High-altitude installation operation efficiency visual management system

A management system and high-altitude operation technology, applied in closed-circuit television systems, location-based services, etc., can solve the problems of lack of real-time monitoring and display tracking and early warning mode, high degree of visualization and accuracy, and material cost, saving manpower As well as the cost of time, the effect of improving accuracy and reliability, and improving the efficiency of aerial work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] Such as Figure 1-2 As shown, a high-altitude installation operation efficiency visualization management system, such as figure 1 As shown, including positioning system, electronic fence, signal base station and electronic chip equipment, electronic chip equipment includes safety boots and bracelets;

[0028]The electronic chip equipment and the positioning system are interactively connected through the signal base station, and the electronic fence is set at the periphery of the high-altitude installation operation. The positioning of electronic chip equipment is realized through the positioning system, and the positioning position is compared with the area of the electronic fence to realize the visual monitoring and early warning of the efficiency of high-altitude installation operations.

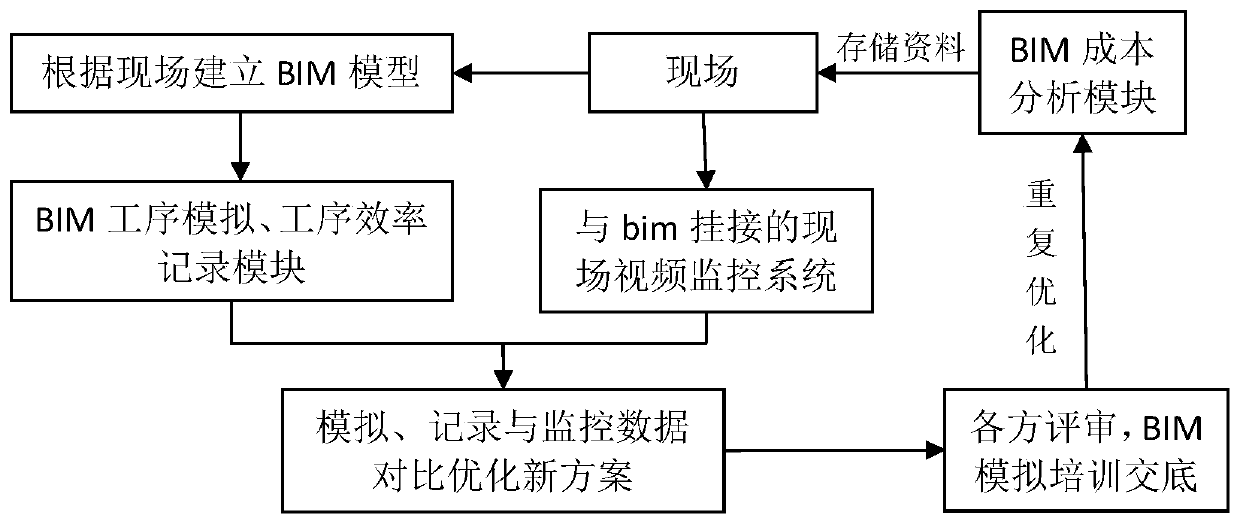

[0029] Build a BIM model on the BIM platform on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com