A rebound rebound instrument for engineering supervision

A rebound tester and supervision technology, applied in instruments, scientific instruments, testing material hardness, etc., can solve the problems of reduced precision and inconvenient operation, and achieve the effect of reducing resistance, improving service life, and reducing the number of maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

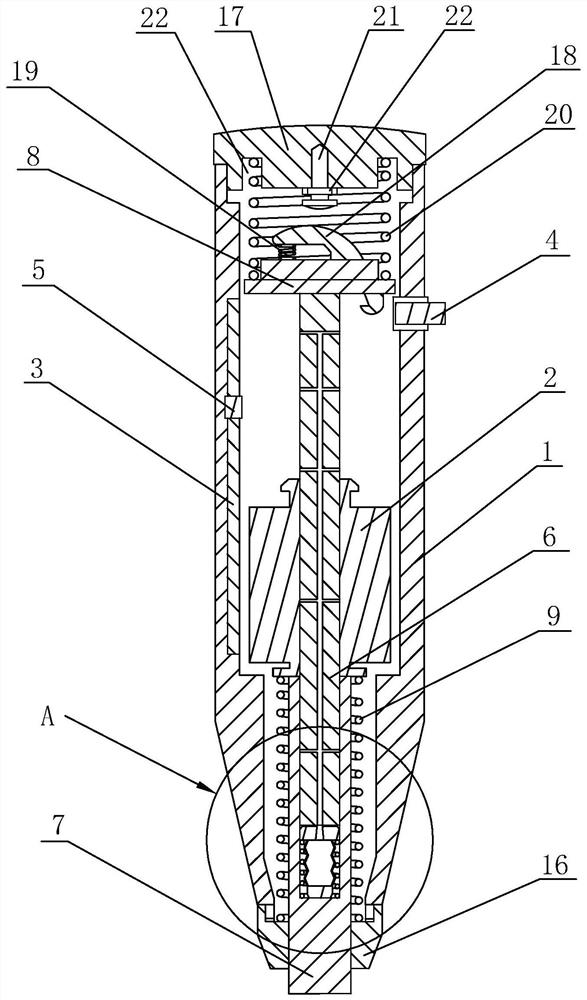

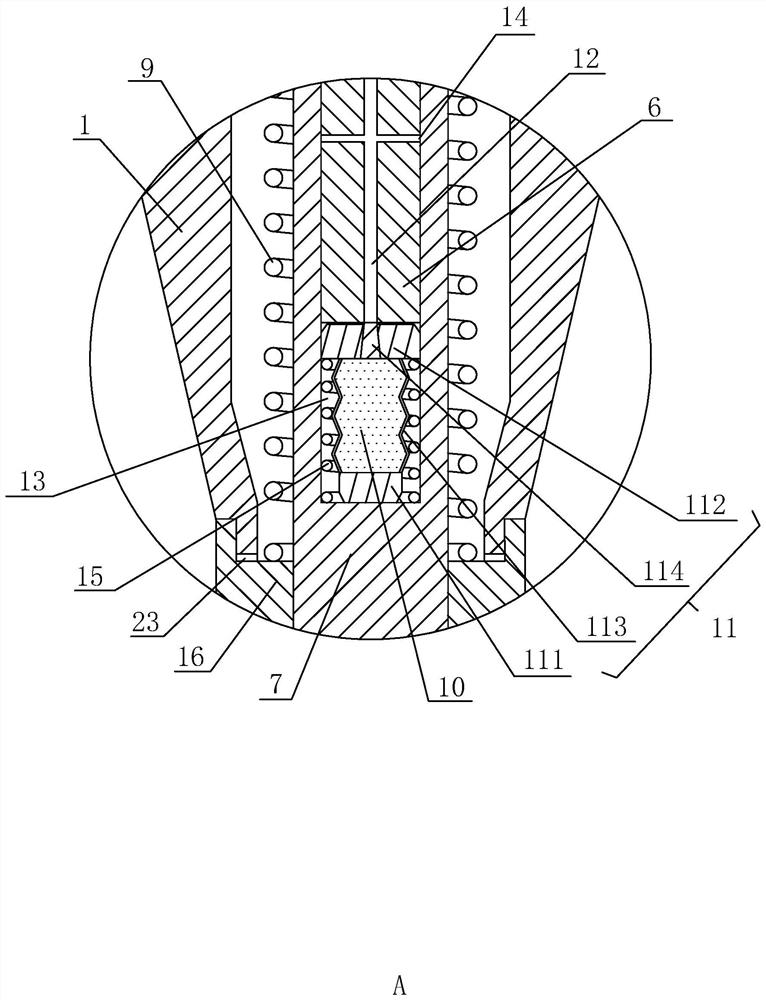

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] refer to figure 1 , is a rebound hammer for engineering supervision disclosed by the present invention, comprising a cylinder body 1, the head and tail ends of the cylinder body 1 are open structures and are respectively threaded with a head cover 16 and a tail cover 17, and the head cover 16 faces the cylinder body 1 A sealing ring 24 is embedded on one side. The sealability of the joint between the head cover 16 and the cylinder body 1 is improved by the sealing ring 24 . The inner wall of the barrel 1 is embedded with a scale 3 along its axial direction. The scale 3 is made of transparent material and marked with scales. A pointer slider 5 is provided on the scale 3 to slide along its length direction.

[0033] A guide flange 8 is slid inside the barrel 1 along its axis. The guide flange 8 is located at one end of the barrel 1 close to the end cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com