A kind of magnetic phase change microcapsule and preparation method thereof

A phase change microcapsule, magnetic phase change technology, applied in the field of light industry technology and functional materials, can solve the problems of thermal conductivity and other issues, and achieve the effect of increasing thermal conductivity, broadening application fields, and improving thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

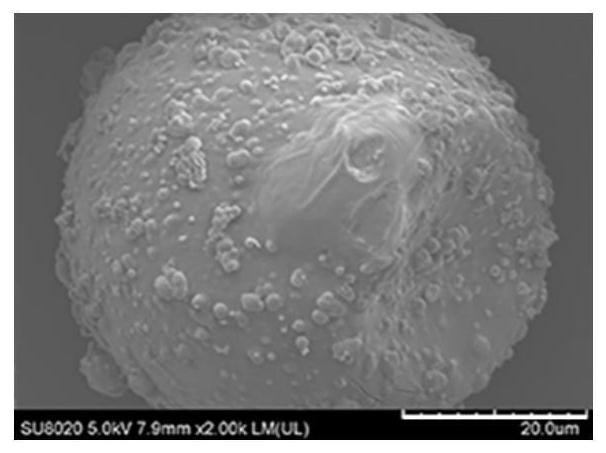

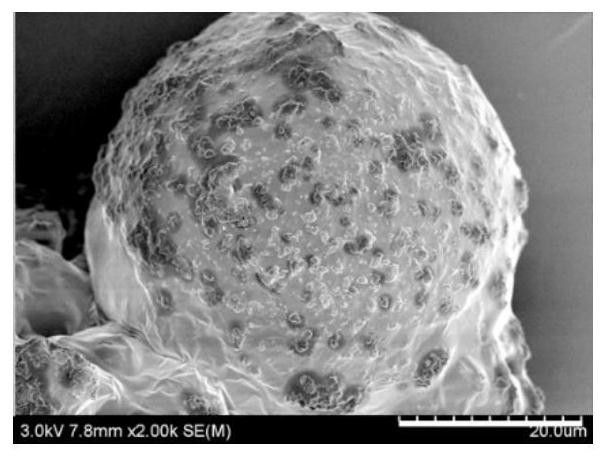

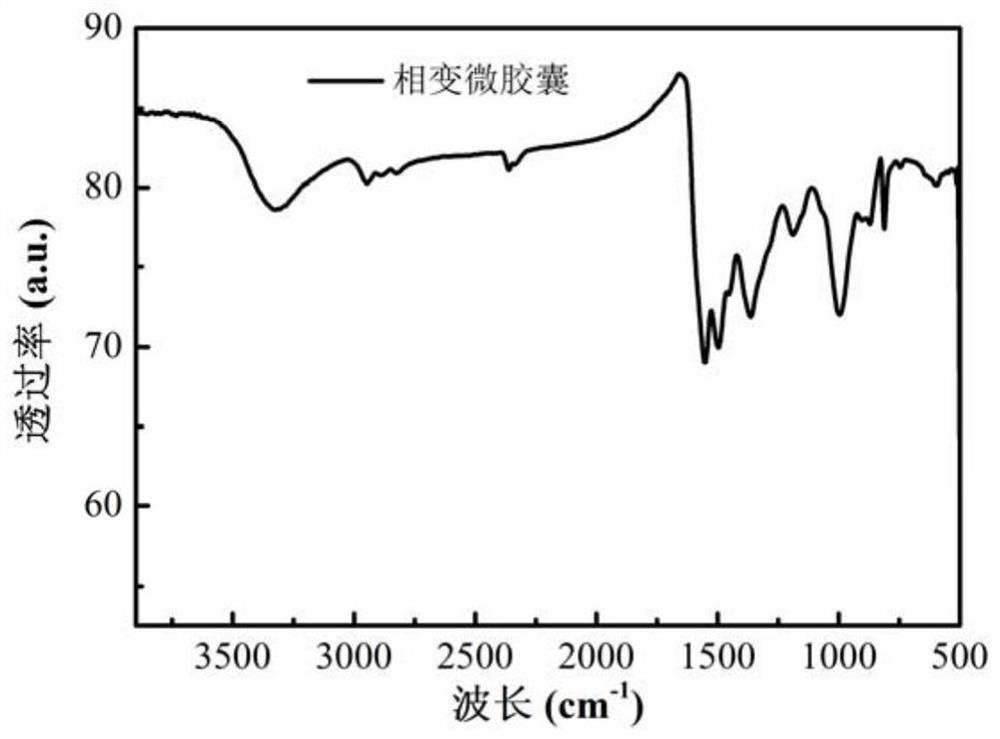

Image

Examples

Embodiment 1

[0039] This embodiment provides a method for preparing magnetic phase-change microcapsules, comprising the following steps:

[0040] 1) Preparation of oil-in-water emulsion: Add 12g of paraffin and 10g of sodium salt of styrene-maleic anhydride copolymer (also known as SMAHNa emulsifier) in 100ml of deionized water successively, melt at a water bath temperature of 70° C. Stir and emulsify at a rotating speed for 2 hours to form a uniformly mixed and stable oil-in-water emulsion; then add citric acid / acetic acid solution with a mass fraction of 10%, adjust the pH value to 4-5, and stir evenly;

[0041] 2) Preparation of prepolymer solution: 0.3g urea, 2.7g melamine, 4.6g formaldehyde, 0.9g nanometer Fe solution were mixed and 25ml deionized water was added, stirred evenly; Ethanolamine solution, adjust the pH value to 8-9, mechanically stir and react in a constant temperature water bath at 70°C and 500rpm for 30min to obtain a prepolymer solution;

[0042] 3) In-situ polymer...

Embodiment 2

[0044]This embodiment provides a method for preparing magnetic phase-change microcapsules, comprising the following steps:

[0045] 1) Preparation of oil-in-water emulsion: sequentially add 12 g of paraffin and 10 g of sodium salt of styrene-maleic anhydride copolymer to 100 ml of deionized water, melt at a water bath temperature of 70° C., stir and emulsify at a speed of 900 rpm for 2 h to make it Form a well-mixed and stable oil-in-water emulsion; then add a citric acid / acetic acid solution with a mass fraction of 10%, adjust the pH value to 4-5, and stir evenly;

[0046] 2) Preparation of prepolymer solution: 6.6g formaldehyde, 3g melamine, 0.8g nano Fe 3 o 4 The solution was mixed and 25ml of deionized water was added, and stirred evenly; then a triethanolamine solution with a mass fraction of 10% was added dropwise to it, the pH value was adjusted to 8-9, and the reaction was mechanically stirred in a constant temperature water bath at 70°C and 500rpm for 30min. Obtain ...

Embodiment 3

[0049] This embodiment provides a method for preparing magnetic phase-change microcapsules, comprising the following steps:

[0050] 1) Preparation of oil-in-water emulsion: sequentially add 12g of n-octadecane and 11g of sodium salt of styrene-maleic anhydride copolymer to 100ml of deionized water, melt at a water bath temperature of 70°C, and stir and emulsify at a speed of 600rpm for 2h to form a uniformly mixed and stable oil-in-water emulsion; then add a citric acid / acetic acid solution with a mass fraction of 10 wt%, adjust the pH value to 4-5, and stir evenly;

[0051] 2) Preparation of prepolymer solution: 7g formaldehyde, 3g melamine, 0.8g nano-CrO 2 The solution was mixed and 25ml of deionized water was added, and stirred evenly; then a triethanolamine solution with a mass fraction of 10% was added dropwise to it, the pH value was adjusted to 8-9, and the reaction was mechanically stirred in a constant temperature water bath at 70°C and 500rpm for 30min. Obtain prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com