Prefabricated column-prefabricated beam connection structure based on phosphorus-magnesium material and construction method

A technology for connecting structures and construction methods, which is applied in the direction of building structure and construction, can solve the problems of long curing time of post-cast concrete, reduce the turnover frequency of formwork and support system, and reduce the progress of the project, so as to achieve the guarantee of grouting density, Ensuring compactness and improving turnover frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

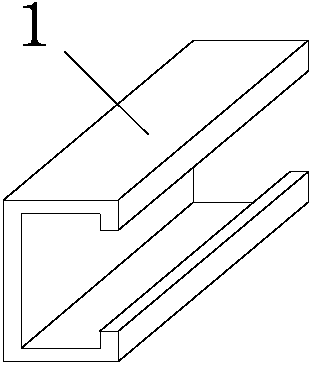

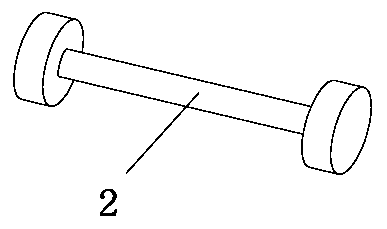

[0043] A connection structure of prefabricated columns and beams based on phosphorus and magnesium materials, consisting of C-shaped steel slots 1, connecting steel bars 2 with anchor heads, prefabricated columns 4, and prefabricated beams 5; the C-shaped steel slots are pre-embedded in prefabricated columns 4 , In the prefabricated beam 5; the two ends of the connecting steel bars 2 with anchor heads are inserted into the C-shaped steel slot 1 respectively; the C-shaped steel slot 1 is filled with phosphorus and magnesium grouting material 3;

[0044] The C-shaped steel slot 1 is made of steel material and is in the shape of a long strip with a C-shaped cross section. The back of the C-shaped steel slot 1 is welded to the steel anchor plate 6 embedded in the prefabricated component, the anchoring steel bar 8 or the longitudinal beam in the beam. Tendon 7;

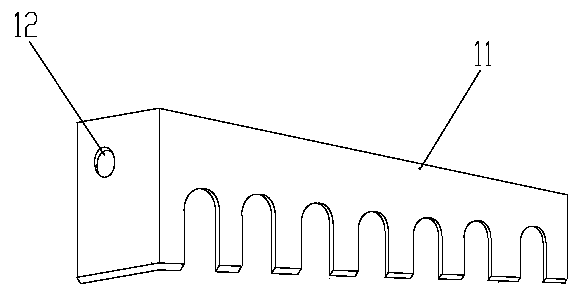

[0045] Before pouring the phosphorus and magnesium grouting material 3, a grouting sealing plate 11 is installed at the ...

Embodiment 2

[0051] A connection structure between prefabricated columns and beams based on phosphorus and magnesium materials. C-shaped steel clamping grooves 1 are respectively embedded in prefabricated columns 4 and prefabricated beams 5, and the openings of C-shaped steel clamping grooves 1 are arranged oppositely; The two ends of 2 are respectively clamped into the C-shaped steel slot 1 of the beam and column, and the phosphorus-magnesium grouting material 3 is poured into the gap between the C-shaped steel slot 1 and the connecting steel bar 2 with the anchor; A connecting structure obtained by installing stirrups 9 on the connecting steel bars 2 with anchor heads in room 1 and setting up the formwork, and pouring phosphorus magnesium fine stone concrete 10 at the joints.

Embodiment 3

[0053] A construction method for the connection structure of prefabricated columns and beams based on phosphorus and magnesium materials, comprising the following steps:

[0054] 1. Materials, components and equipment preparation

[0055] 1.1 According to the project design requirements and progress, make C-shaped steel slot 1, steel bar with anchor head 2, grouting sealing plate 11, stirrup 9 in the factory, make prefabricated columns 4, beams 5 and other components, and transport them to the project site ;

[0056] 1.2 According to the project design requirements and progress, transport the formwork, phosphorus magnesium grouting material 3, phosphorus magnesium fine stone concrete 10 mixed dry material, grouting and pouring equipment to the project site;

[0057] Wherein, the C-shaped steel slot 1 is made of steel material, such as figure 2 As shown, it is in the shape of a long strip with a C-shaped cross section. The back of the C-shaped steel slot 1 is welded with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com