Manufacture method of heat-resistant high-performance zipper tooth strip for protective clothing

A high-performance, protective clothing technology, applied in applications, clothing, sliding fastener components, etc., can solve the problems of high temperature resistance, strong protection performance, etc., and achieve the effects of improving aging resistance, preventing filler agglomeration, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

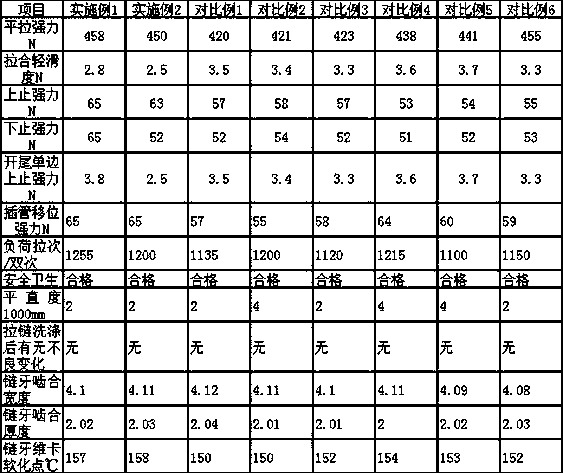

Examples

Embodiment 1

[0022] A method for preparing a heat-resistant high-performance zipper tape for protective clothing, comprising the following steps: (1) Microwave aging treatment: 110 parts of fluorocarbon resin powder, 10 parts of graphite fiber, 11 parts of talcum powder, 12 parts of filler 1 part, 0.4 part of lubricant, 5 parts of potassium titanate whiskers, heated and aged in microwave at 2600MHz at 100°C for 2 hours to obtain mixture A; (2) Add the modifying agent to n-butanol to prepare A solution with a weight concentration of 6%, and then add citric acid to adjust the pH value of the solution to 6.5 to obtain a modified solution; (3) Take the mixture A respectively, and use the ratio of the modified solution and the mixture A to be 0.2:100 according to the mass ratio Add the modified liquid to the mixture A, then add the dispersant of 1% by mass of the mixture A, mix and react at 50~70°C, and the reaction time is 4 hours; (4) Raise the temperature to 100°C , carry out drying treatmen...

Embodiment 2

[0032] A method for preparing a heat-resistant high-performance zipper tape for protective clothing, comprising the following steps: (1) Microwave aging treatment: 100 parts of fluorocarbon resin powder, 5 parts of graphite fiber, 4 parts of talcum powder, 8 parts of filler 1 part, 0.3 part of lubricant, 2 parts of potassium titanate whiskers, heated and aged in microwave at 2450~2600MHz at 80°C for 1 hour to obtain mixture A; (2) Add the modifying agent to n-butanol, Prepare a solution with a weight concentration of 4-6%, and then add citric acid to adjust the pH value of the solution to 5.5 to obtain a modified solution; (3) Take the mixture A respectively, and according to the mass ratio of the modified solution and the mixture A, the mass ratio is 0.2 : The ratio of 100 is to add the modified liquid to the mixture A, then add 0.5% of the mass of the mixture A dispersant, mix and react at 50~70°C, and the reaction time is 1 hour; (4) Raise the temperature The temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com