A vehicle shock-absorbing buffer seat based on a four-link adjustment mechanism

An adjustment mechanism and four-link technology, applied in vehicle seats, vehicle parts, movable seats, etc., can solve the problems of reduced fatigue and work efficiency, large adjustment steps of the height adjustment mechanism, and no large impact cushioning function of the seat. Achieve the effect of reducing vibration and improving vibration comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

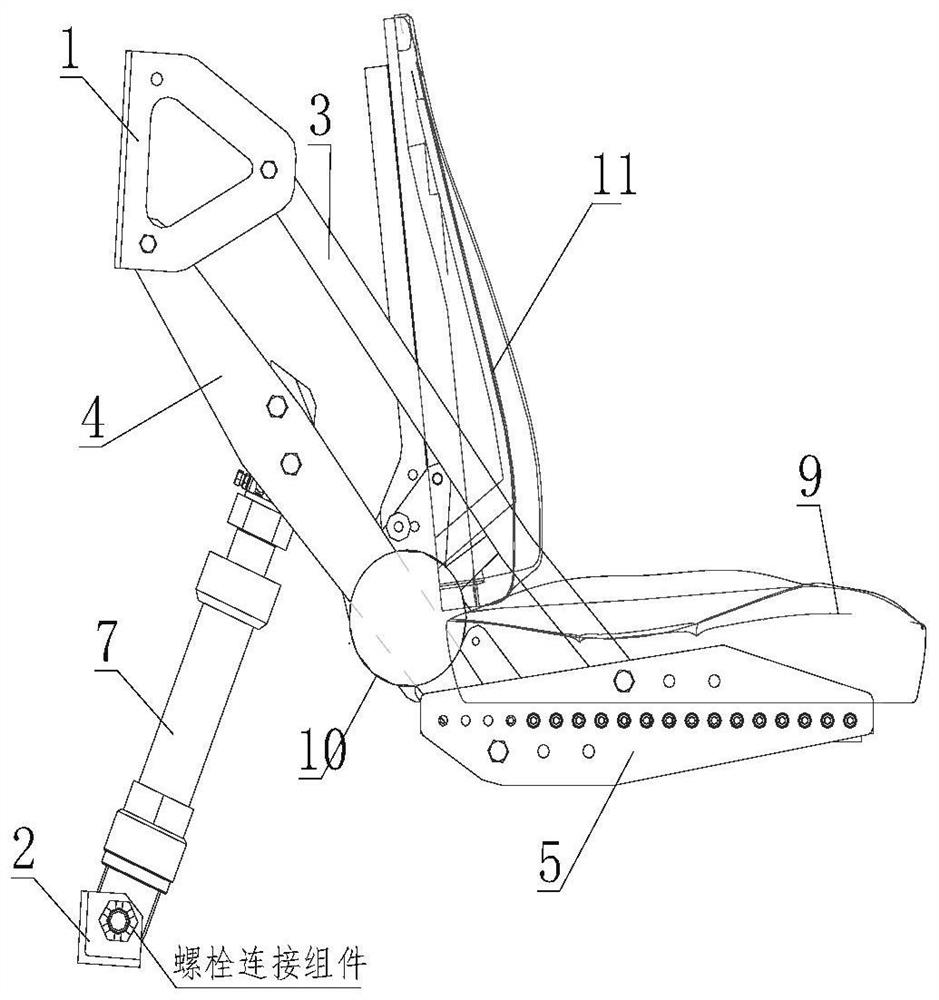

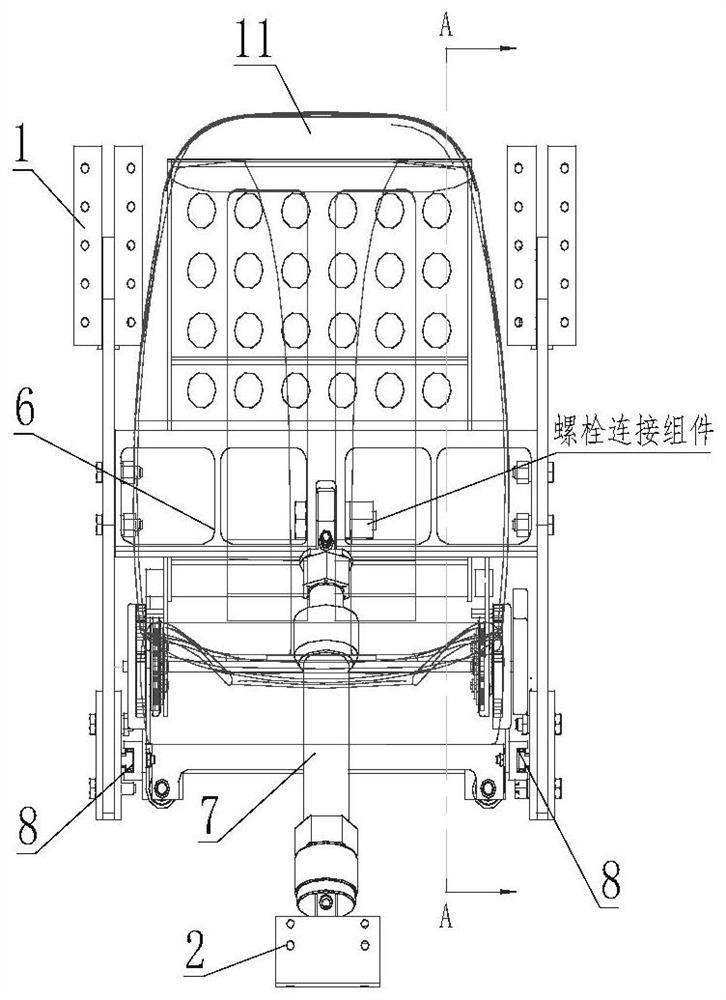

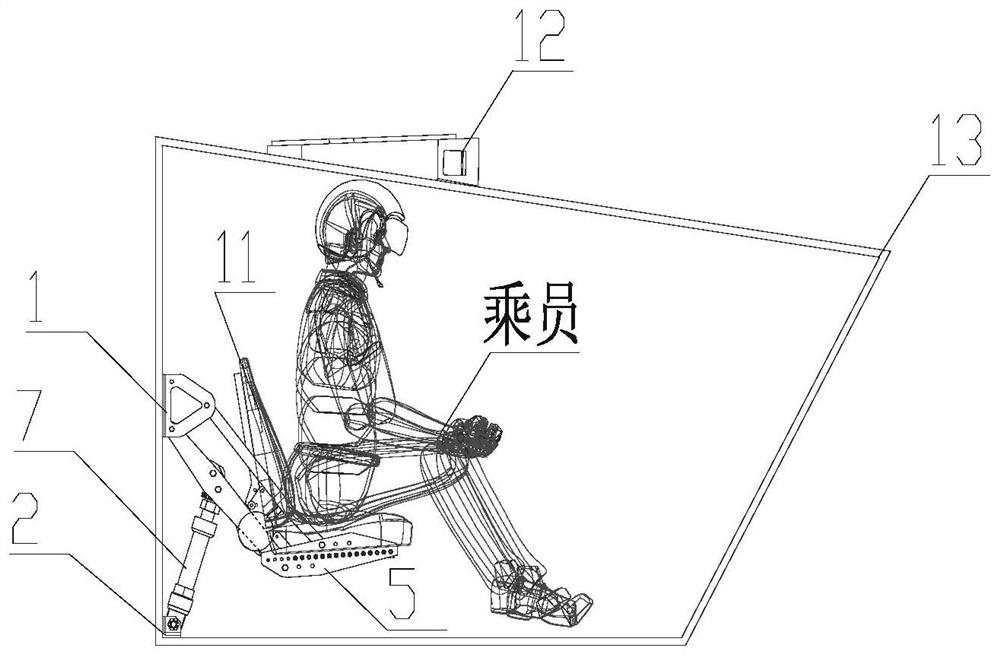

[0020] as attached figure 1 As shown, the present invention provides a vehicle vibration-damping buffer seat based on a four-bar linkage adjustment mechanism. The seat in the vibration-damping buffer seat is installed on the seat installation side plate 5 through a slide rail assembly 8, and the seat The chair installation side plate 5 is installed on a four-link adjustment mechanism with a wide range of seat height adjustment functions. The seat is composed of three parts: seat cushion assembly 9, recliner 10 and backrest assembly 11.

[0021] like figure 1 , figure 2 , image 3 As shown, there is an upper fixed seat 1, an upper link 3, a lower link 4 and a seat installation side plate 5 on the left and right sides of the seat, and the fixed seat 1 on each side of the seat is fixed by bolts or welding. On the vehicle body 13, the upper end of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com