Dentin collagen fiber demineralization material and preparation method and application thereof

A collagen fiber and dentin technology, applied in dental preparations, dentistry, dental prosthesis, etc., can solve the problems of dentin collagen degradation and high incidence of secondary caries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

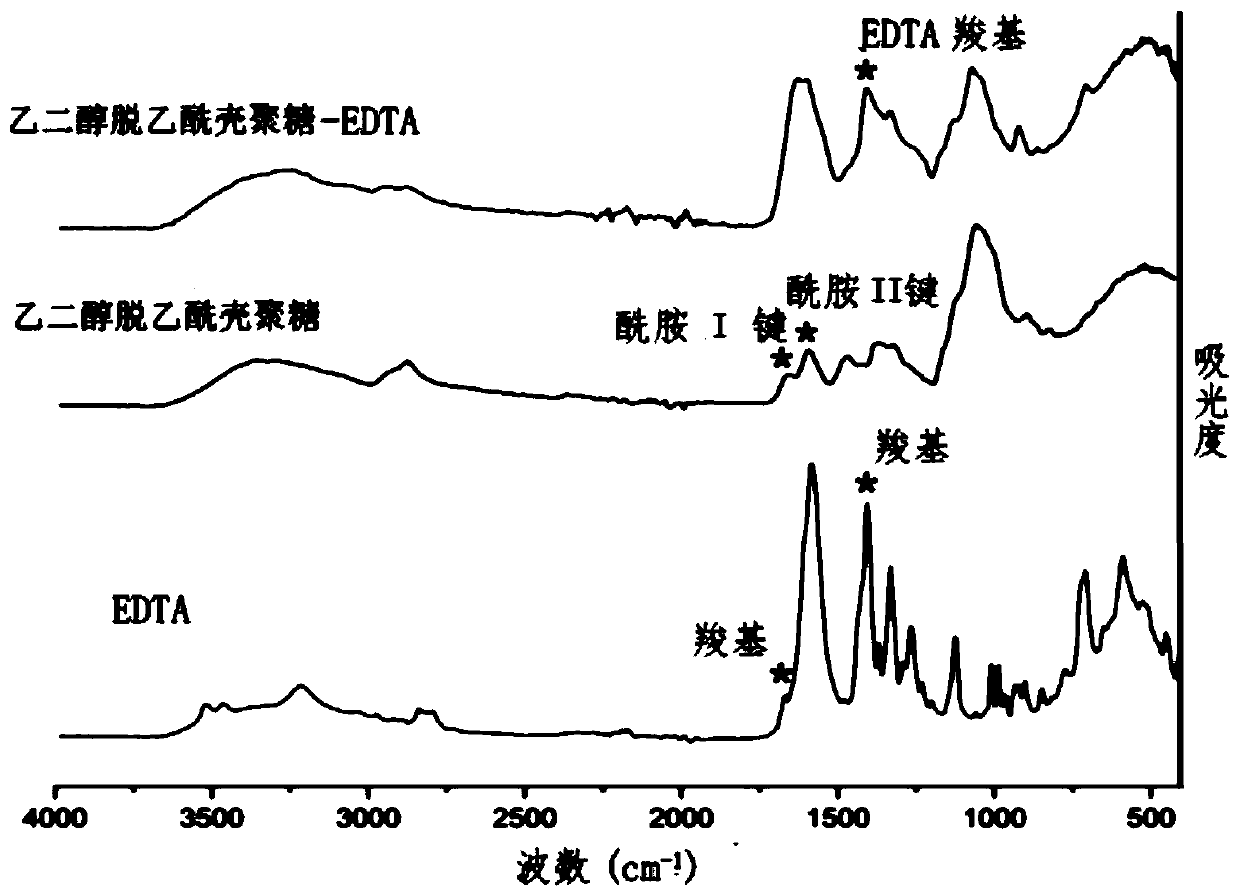

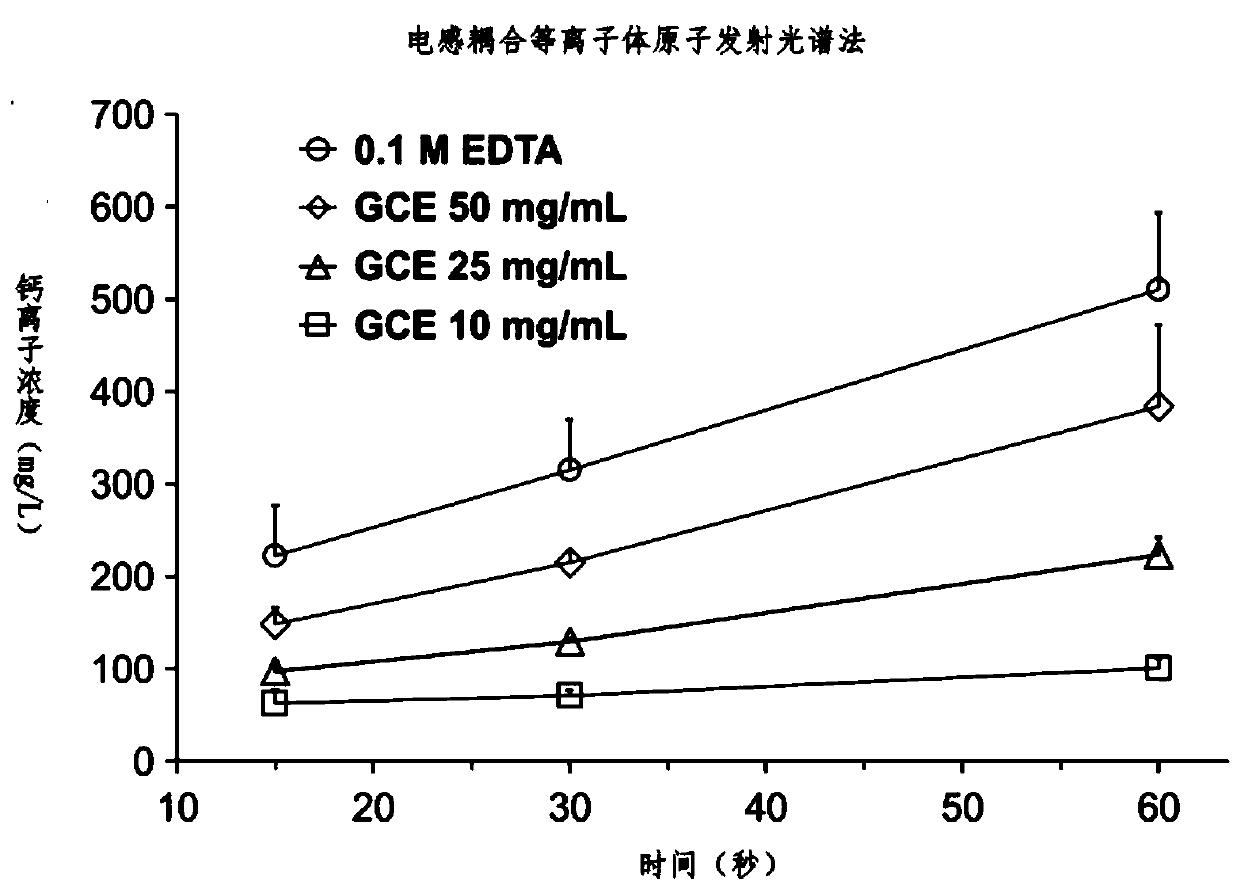

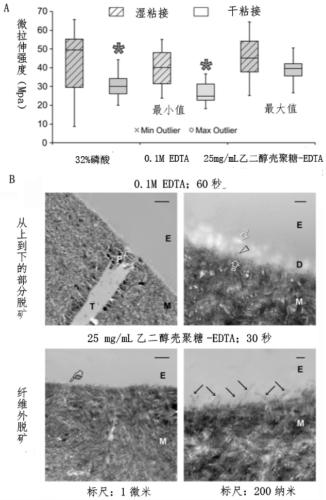

[0065] The material of this embodiment is to adopt the ethylene glycol chitosan (polymerization degree ≥ 400, MilliporeSigma, St.Louis, MO, USA) aqueous solution of suitable concentration to mix with EDTA aqueous solution, add 1-ethyl-3-( After the 3-dimethylaminopropyl)-carbodiimide cross-linking agent was continuously stirred at room temperature for 14 hours, unreacted residues were removed using appropriate dialysis conditions. Wherein the total amount of ethylene glycol chitosan is 10 g, EDTA 300 g, and 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide cross-linking agent 15 g.

[0066] For example, a preferred dialysis condition is that the above reaction solution is dialyzed in a dialysis membrane with a molecular weight cut-off of 12-14 kDa and containing 0.05M NaOH to remove reactants with smaller molecular weights, and again with a molecular weight cut-off of 12-14 kDa and containing Dialyze against a dialysis membrane against double distilled water to remove uncrosslink...

Embodiment 2

[0069] This embodiment is different from embodiment 1 in that:

[0070] (1) ethylene glycol chitosan is dissolved in deionized water to form a chitosan solution with a concentration of 10 mg / mL;

[0071] (2) EDTA is dissolved in deionized water to form a concentration of EDTA aqueous solution of 300mg / mL;

[0072] (3) The above two solutions are mixed in equal volumes, and the pH of the mixed solution is adjusted to 6.0;

[0073] (4) Dissolve 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide crosslinking agent in the above mixture at a concentration of 15 mg / mL to make the carboxyl group on the EDTA molecular chain functional The group is covalently bonded to the amine functional group on the soluble chitosan skeleton, and is continuously stirred at room temperature for 14 hours;

[0074] (5) Place the above reaction solution in a dialysis membrane with a molecular weight cut-off of 12-14kDa and contain 0.05M NaOH for dialysis to remove reactants with a smaller molecular weight...

Embodiment 3

[0086] This embodiment differs from embodiment 2 in that:

[0087] (1) Carboxymethyl chitosan was dissolved in deionized water to form a chitosan solution with a concentration of 7 mg / mL.

[0088] (2) EDTA is dissolved in deionized water to form a concentration of 200mg / mL EDTA aqueous solution, the EDTA aqueous solution is mixed with carboxymethyl chitosan solution in equal volumes, and the pH of the mixed solution is adjusted to 6.0; the 1-ethyl-3 -(3-Dimethylaminopropyl)-carbodiimide cross-linking agent was dissolved in the above mixture at a concentration of 13 mg / mL, and kept stirring at room temperature for 12 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com