Manufacturing method of digitalized implanting guide adhesive guide plate and guide adhesive guide plate

A production method and guide plate technology, applied in the medical field, can solve problems such as frequent visits to the doctor, deviation of the position of the restoration, and long clinical operation time, and achieve the effects of reducing the number of visits to the doctor, reducing the time for restoration, and streamlining the design process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

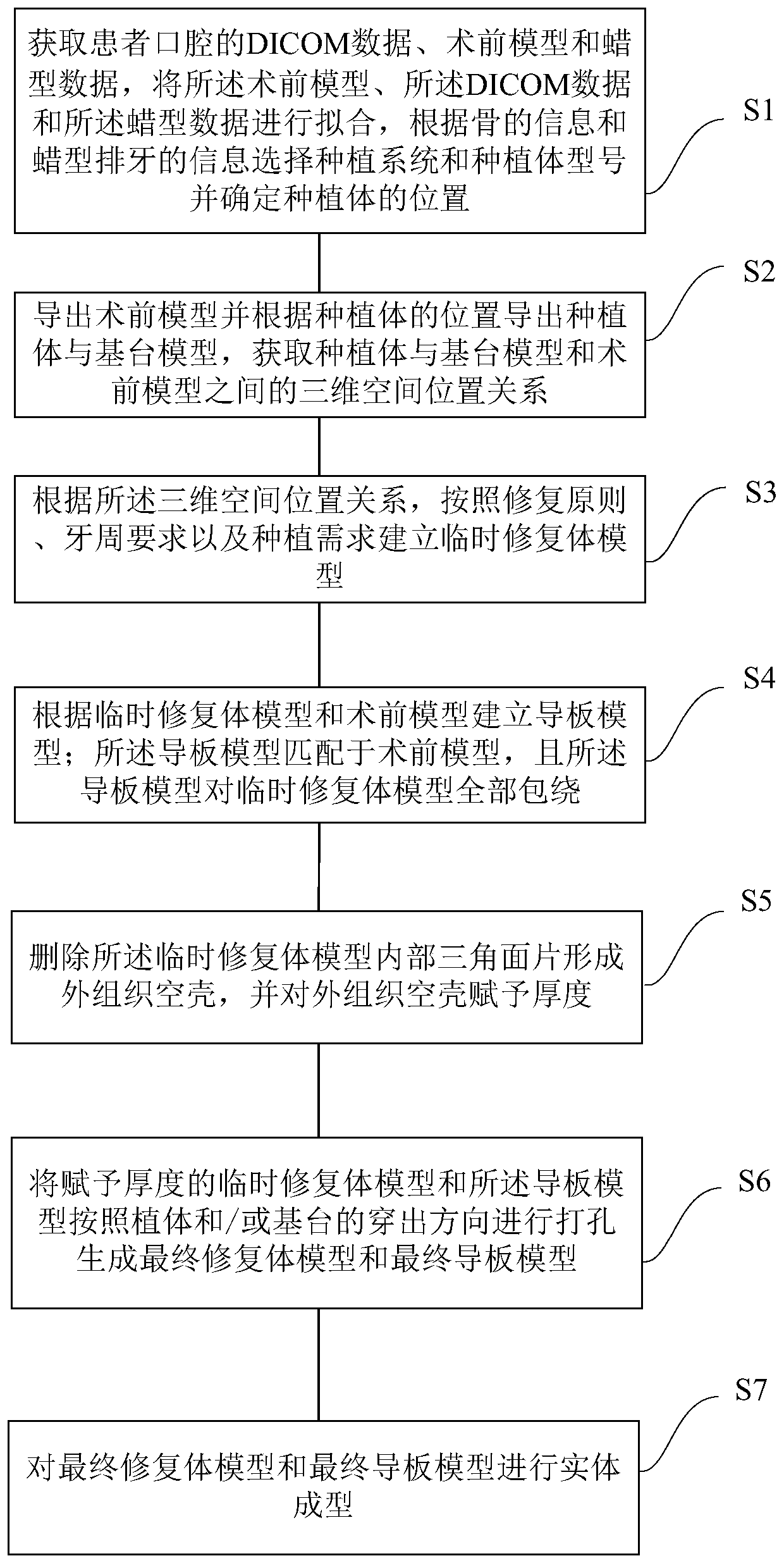

[0035] Such as figure 1As shown, the manufacturing method of the digital implant guide bonding guide plate of the present invention includes the following steps: S1: Acquire the DICOM data, preoperative model and wax-up data of the patient's oral cavity, and combine the preoperative model, the DICOM data and the Fit the wax-up data, select the implant system and implant model according to the bone information and the wax-up teeth information, and determine the position of the implant; S2: Export the preoperative model and export the implant and abutment according to the position of the implant Model, to obtain the three-dimensional spatial positional relationship between the implant and the abutment model and the preoperative model; S3: According to the three-dimensional spatial positional relationship, establish a temporary restoration model according to the restoration principle, periodontal requirements, and implant requirements; S4: According to The temporary restoration m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com