Pipeline based on electrical control for water cooling device

A water-cooling device and electrical control technology, which is applied to tubular components, lighting and heating equipment, heat exchange equipment, etc., can solve the problems of inability to meet cooling requirements, uneven cooling surface heat dissipation density, inconsistent heat dissipation requirements, etc., to improve heat conduction Effect, improvement of cooling efficiency and cooling quality, effect of multi-heat exchange cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

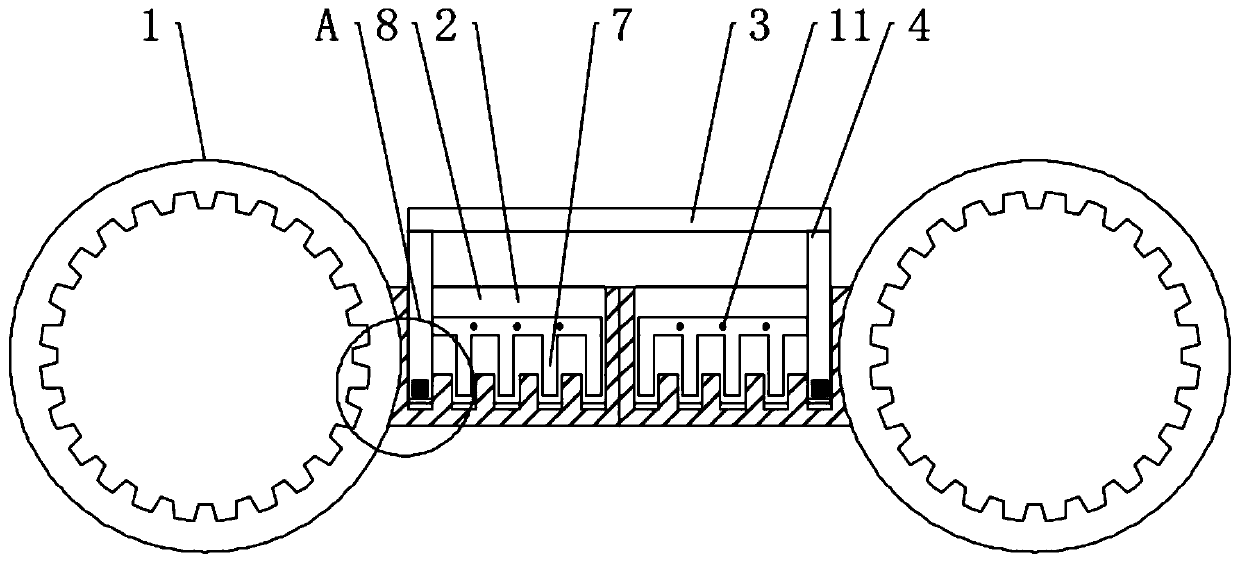

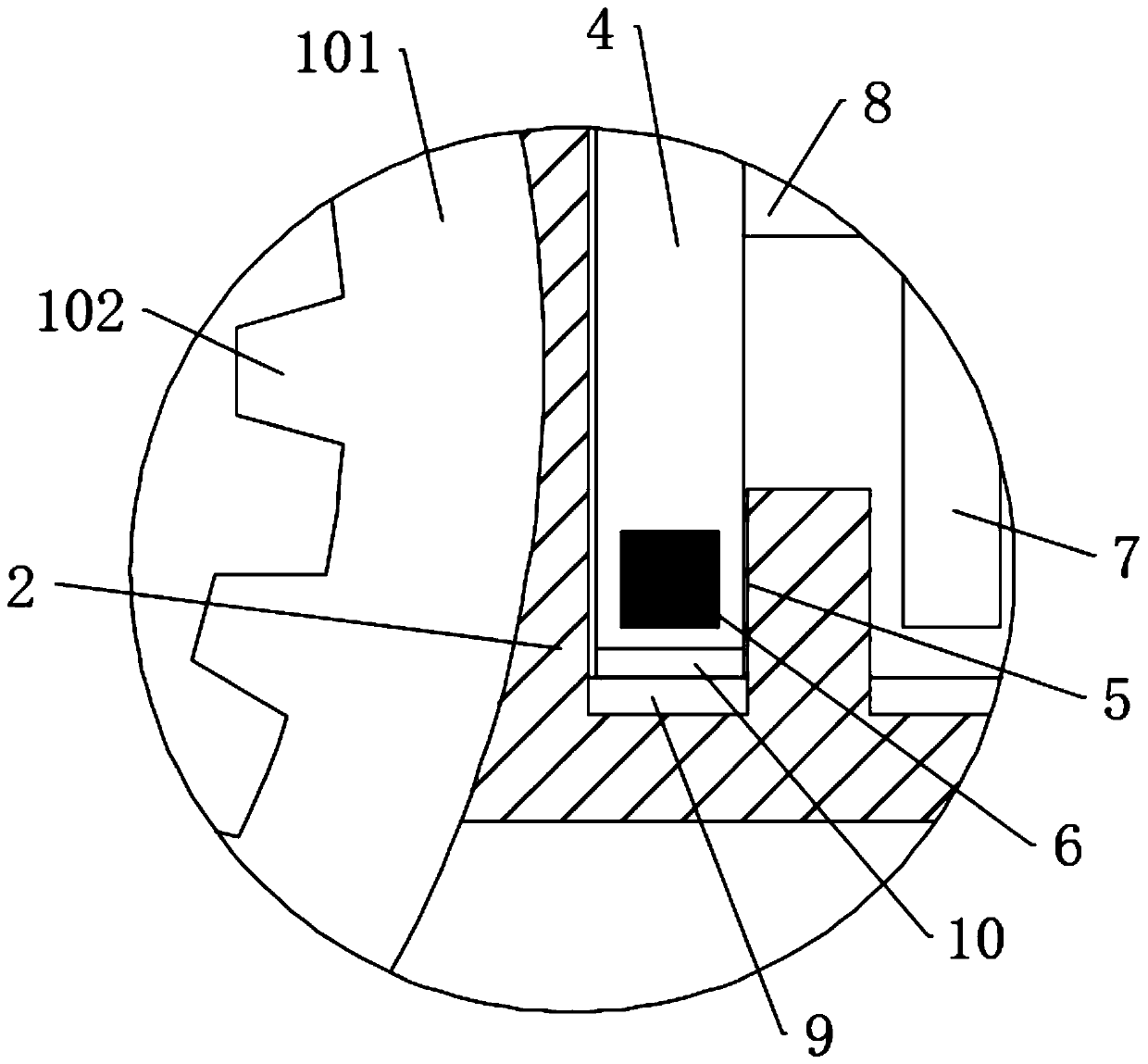

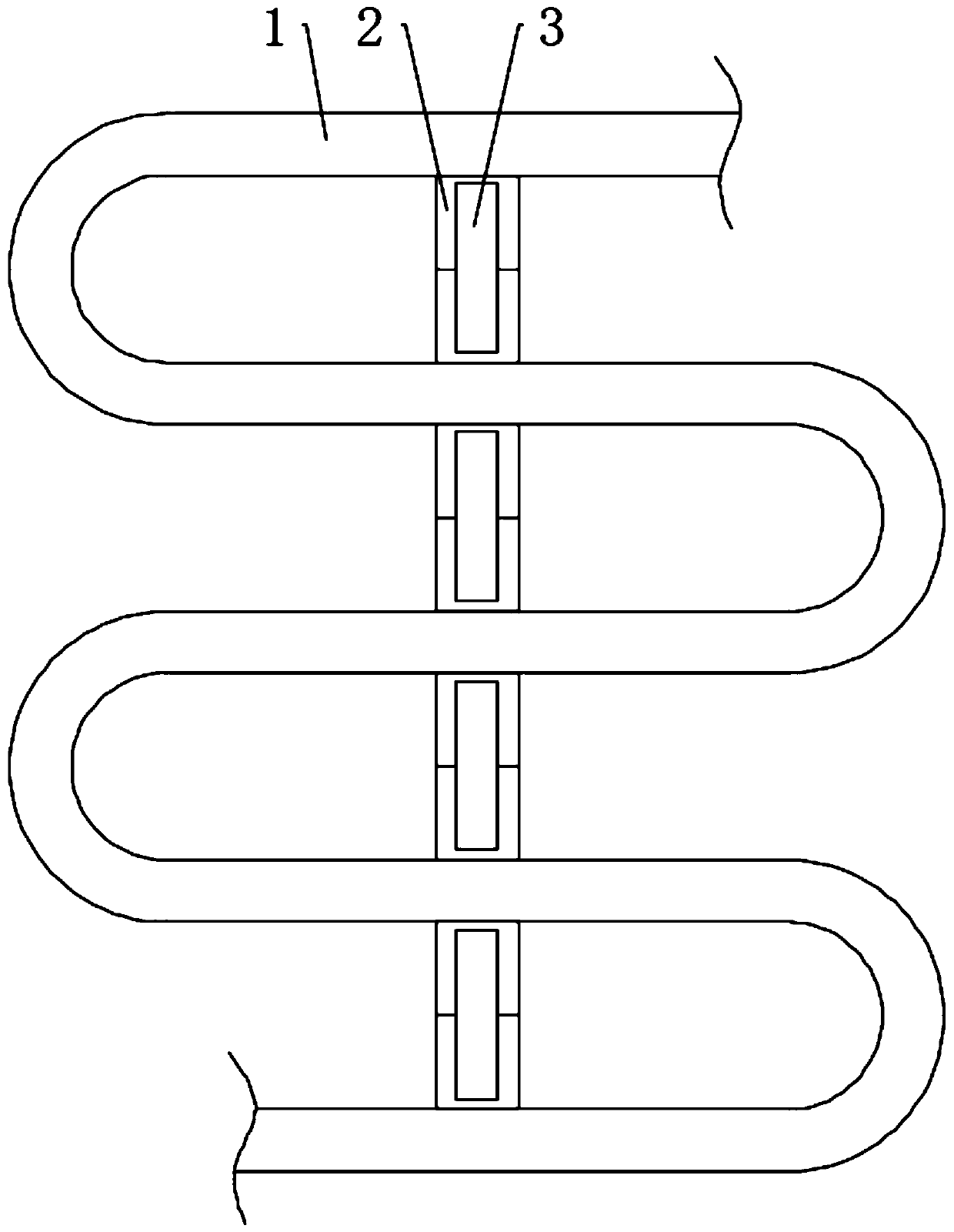

[0036] see Figure 1-3, a pipe for a water-cooling device based on electrical control, comprising a detour pipe 1, the detour pipe 1 is a plastic elastic hose, the inner end of the detour pipe 1 is fixedly connected with a heat conduction net, the heat conduction net is coated with a corrosion-resistant layer, and the heat conduction net is made of metal It is made of copper, and it is closely fitted around the inner end of the circuitous pipeline 1 at the same time, which further improves the heat conduction effect, and then improves the cooling effect of the circuitous pipeline 1. The circuitous pipeline 1 includes a pipeline body 101, and the inner end of the pipeline body 101 is fixedly connected with a number of evenly distributed inner tubes. The protrusion 102 is integrally formed between the pipe body 101 and the inner protrusion 102. Through the setting of the inner protrusion 102, the contact area between the detour pipe 1 and the cooling medium can be increased, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com