Resistance-free electric spark pulsed power source and processing method and gap discharge state recognition state thereof

A pulse power supply, non-resistance technology, applied in the field of non-resistance EDM pulse power supply and its processing and gap discharge state identification, can solve the problem of not knowing the gap discharge status, etc., achieve high bandwidth and real-time performance, simple structure, flexible control reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

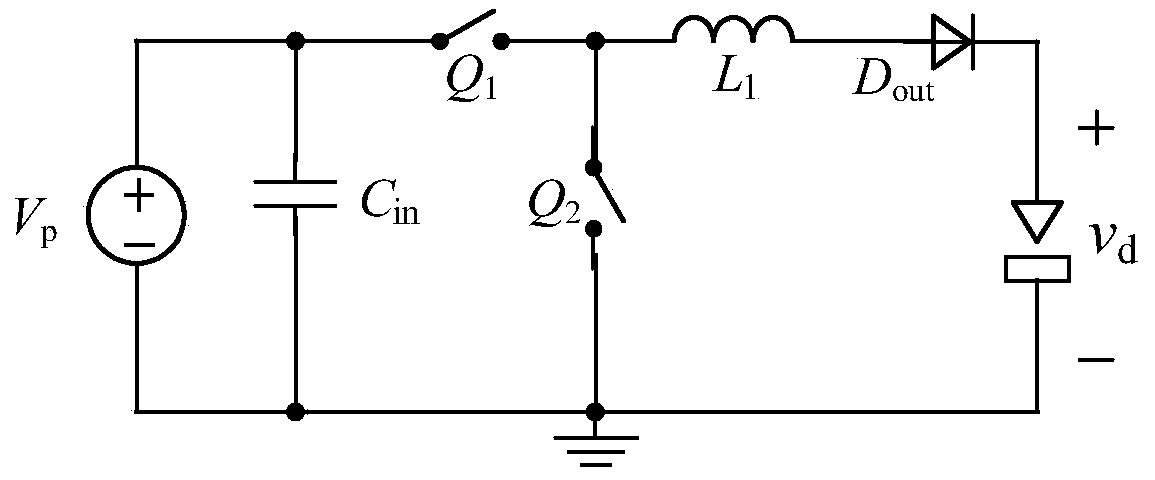

[0032] Such as figure 1 As shown, the non-resistance type medium-travel pulse power supply includes a power loop, a drive circuit, a field programmable gate array FPGA controller, a voltage detection circuit and a current detection circuit. Among them, the power circuit is responsible for providing the gap with breakdown voltage and discharge energy after breakdown; the voltage detection circuit and current detection circuit detect the voltage and current of the load (gap) in real time, and the signal is filtered and conditioned to obtain an analog signal, and the analog signal passes through the analog The digital signal is obtained by digital conversion, and finally sent to the FPGA controller; the FPGA controller outputs the PWM control signal to the drive circuit according to the obtained current and voltage detection signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com