Active fermentation object and preparation method and application thereof

A fermented product and active technology, applied in the field of active fermented product and its preparation, can solve problems such as the decrease of β-glucan content, achieve the effects of increased yield and purity, low production cost, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

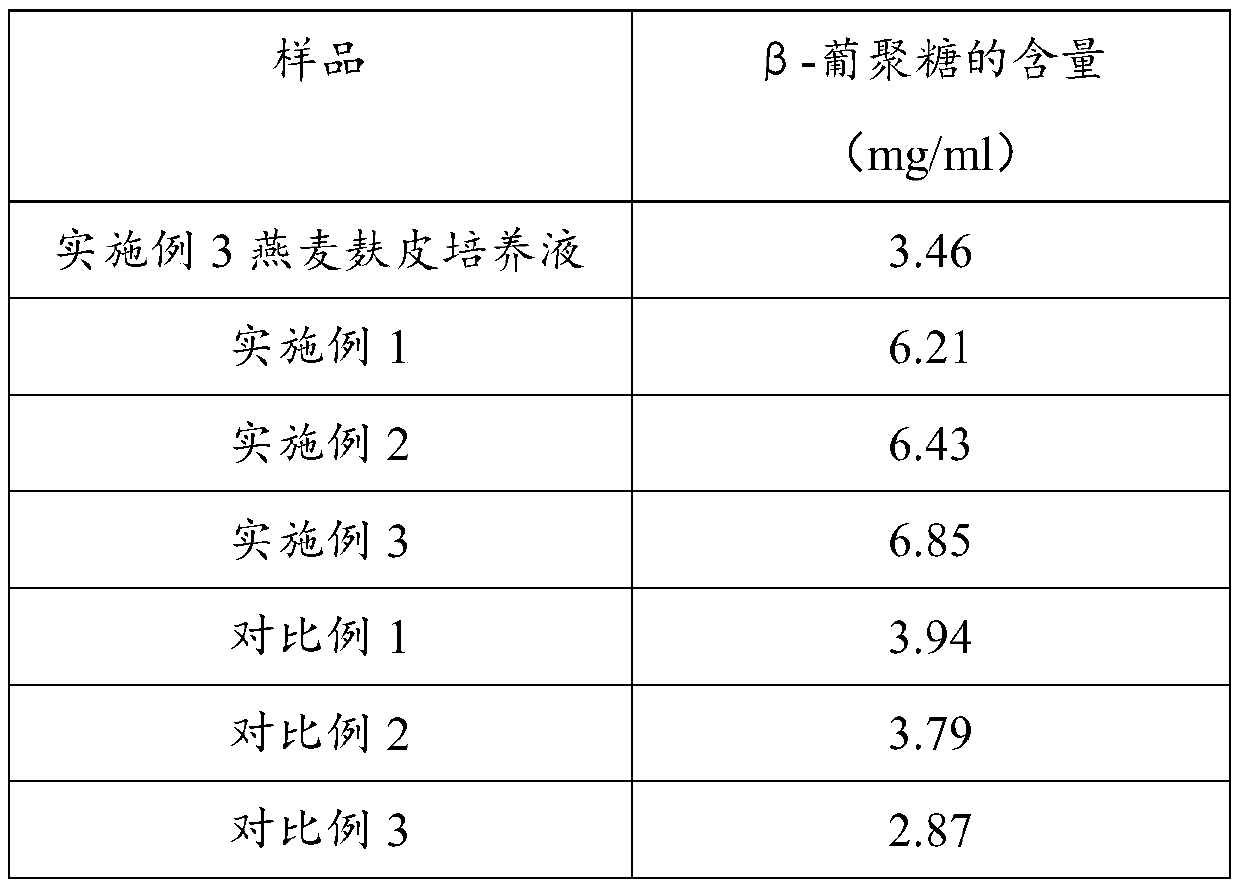

Examples

Embodiment 1

[0034] Embodiment 1, active fermented product of the present invention and preparation method thereof

[0035] S1. Mix oat bran and water according to the material-to-liquid ratio of 1:10 (W / V, g / mL), then use protease, glucoamylase and amylase to carry out enzyme treatment in turn, and then sterilize after the enzyme treatment to obtain oat Bran culture fluid;

[0036] The steps of the enzyme treatment are as follows:

[0037] a1, protease treatment: adjust the pH value to 6-7, then add papain with 1% weight of oat bran culture solution, and bathe in 60°C water bath for 120min;

[0038] a2, glucoamylase treatment: adjust the pH value to 4.0-4.5, add 1% glucoamylase by weight of the oat bran culture solution, and bathe in 55°C water for 3 hours;

[0039] a3. Amylase treatment: add 1% α-amylase by weight of oat bran culture solution (the α-amylase is freeze-dried powder, its weight percentage is 10%), and bathe in 70° C. water for 40 minutes.

[0040] S2. Get the oat bran cu...

Embodiment 2

[0046] Embodiment 2, active fermented product of the present invention and preparation method thereof

[0047] S1, take oat bran and water and mix according to the ratio of material to liquid 1:25 (W / V, g / mL), then use protease, glucoamylase and amylase to carry out enzymatic treatment successively, carry out sterilization after enzymatic treatment, make oat Bran culture fluid;

[0048] The steps of the enzyme treatment are as follows:

[0049] a1, protease treatment: adjust the pH value to 6-7, then add ficin with 5% weight of oat bran culture solution, and bathe in water at 65°C for 90 minutes;

[0050] a2, glucoamylase treatment: adjust the pH value to 4.0-4.5, add 3% glucoamylase by weight of oat bran culture solution, and bathe in water at 60°C for 2 hours;

[0051] a3. Amylase treatment: add 5% α-amylase by weight of oat bran culture solution (the α-amylase is freeze-dried powder, its weight percentage is 10%), and bathe in 75° C. water for 30 minutes.

[0052] S2. Ge...

Embodiment 3

[0058] Embodiment 3, active fermented product of the present invention and preparation method thereof

[0059] S1. Mix oat bran and water according to the ratio of material to liquid 1:15 (W / V, g / mL), then use protease, glucoamylase and amylase to carry out enzyme treatment in turn, and then sterilize after the enzyme treatment to obtain oat Bran culture fluid;

[0060] The steps of the enzyme treatment are as follows:

[0061] a1, protease treatment: adjust the pH value to 6-7, then add papain with 3% weight of oat bran culture solution, and bathe in 60°C water bath for 100min;

[0062] a2. Glucoamylase treatment: adjust the pH value to 4.0-4.5, add 2% glucoamylase by weight of the oat bran culture solution, and bathe in water at 60°C for 2.5 hours;

[0063] a3. Amylase treatment: add 3% α-amylase by weight of oat bran culture solution (the α-amylase is freeze-dried powder, its weight percentage is 10%), and bathe in 75° C. water for 30 minutes.

[0064] S2. Get the oat br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com