Disposal process for fully standardized discharge of highly nondegradable organic wastewater

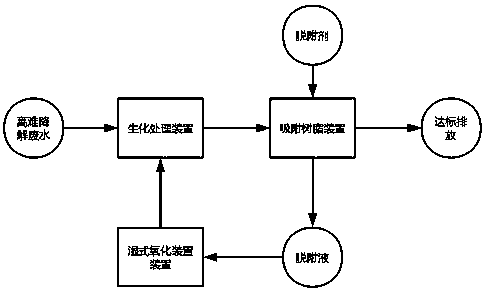

A treatment process and organic matter technology, which is applied in the field of high-refractory organic waste water to meet the discharge standards. It can solve the problems of low treatment load, environmental hazards, long treatment time, etc., and achieve high B/C ratio without secondary pollution. , to achieve the effect of fully meeting the emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

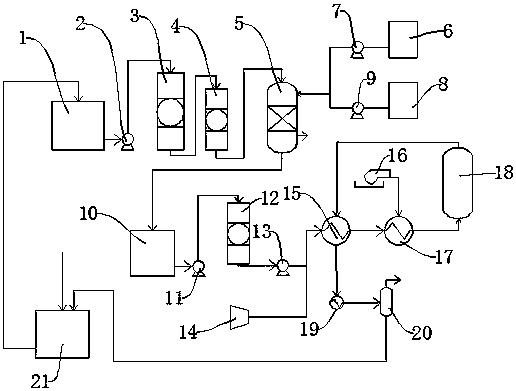

Embodiment 1

[0025] A treatment process for the high-refractory organic waste water to meet the standard discharge. The high-refractory organic waste water is first passed into the biochemical pool 21 for anaerobic treatment, and then flows to the raw water tank 1, driven by the booster pump 2, and then passes through the quartz sand filter 3 in turn. After being filtered by a precision filter 4 with a precision of 1 μm, it is passed into one of the adsorption tanks 5, and the adsorption tank 5 is filled with a macroporous adsorption resin. After the wastewater is absorbed by the macroporous adsorption resin, the waste water that meets the standard is discharged. The adsorption time is For 20 minutes, the adsorption temperature of the macroporous resin is 15°C, and the adsorption pressure is normal pressure. After a period of adsorption, there will be many adsorbates on the macroporous resin, which are basically refractory organic substances. At this time, the pipeline Switch to another ads...

Embodiment 2

[0027]A treatment process for the high-refractory organic waste water to meet the standard discharge. The high-refractory organic waste water is first passed into the biochemical pool 21 for anaerobic treatment, and then flows to the raw water tank 1, driven by the booster pump 2, and then passes through the quartz sand filter 3 in turn. After being filtered by a precision filter 4 with a precision of 5 μm, it is passed into one of the adsorption tanks 5. The adsorption tank 5 is filled with macroporous adsorption resin. After the waste water is adsorbed by the macroporous adsorption resin, the waste water that meets the standard is discharged. The adsorption time is 240min, the adsorption temperature of the macroporous resin is 50°C, and the adsorption pressure is normal pressure. After a period of adsorption, there will be many adsorbates on the macroporous resin, which are basically refractory organic substances. At this time, the pipeline Switch to another adsorption tank, ...

Embodiment 3

[0029] A treatment process for the high-refractory organic waste water to meet the standard discharge. The high-refractory organic waste water is first passed into the biochemical pool 21 for anaerobic treatment, and then flows to the raw water tank 1, driven by the booster pump 2, and then passes through the quartz sand filter 3 in turn. After being filtered by a precision filter 4 with a precision of 3 μm, it is passed into one of the adsorption tanks 5, and the adsorption tank 5 is filled with a macroporous adsorption resin. After the waste water is adsorbed by the macroporous adsorption resin, the waste water that meets the standard is discharged. The adsorption time is 150min, the adsorption temperature of the macroporous resin is 35°C, and the adsorption pressure is normal pressure. After a period of adsorption, there will be many adsorbates on the macroporous resin, which are basically refractory organic substances. At this time, the pipeline Switch to another adsorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com