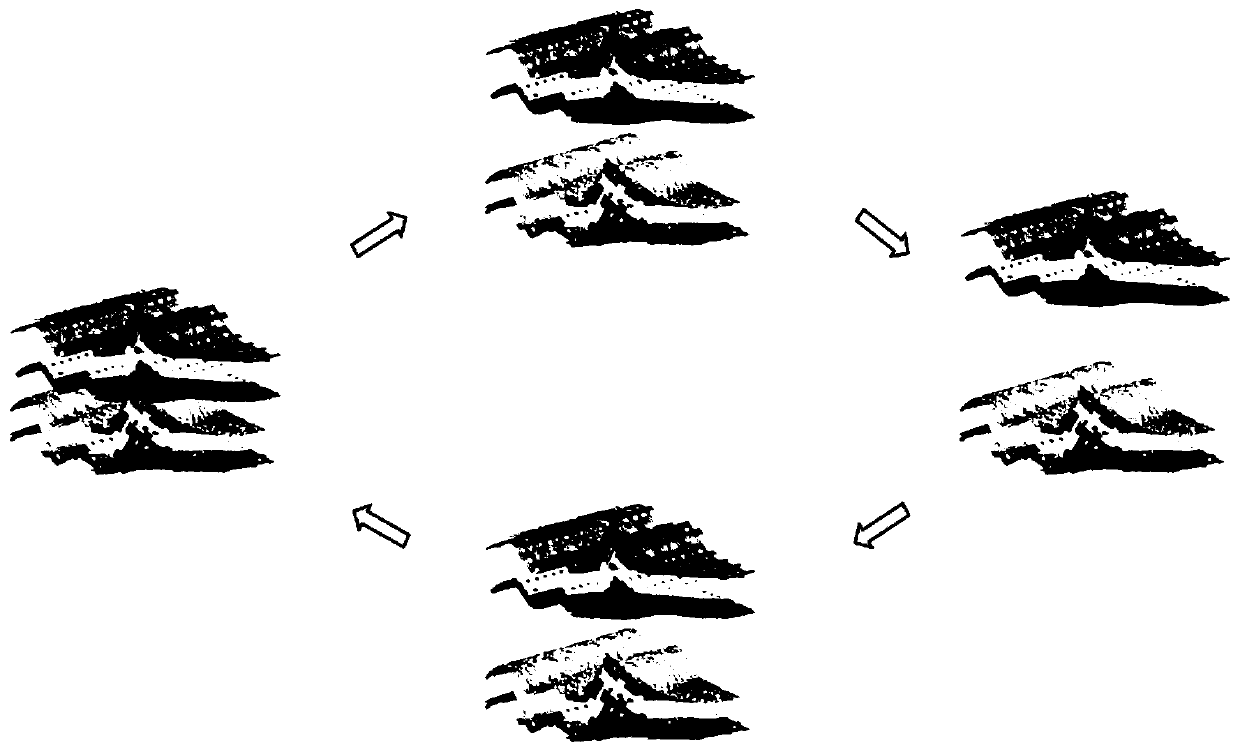

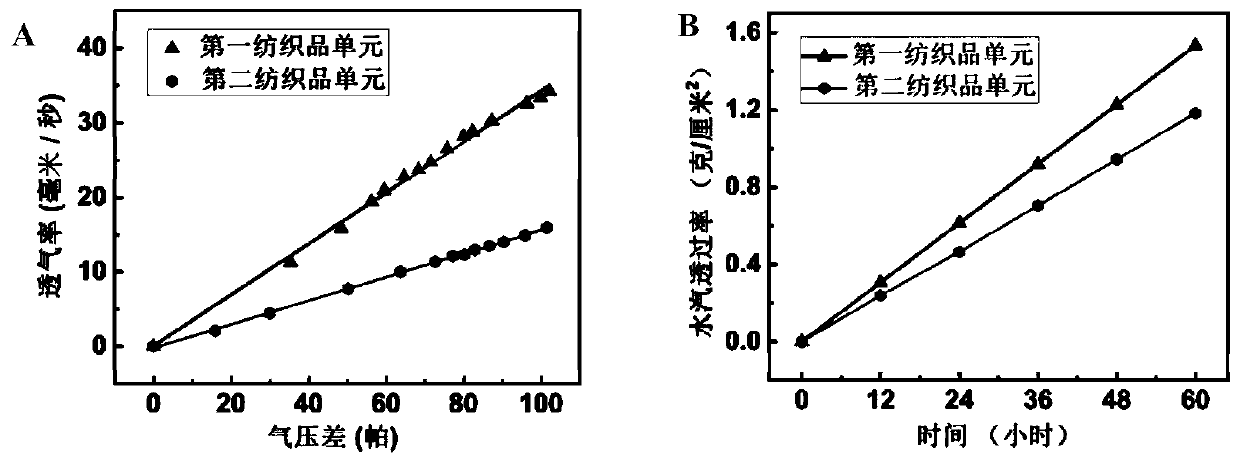

[0030] Two kinds of nanofiber networks, polyamide 6 and polyacrylonitrile, were deposited on the surface of breathable cotton fabric by electrospinning to obtain moisture absorption and perspiration fabric. The spinning parameters of polyamide 6 are: 12wt% spinning solution concentration (formic acid is used as solvent), the spinning voltage is 20kV, the spinning distance is 15cm, and the advancing speed is 0.2mL / h; the spinning parameters of polyacrylonitrile are : 6wt% spinning solution concentration (N,N-dimethylformamide as solvent), spinning voltage of 15kV, spinning distance of 15cm, and advancing speed of 0.5mL / h. Polytetrafluoroethylene fiber non-woven fabric and polyamide 6 fiber non-woven fabric were selected as friction negative and friction positive fabrics respectively. Moisture-wicking fabrics, conductive nickel-copper fabrics, and frictional polar fabrics were cut with scissors, each having a size of 4×6 cm. The three kinds of fabrics are superimposed one by on...

Embodiment 2

[0032] Two kinds of nanofiber networks, polyamide 6 and polyacrylonitrile, were deposited on the surface of breathable cotton fabric by electrospinning to obtain moisture absorption and perspiration fabric. The spinning parameters of polyamide 6 are: 20wt% spinning solution concentration (formic acid is used as solvent), the spinning voltage is 20kV, the spinning distance is 15cm, and the advancing speed is 0.2mL / h; the spinning parameters of polyacrylonitrile are : 16wt% spinning solution concentration (N,N-dimethylformamide as solvent), spinning voltage of 15kV, spinning distance of 15cm, and advancing speed of 0.5mL / h. Polyvinylidene fluoride non-woven fabrics and nylon non-woven fabrics were selected as friction negative and friction positive fabrics, respectively. Moisture-wicking fabrics, conductive nickel-copper fabrics, and frictional polar fabrics were cut with scissors, each having a size of 4×6 cm. The three kinds of fabrics are superimposed one by one, and the ele...

Embodiment 3

[0034]Two kinds of nanofiber networks, polyamide 6 and polyacrylonitrile, were deposited on the surface of breathable polyester fabric by electrospinning to obtain moisture absorption and perspiration fabric. The spinning parameters of polyamide 6 are: 20wt% spinning solution concentration (formic acid is used as solvent), the spinning voltage is 20kV, the spinning distance is 15cm, and the advancing speed is 0.2mL / h; the spinning parameters of polyacrylonitrile are : 16wt% spinning solution concentration (N,N-dimethylformamide as solvent), spinning voltage of 15kV, spinning distance of 15cm, and advancing speed of 0.5mL / h. Polytetrafluoroethylene non-woven fabrics and polylactic acid non-woven fabrics were selected as friction negative and friction positive fabrics, respectively. Moisture-wicking fabrics, conductive carbon cloths, and frictional polar fabrics were all cut with scissors in a size of 4×6 cm. The three kinds of fabrics are superimposed one by one, and the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com