Vapor-liquid separator

A vapor-liquid separator and liquid outlet technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high vapor resistance, low efficiency, incomplete separation of the separator, etc., and achieve high separation efficiency. , Easy installation and transportation, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

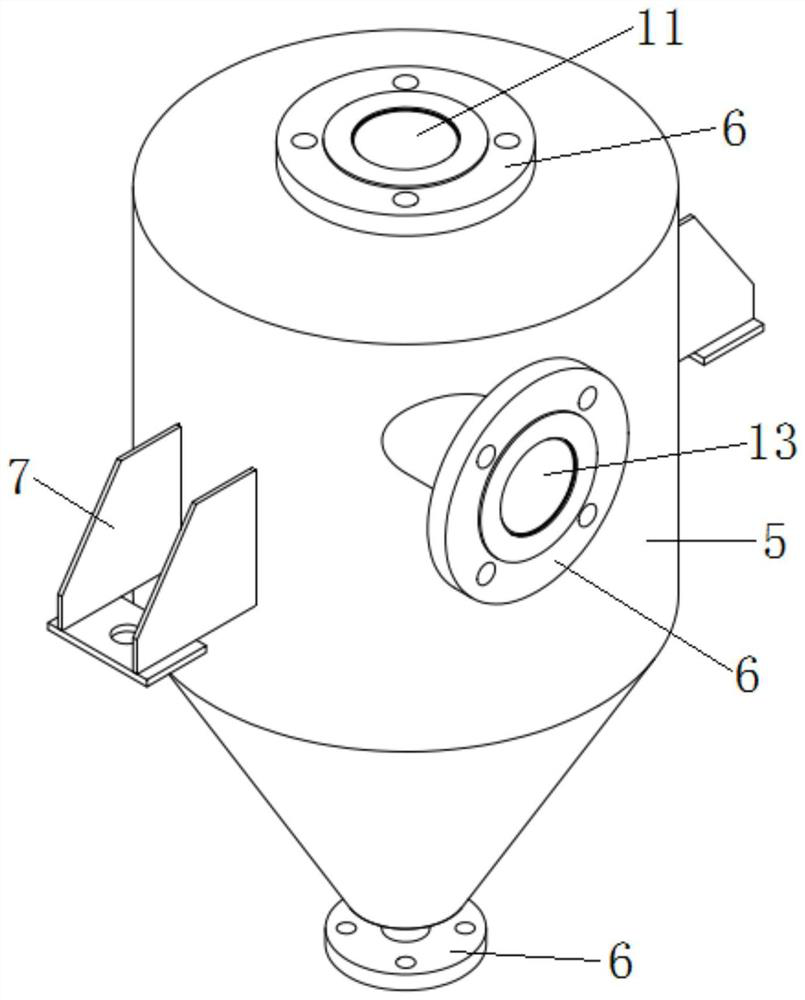

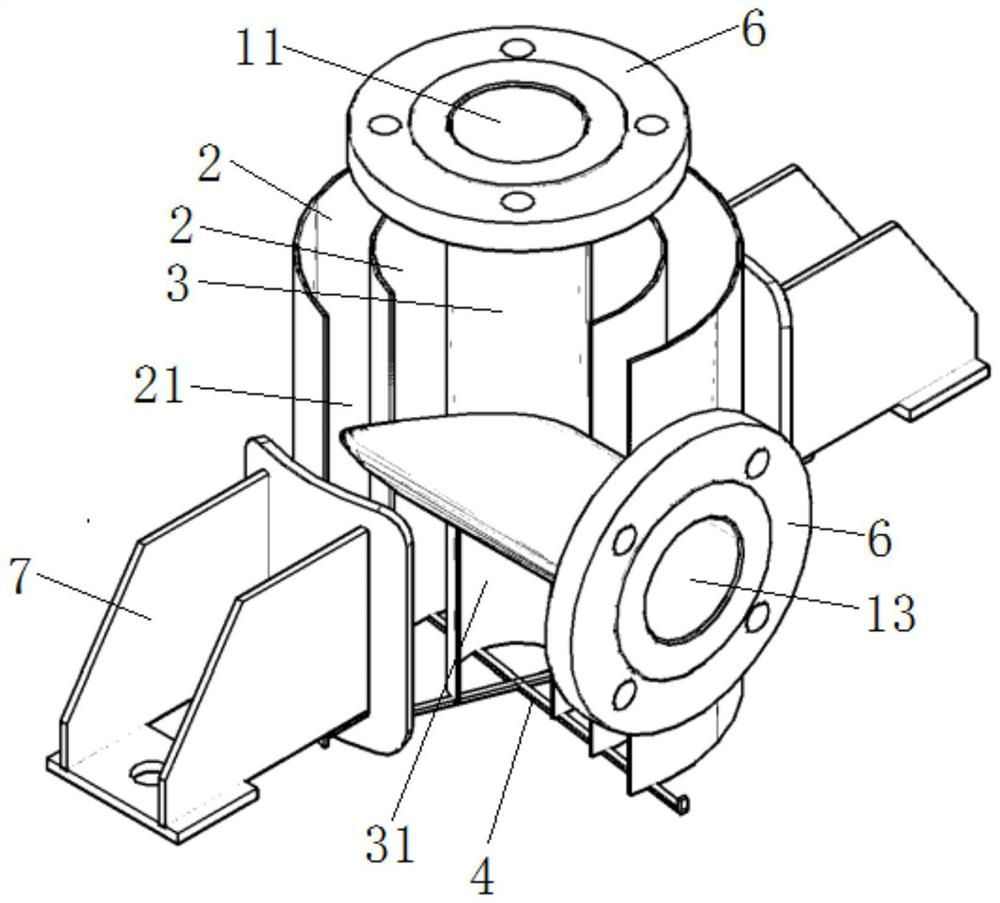

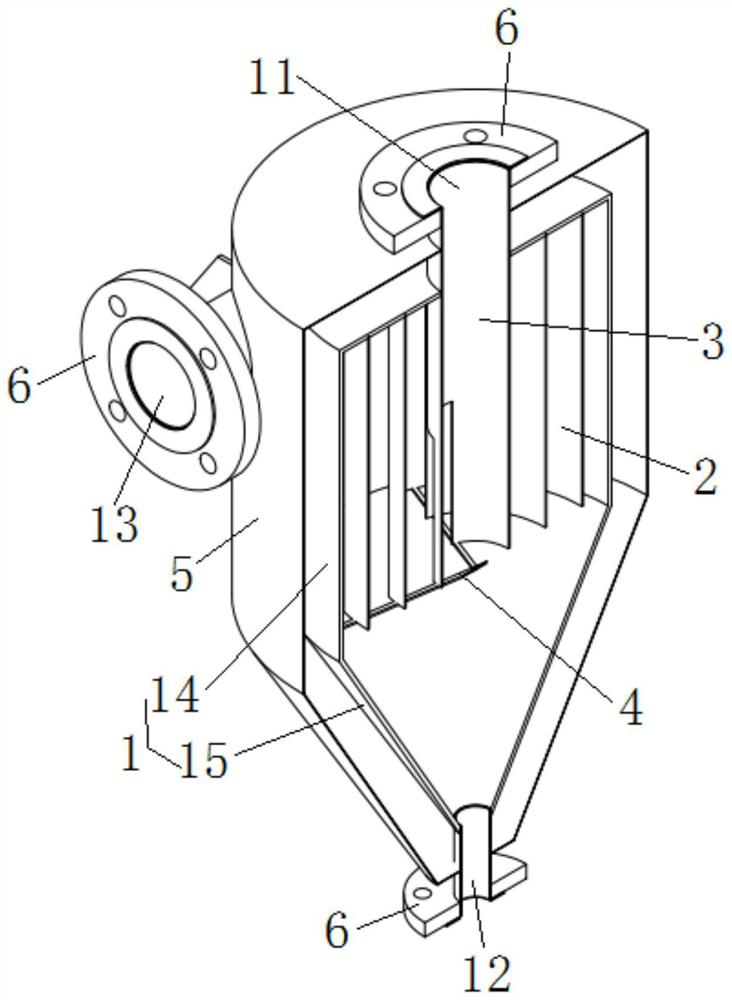

[0023] Such as Figure 1~3 As shown, a gas-liquid separator includes a cylinder body 1, a steam outlet 11 is arranged above the cylinder body 1, a liquid outlet 12 is arranged below the cylinder body 1, and the side of the cylinder body 1 There is a steam inlet 13 on the side, and a plurality of annular deflectors 2 are arranged inside the cylinder body 1, and the plurality of annular deflectors 2 are uniformly arranged in sequence from the inside to the outside, and the adjacent annular deflectors 2 to form an annular guide channel, the annular guide plate 2 is penetrated with a first opening 21 along its axial direction, the steam inlet 13 communicates with the annular guide channel through the first opening 21, and the inlet The steam port 13 is arranged along the tangential direction of the annular deflector 2, the steam inlet 13 is arranged opposite to the first opening 21, and the annular flow guide channel communicates with the liquid outlet 12; the cylinder body 1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com