Process for preventing lithium ion battery pole piece from powder shedding during processing

A lithium-ion battery and processing technology, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve problems such as increased power consumption, powder removal, and increased production costs, to improve wetting effect, enhance liquid absorption capacity, increase The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

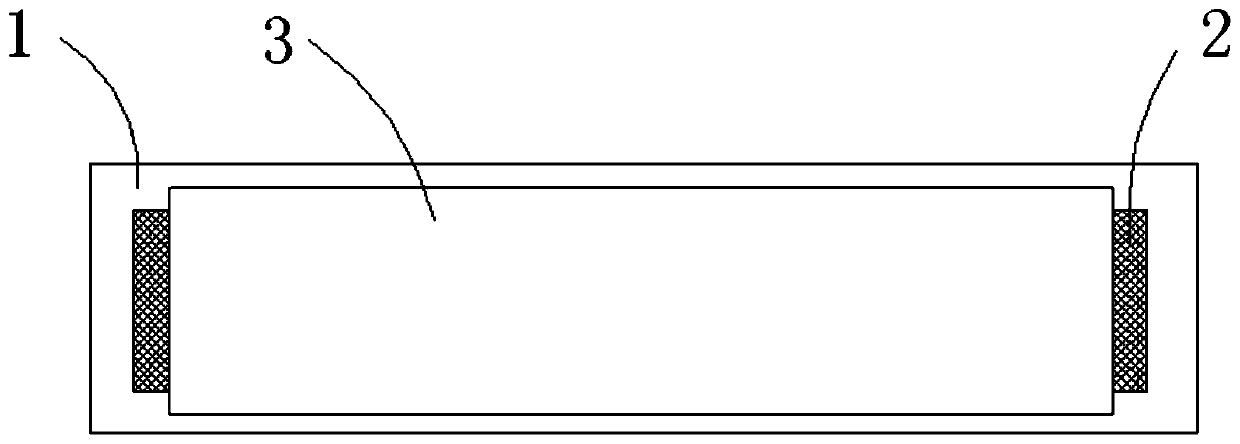

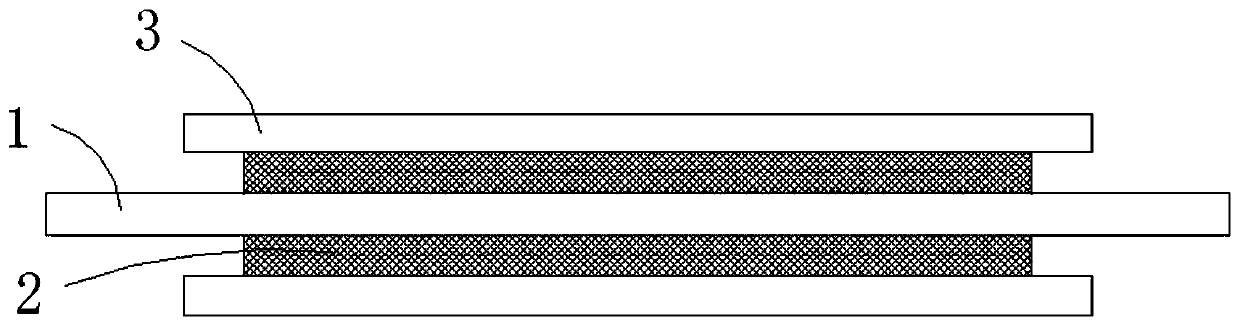

[0033] Dissolve PVDF in NMP to make PVDF glue with a solid content of 6.0%, and coat it on the unrolled graphite negative electrode sheet. The thickness of the PVDF glue layer is 1-3 μm. The coating method is as follows: figure 1 , figure 2 , Both sides of the current collector 1 are the pole piece coating 2, and the outer surface of the pole piece coating 2 is coated with a protective layer 3, and the protective layer 3 is an adhesive layer or a ceramic coating.

Embodiment 2

[0035] Dissolve PVDF in NMP to make PVDF glue, then add ceramic powder to make ceramic slurry, wherein the mass ratio of PVDF to ceramic is 3:1, and the solid content of the slurry is 20%. On the roll-pressed positive electrode sheet, the thickness of the PVDF+ceramic coating is 5-8 μm, and the coating method is as follows: figure 1 , figure 2 .

Embodiment 3

[0037] Dissolve CMC in deionized water to make CMC glue with a solid content of 1.5%, and coat it on the non-rolled silicon carbon negative electrode sheet. The thickness of the CMC glue layer is 10-12 μm. The coating method is as follows: figure 1 , figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com