A kind of anti-corrosion NdFeB magnet and preparation method thereof

A neodymium-iron-boron and magnet technology is applied in the field of anti-corrosion neodymium-iron-boron magnets and their preparation, which can solve the problems of high requirements for coating integrity, high rejection rate, and easy peeling of coatings, so as to improve product acceptance and have little impact on magnetic properties. , reduce the effect of formula adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

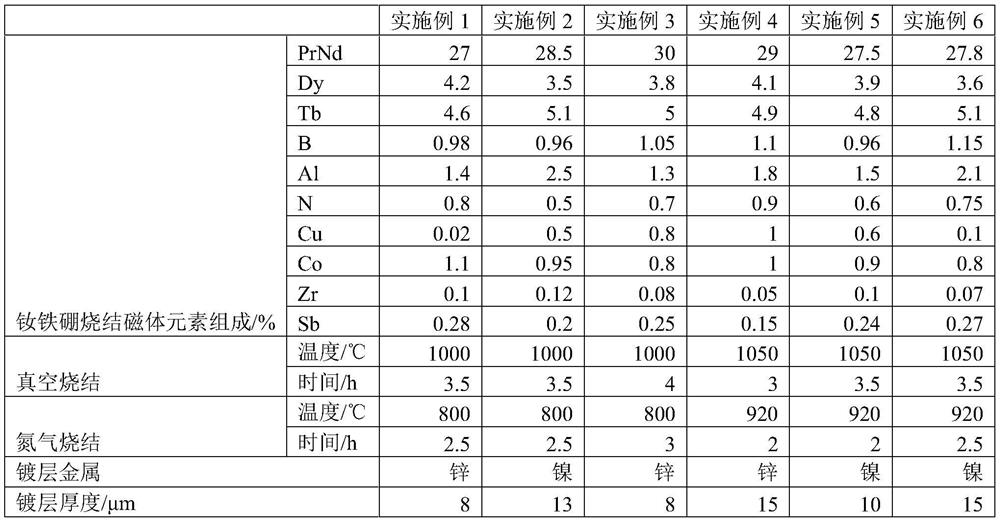

Embodiment 1~6

[0050] as attached figure 1 As shown, a kind of anti-corrosion NdFeB magnet, comprises NdFeB sintered magnet 1 and the anti-corrosion coating 2 on the outside of Nd-Fe-B sintered magnet 1 (in the accompanying drawing, for reflecting the existence of anti-corrosion coating 2, the thickness of anti-corrosion coating 2 in the accompanying drawing Far greater than the actual thickness of the anti-corrosion coating 2, the anti-corrosion coating 2 in the drawings is only for illustration, the actual thickness of the sintered NdFeB magnet 1 and the anti-corrosion coating 2 depends on the actual design and production).

[0051] NdFeB sintered magnet 1 is sintered NdFeB magnet, and its shape can be determined according to actual product requirements. The specifications of the anti-corrosion NdFeB magnet and NdFeB sintered magnet 1 that appear below in this application are determined by referring to the sample requirements during the test , which is a test sample product, not the limite...

Embodiment 7

[0099] An anti-corrosion NdFeB magnet, based on the basis of Example 4, the difference is that the NdFeB formula is adjusted without adding Dy, Tb, Sb element materials, and the obtained NdFeB sintered magnet internal element detection results Nd: 30wt%; B: 1.05wt%; Al: 1.3wt%; N: 0.7wt%; Cu: 0.8wt%; Co: 0.8wt%;

Embodiment 8

[0120] An anti-corrosion NdFeB magnet, on the basis of Example 4, change the time of its electroplating coating to obtain Examples 8A-8D with different thicknesses of the anti-corrosion coating 1, and the thickness of the anti-corrosion coating in Examples 8A-8D is shown in Table 5 .

[0121] Table five. The thickness parameter table of embodiment 8 anticorrosion coating

[0122] Example 8A Example 8B Example 8C Example 8D Anti-corrosion coating thickness / μm 5 8 17 20

[0123] The anticorrosion performance test of the complete coating in the anticorrosion performance test was carried out on the NdFeB magnet prepared in Example 8, and the test results are shown in Table 6.

[0124] Table six. Embodiment 8 complete coating anticorrosion performance test result table

[0125] test Test parameters Example 8A Example 8B Example 8C Example 8D Anti-corrosion performance testing NdFeB magnet rust time A / h 73 88 130 140 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com