Mechanism for automatically baking sweet potatoes and temperature control system

A temperature control system and temperature control technology, applied in baking, food ovens, food science, etc., can solve the problems of poor sweet potato finished products, poor finished products, and ineffective and accurate temperature, so as to ensure the effect of temperature control and temperature data. Accurate and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

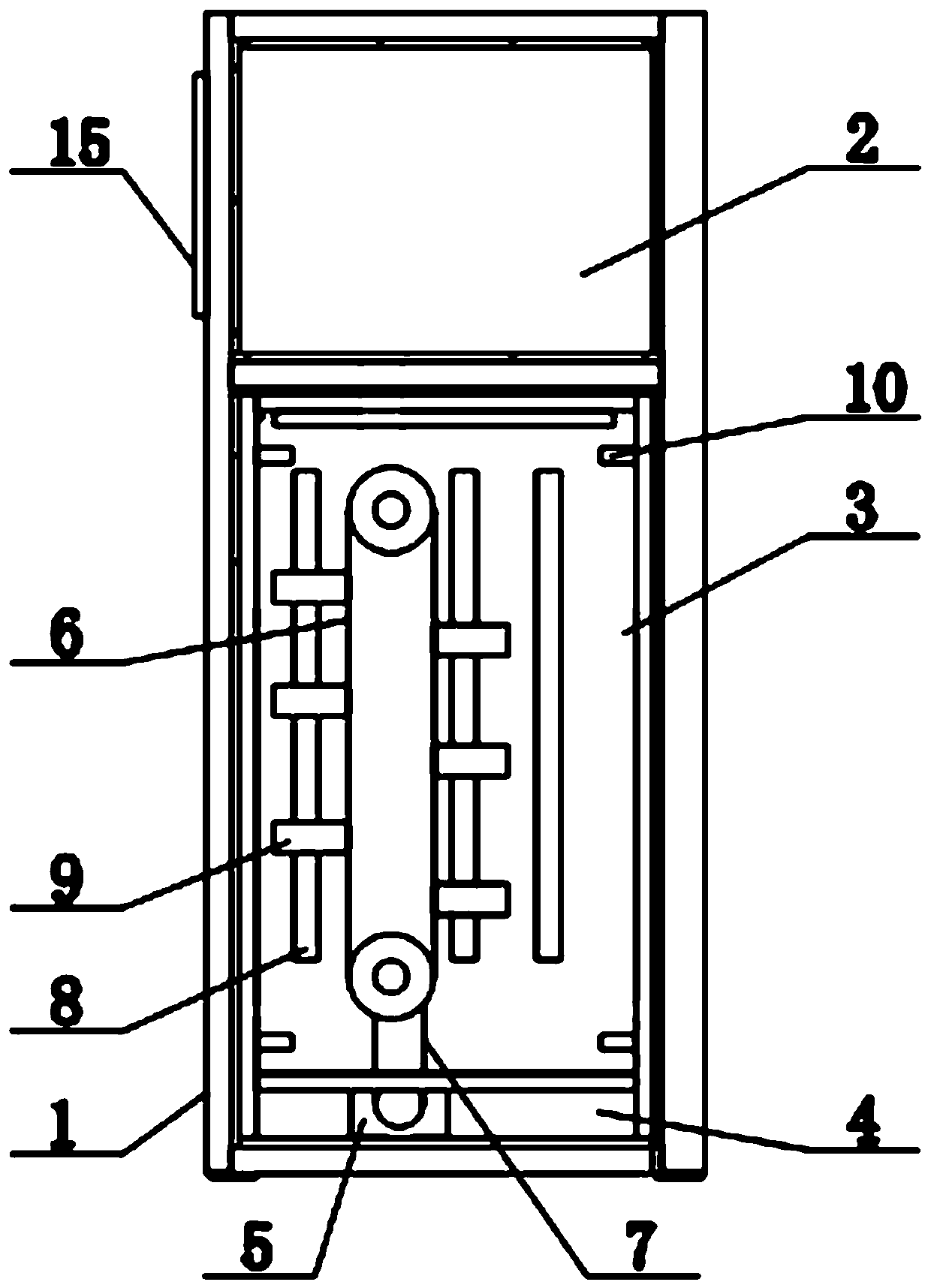

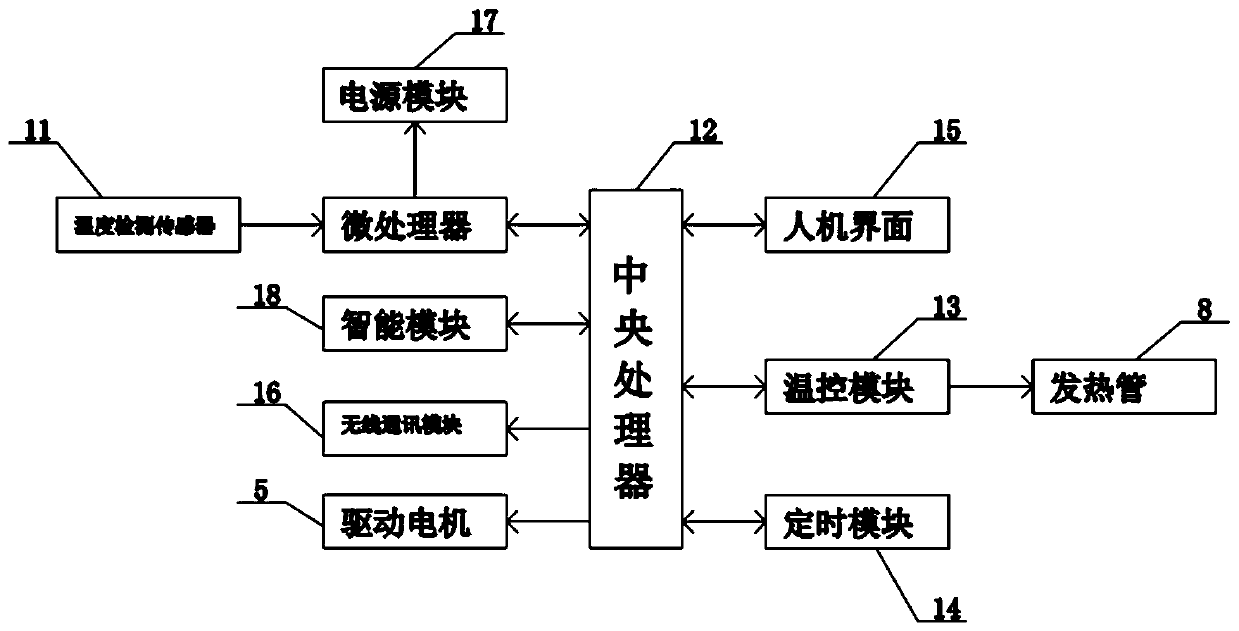

[0031] see figure 1 , figure 2 , a mechanism for automatically roasting sweet potatoes and a temperature control system, including a sweet potato grilling mechanism and a temperature control mechanism, the sweet potato grilling mechanism includes a cabinet body 1, a driving mechanism and a baking mechanism, and the cabinet body 1 includes an upper layer 2, a middle layer 3, and a lower layer 4 , the driving mechanism includes a driving motor 5 and an operating chain 6, and the driving motor 5 is installed on the lower layer 4 of the cabinet 1, and the operating chain 6 is installed on the middle layer 3 of the cabinet 1, while the operating chain 6 adopts two groups in the middle of the cabinet 1 The corresponding rotation of the rotating shaft is connected to the upper and lower sides of the middle layer 3 of the cabinet body 1. The operating chain 6 is arranged between the two groups of rotating shafts. The connecting chain 7 connects the driving motor 5 and the rotating sh...

Embodiment 2

[0041] see figure 1 , figure 2 , a mechanism and temperature control system for automatically roasting sweet potatoes, which are basically the same as in Embodiment 1. Furthermore, the middle layer 3 of the cabinet 1 is provided with a sales port corresponding to the sweet potato placement hanging basket 9, and the sales port is mainly used for selling sweet potatoes. , and an automatic vending system is provided, and the vending port can also be used by the staff to place raw sweet potatoes in the sweet potato hanging basket 9 inside;

[0042] There is a smoke exhaust pipe on one side of the upper layer 2 of the cabinet body 1. One end of the smoke exhaust pipe is connected to the middle layer 3 of the cabinet body 1, and the other end is connected to the outside world. An exhaust fan is arranged on the smoke exhaust pipe to discharge the internal smoke exhaust, and the exhaust fan is electrically connected to the temperature control module 13, and when the temperature cont...

Embodiment 3

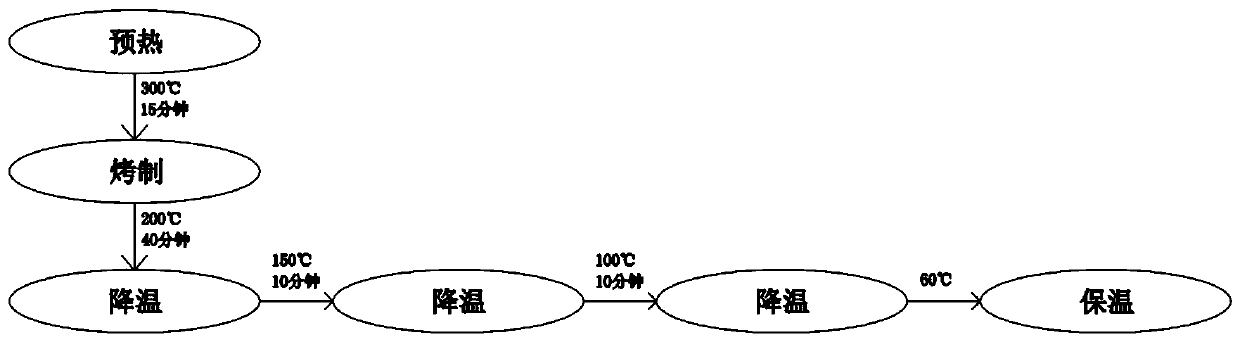

[0049] see figure 1 , figure 2 , a mechanism for automatically roasting sweet potatoes and a temperature control system, the temperature control process of which is: the preheating operation and the setting of the preheating time are issued through the man-machine interface 15, the operation signal will be sent to the central processing unit 12, and the central processing unit 12 Control the heating pipe 8 to generate heat, the heating pipe 8 will heat the middle layer 3 of the cabinet 1, and the four groups of temperature detection sensors 10 will detect and collect the heating temperature, and transmit the collected temperature to the microprocessor 11, which is controlled by the microprocessor 11. Processor 11 calculates, obtains the average value, and transmits the average temperature to the central processing unit 12. When the temperature calculated by the microprocessor 11 reaches the preheating temperature, the central processing unit 12 transmits a signal to the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com