Method for separating deposition film layer from accessory in vacuum coating cavity

A technology of vacuum coating and deposition film, applied in coating, gaseous chemical coating, metal material coating process, etc., can solve the problems of equipment operation failure and difficult to clean up the spray material thoroughly, so as to improve the yield and reduce labor. The trouble of cleaning, the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

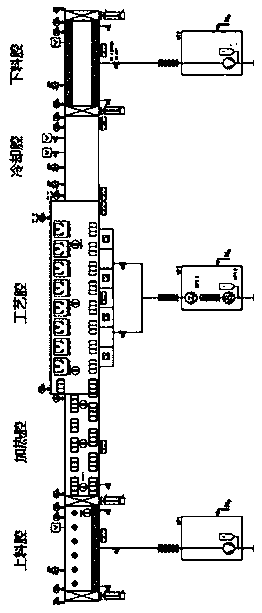

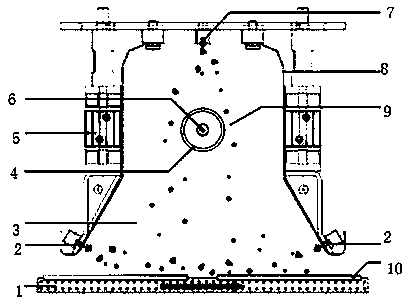

[0024] Example 1: see figure 1, a method for separating and depositing a film layer from accessories in a vacuum coating chamber. The method is as follows. In battery production, the plate PECVD coating is used as an example. The plate PECVD uses a vacuum coating principle. During the coating process, the silicon nitride deposition film left by the process will adhere to the surface of the cavity. Silicon nitride is an important structural ceramic material. It is a superhard substance that is inherently lubricious and wear-resistant, which makes it difficult to remove silicon nitride deposits during equipment maintenance. The silicon nitride deposition layer can be quickly and cleanly removed by using the technology of separating the deposited film layer from the fittings in the vacuum coating chamber. After raising the temperature of the chamber to 400°C-450°C, feed the liquid nitrogen coolant until the temperature drops to 50°C and then stop the feed. The cooling process i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com