DPF active regenerative intake control system and method using scr gas-assisted structure

A technology of active regeneration and control system, which is applied in the direction of electronic control of exhaust gas treatment device, diagnosis device of exhaust gas treatment device, exhaust device, etc. problems, to achieve the effect of reducing use, reducing HC slip, and promoting oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

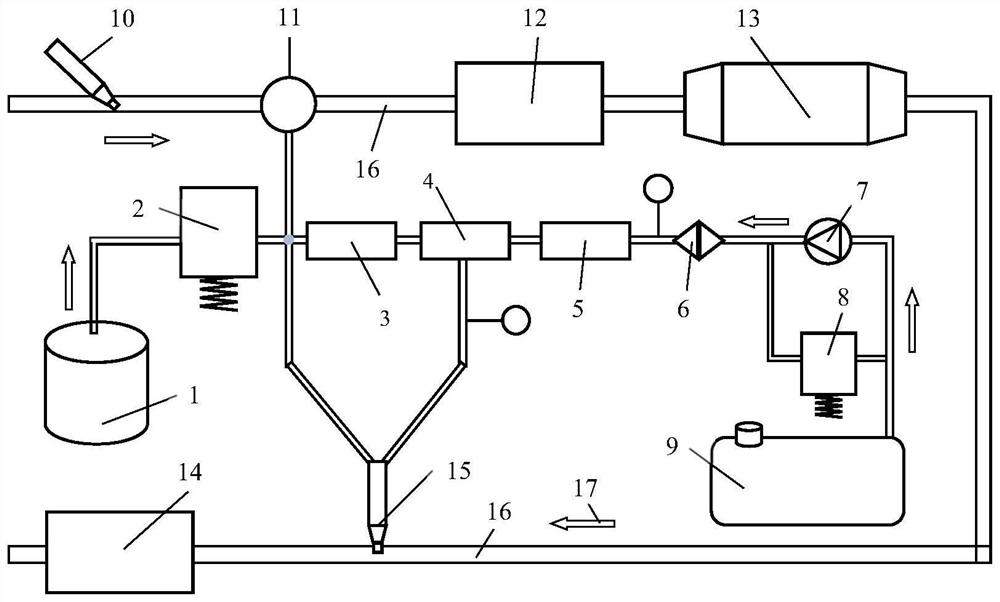

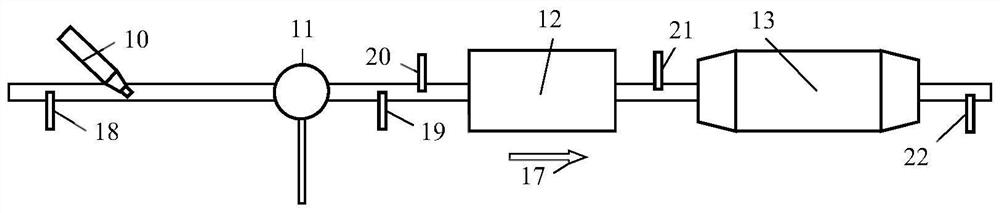

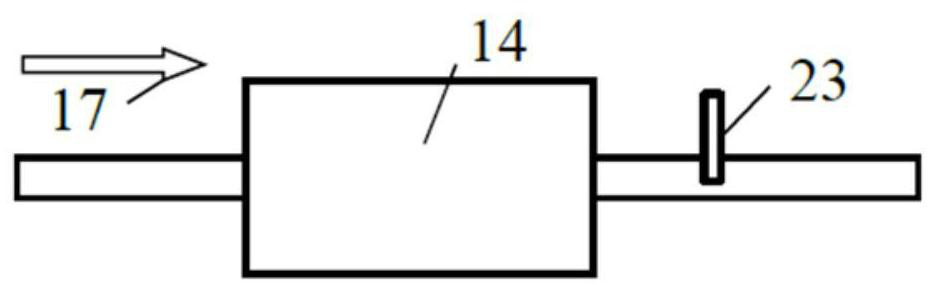

[0033] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

[0034] A DPF active regeneration air intake control system and method using a diesel engine SCR (Selective Catalytic Reduction) gas-assisted structure proposed by the present invention can promote the full oxidation of hydrocarbons (HC) in the DOC and reduce HC slippage. It can effectively control the internal temperature peak of the DPF during active regeneration, and reduce the occurrence of DPF failure; it can increase the evaporation and atomization uniformity of injected fuel before DOC, reduce additional devices, and effectively reduce the cost of diesel engine exhaust af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com