A processing method for flaring and forming stainless steel small-diameter thin-walled pipe fittings

A processing method and small diameter technology, which are applied in the field of flaring and forming of stainless steel small diameter thin-walled pipe fittings, can solve the problems of cracks, low product qualification rate, complex spatial structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

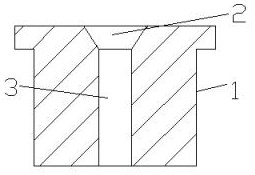

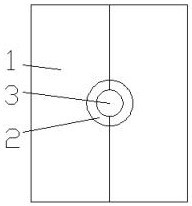

[0038] Example 1. A processing method for flaring and forming stainless steel small-diameter thin-walled pipe fittings, which consists of Figure 1-4 As shown, a stainless steel small-diameter thin-walled pipe is flared to a taper of 74°±0.5°;

[0039] A stainless steel small-diameter thin-walled pipe fitting made of 1Cr18Ni9Ti is an aviation oil pipe fitting. The outer diameter of the pipe fitting is φ8, the inner diameter is φ6, and the wall thickness of the pipe fitting is only 1mm. .

[0040] The processing method for flaring the stainless steel small-diameter thin-walled pipe fittings includes the following steps:

[0041] a. Cut the end face of the pipe fitting flat, and the cutting surface of the pipe fitting is at a right angle of 90°±0.2° to the axis of the pipe fitting, and the product A is obtained;

[0042] b. Carry out solid-melting treatment on the pipe fittings of product A, the temperature of solid-melting treatment is 280°C, the holding time is 4 hours, and...

Embodiment 2

[0048] Example 2. A processing method for flaring and forming stainless steel small-diameter thin-walled pipe fittings, which consists of Figure 1-4 As shown, a stainless steel small-diameter thin-walled pipe is flared to a taper of 74°±0.5°;

[0049] A stainless steel small-diameter thin-walled pipe fitting made of 1Cr18Ni9Ti is an aviation oil pipe fitting. The outer diameter of the pipe fitting is φ4, the inner diameter is φ3, and the wall thickness of the pipe fitting is only 0.5mm. 12mm.

[0050] The processing method for flaring the stainless steel small-diameter thin-walled pipe fittings includes the following steps:

[0051] a. Cut the end face of the pipe fitting flat, and the cutting surface of the pipe fitting is at a right angle of 90°±0.2° to the axis of the pipe fitting, and the product A is obtained;

[0052] b. Carry out solid-melting treatment on the pipe fittings of product A, the temperature of solid-melting treatment is 250°C, the holding time is 3.5h, ...

Embodiment 3

[0058] Example 3. A processing method for flaring and forming stainless steel small-diameter thin-walled pipe fittings, which consists of Figure 1-4 As shown, a stainless steel small-diameter thin-walled pipe is flared to a taper of 74°±0.5°;

[0059] A stainless steel small-diameter thin-walled pipe fitting made of 1Cr18Ni9Ti is an aviation oil pipe fitting. The outer diameter of the pipe fitting is φ12, the inner diameter is φ10, and the wall thickness of the pipe fitting is only 1mm. .

[0060] The processing method for flaring the stainless steel small-diameter thin-walled pipe fittings includes the following steps:

[0061] a. Cut the end face of the pipe fitting flat, and the cutting surface of the pipe fitting is at a right angle of 90°±0.2° to the axis of the pipe fitting, and the product A is obtained;

[0062] b. Carry out solid-melting treatment to the pipe fittings of product A, the temperature of the solid-melting treatment is 300°C, the holding time is 4.5h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com