Cylinder head cover with cooling function

A cylinder head cover and function technology, applied in the direction of engine components, machines/engines, casings, etc., can solve the problems of engine cooling, lubrication effects, weakened ability of oil mist condensation, and reduced oil volume, etc., to improve the condensation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

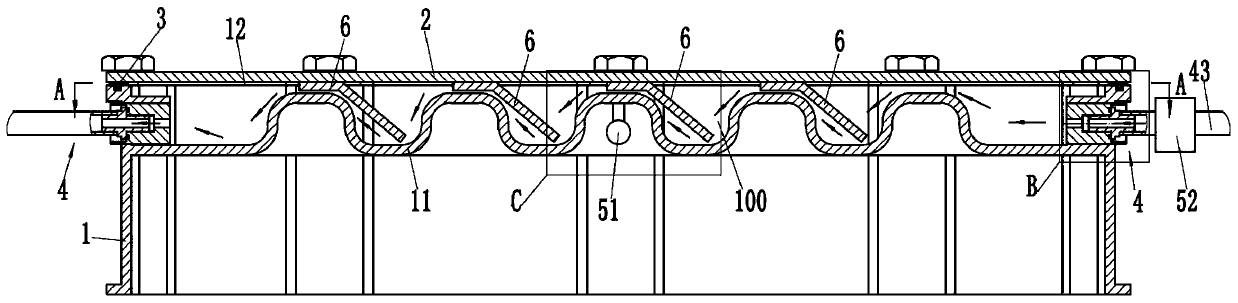

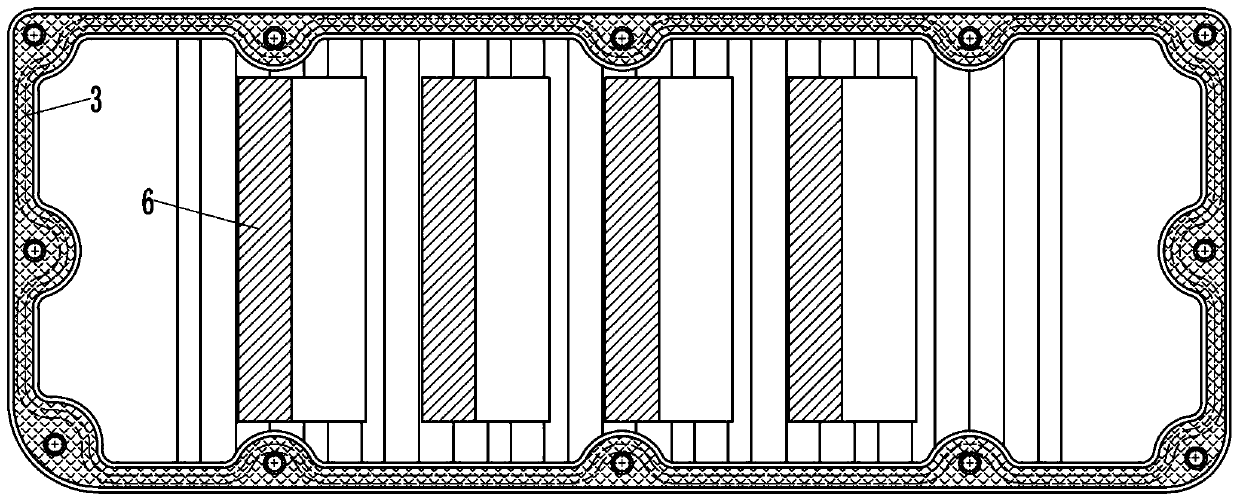

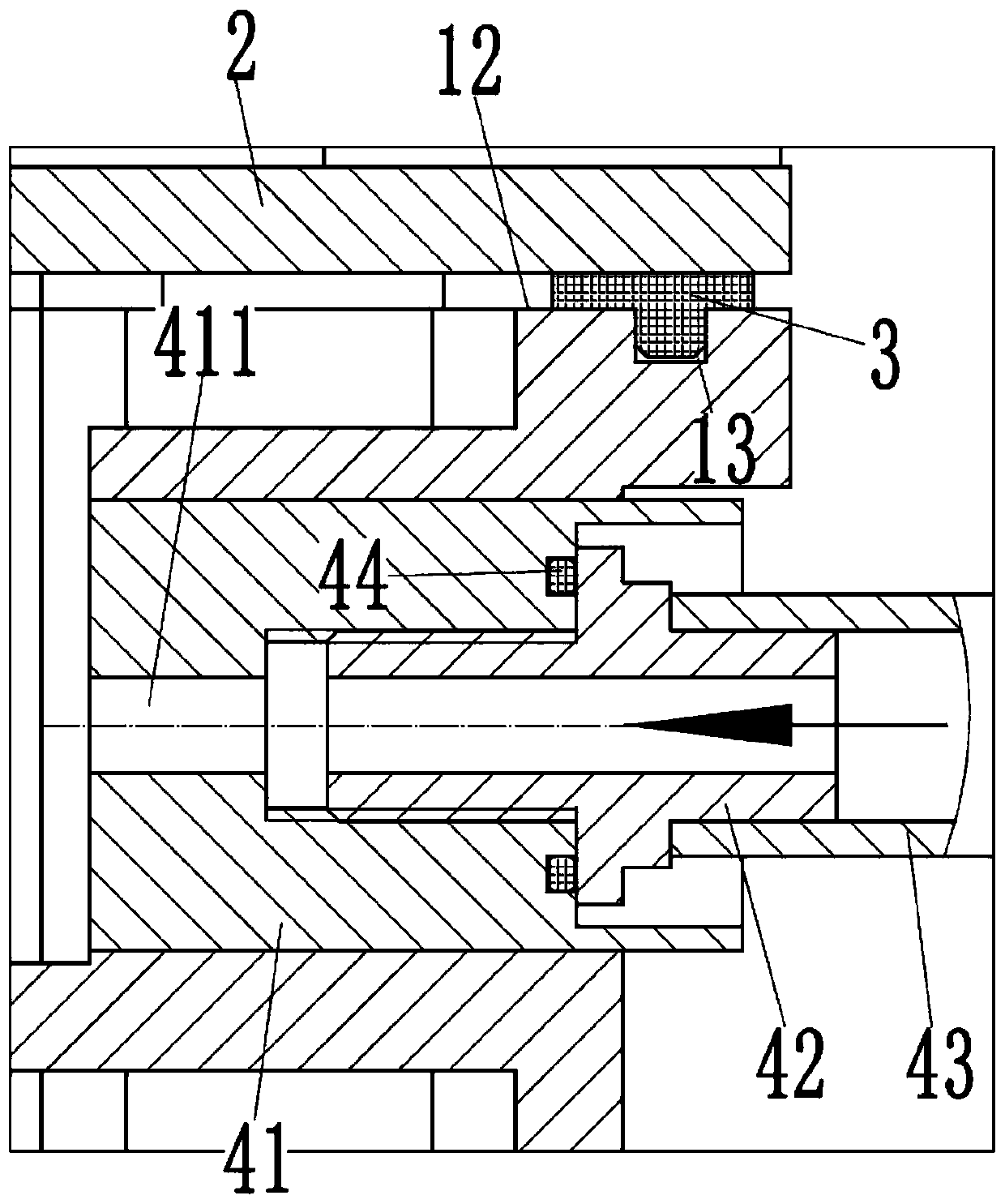

[0018] Examples, see e.g. Figure 1 to Figure 5 As shown, a cylinder head cover with cooling function includes a cylinder head cover 1, a corrugated upper side wall 11 is formed on the upper end of the cylinder head cover 1, and a sealing cover plate 2 is arranged above the upper side wall 11, The sealing cover plate 2 is fixed on the upper end plane 12 of the cylinder head cover 1 by a plurality of bolts, the upper end plane 12 is higher than the peak end of the upper side wall 11, and the sealing cover plate 2 and the upper end plane 12 are clamped There is a gasket 3, the upper part of the cylinder head cover 1, the sealing cover plate 2 and the gasket 3 form a cooling chamber 100; two ends of the cylinder head cover 1 are respectively connected with a cooling liquid pipe communicating with the cooling chamber 100 Assemblies 4, two coolant pipe assemblies 4 are provided with one in and one out.

[0019] Furthermore, the cross-section of the sealing pad 3 is in the shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com