Pyrolytic process and device capable of directly transforming straws into petrol and diesel

A direct and pyrolysis technology, applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, special forms of dry distillation, etc., can solve the problems of inability to directly use internal combustion engines and various transportation vehicles, low calorific value of bio-oil, easy polymerization and coking, etc. To achieve the effect of increasing the pyrolysis rate and production capacity, reducing the pyrolysis temperature, and increasing the content of hydrocarbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

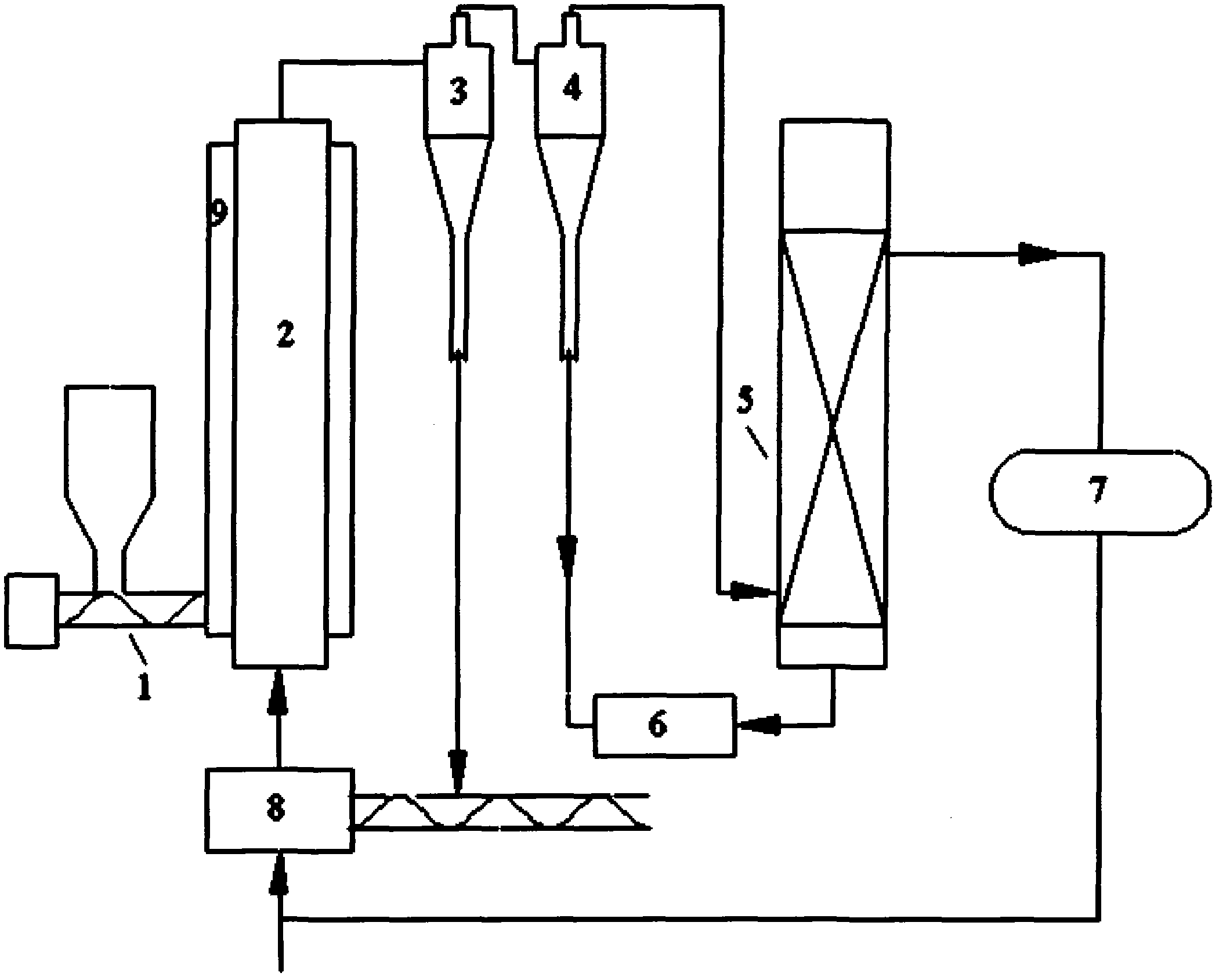

Embodiment 1

[0033] The crop stalks are dried by a drum dryer so that the moisture content of the crop stalks is 0.05wt%, and the crop stalks are crushed into particles with a particle size of 10 mesh with a hammer crusher, and then mixed with 7wt% of waste plastics and 0.1wt% of Pt / SiO 2 -Ni catalysts are mixed and input into the pyrolysis reactor 2. Start the stirrer at a speed of 2r / min. Diesel oil was burned in the burner 8, and the pyrolysis reactor was heated for 15 minutes. The supply of diesel oil to the burner 8 is stopped, and the by-products (biomass charcoal powder and non-condensable combustible gas) of crop straw pyrolysis are introduced into the burner 8 to burn to supply pyrolysis heat. The crop straw is thermally decomposed into pyrolysis steam, biochar powder and non-condensable combustible gas in the pyrolysis reactor 2, and the voltage regulator 9 and the feedforward control system are adjusted to control the vacuum degree of the pyrolysis reactor 2 at 60kpa. The te...

Embodiment 2

[0035] The crop stalks are dried by a drum dryer so that the moisture content of the crop stalks is 0.02wt%, and the crop stalks are crushed into 8-mesh particles with a hammer crusher, and then mixed with 10wt% waste plastics and 0.2wt% SiO 2 -Fe 2 o 3 The catalysts are mixed and input into the pyrolysis reactor 2. Start the stirrer at a speed of 3r / min. Diesel oil was burned in the burner 8, and the pyrolysis reactor was heated for 220 minutes. The supply of diesel oil to the burner 8 is stopped, and the by-products (biomass charcoal powder and non-condensable combustible gas) of crop straw pyrolysis are introduced into the burner 8 to burn to supply pyrolysis heat. The crop straw is thermally decomposed into pyrolysis steam, biochar powder and non-condensable combustible gas in the pyrolysis reactor 2, and the voltage regulator 9 and the feedforward control system are adjusted to control the vacuum degree of the pyrolysis reactor 2 at 70kpa. The temperature is controlle...

Embodiment 3

[0037] The crop stalks are dried by a drum dryer so that the moisture content of the crop stalks is 0.03wt%, and the crop stalks are broken into particles with a particle size of 15 mesh with a hammer crusher, and then mixed with 15wt% waste plastics, 0.5wt% Fe / SiO 2 -MgO catalysts are mixed and input into the pyrolysis reactor 2. Start the stirrer at a speed of 4r / min. Diesel oil was burned in the burner 8, and the pyrolysis reactor was heated for 220 minutes. The supply of diesel oil to the burner 8 is stopped, and the by-products (biomass charcoal powder and non-condensable combustible gas) of crop straw pyrolysis are introduced into the burner 8 to burn to supply pyrolysis heat. The crop straw is thermally decomposed into pyrolysis steam, biochar powder and non-condensable combustible gas in the pyrolysis reactor 2, and the voltage regulator 9 and the feedforward control system are adjusted to control the vacuum degree of the pyrolysis reactor 2 at 80kpa. The temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com