V-process production line

A production line and cable technology, which is applied to the parts of molding machines, casting molding equipment, casting molds, etc., can solve the problems of time-consuming and labor-intensive work efficiency, and achieve the effects of stable transfer and transportation, prevention of lateral deviation, and time-saving and labor-saving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

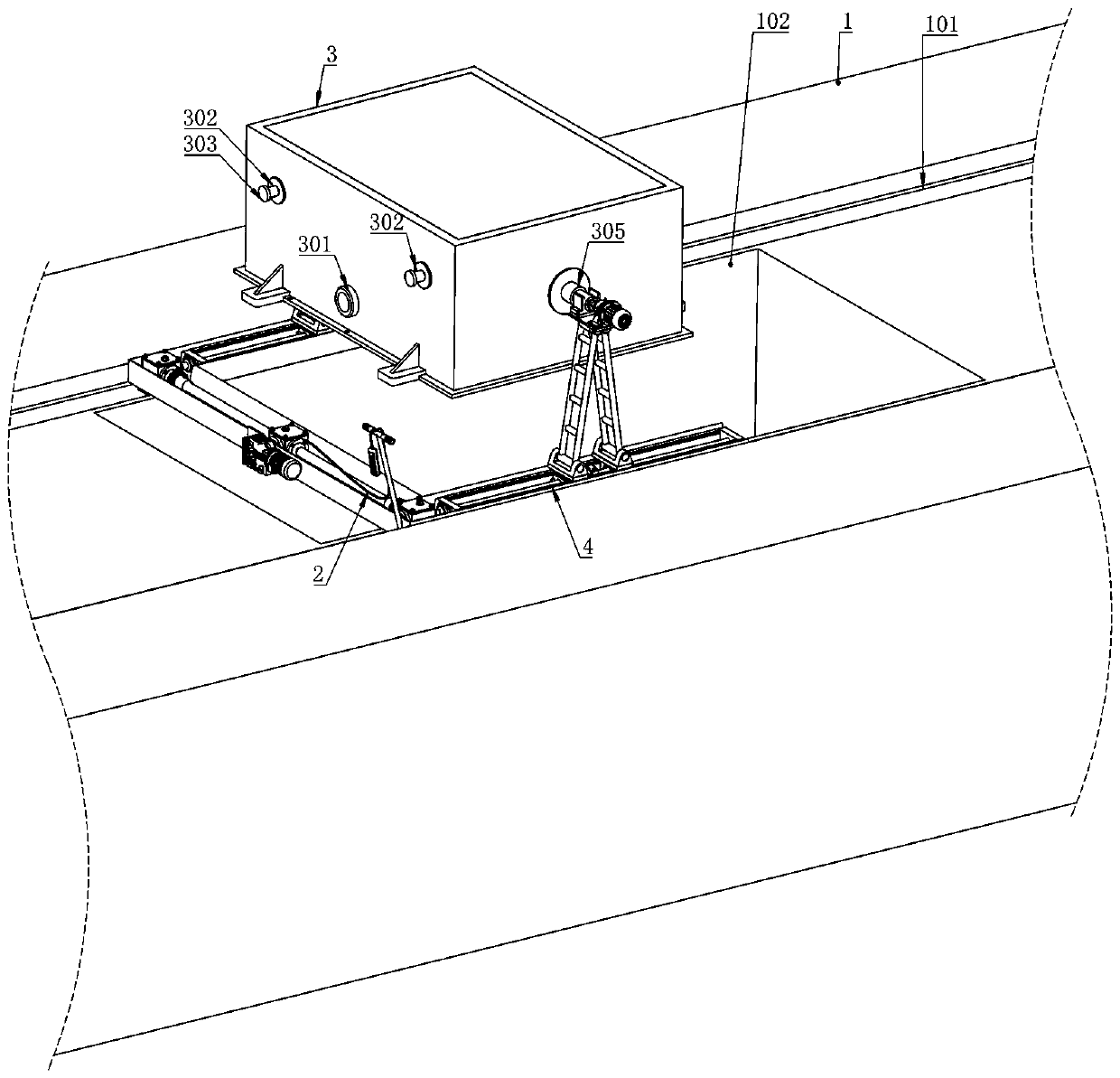

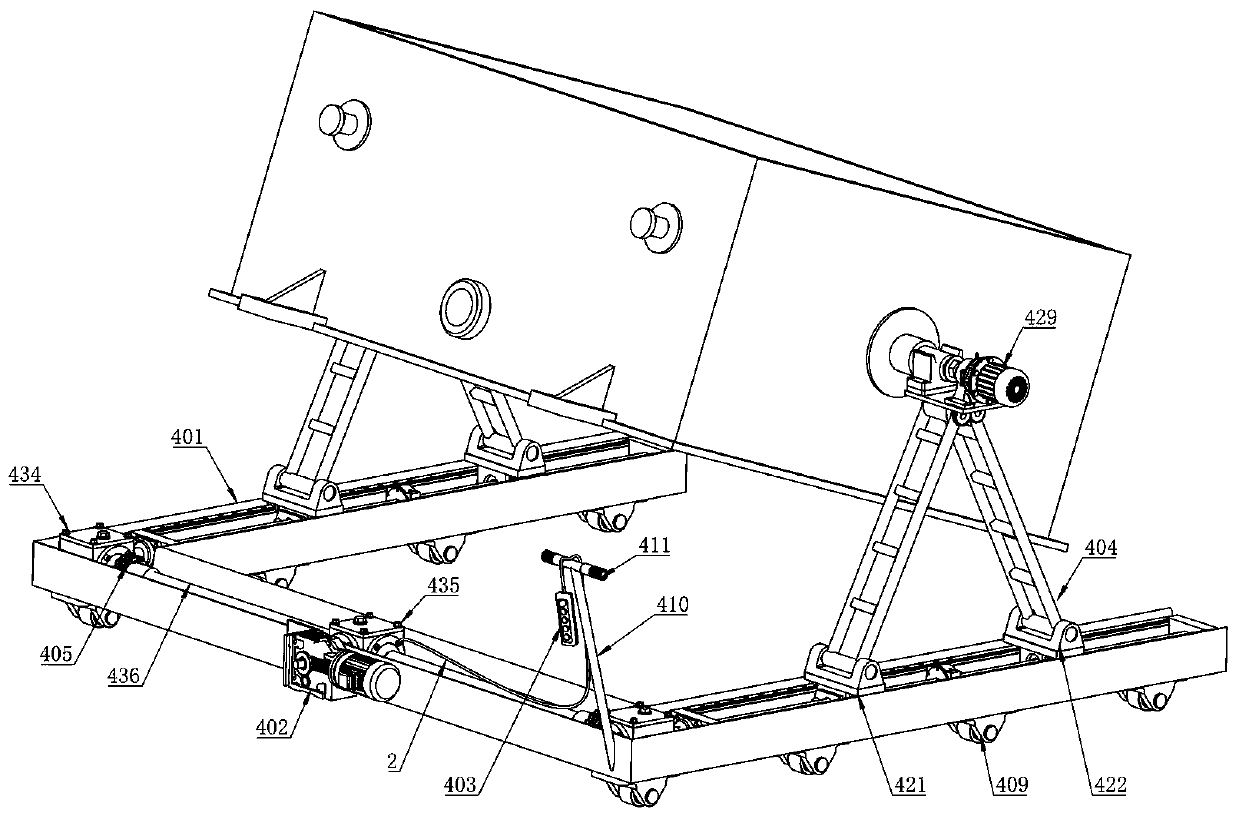

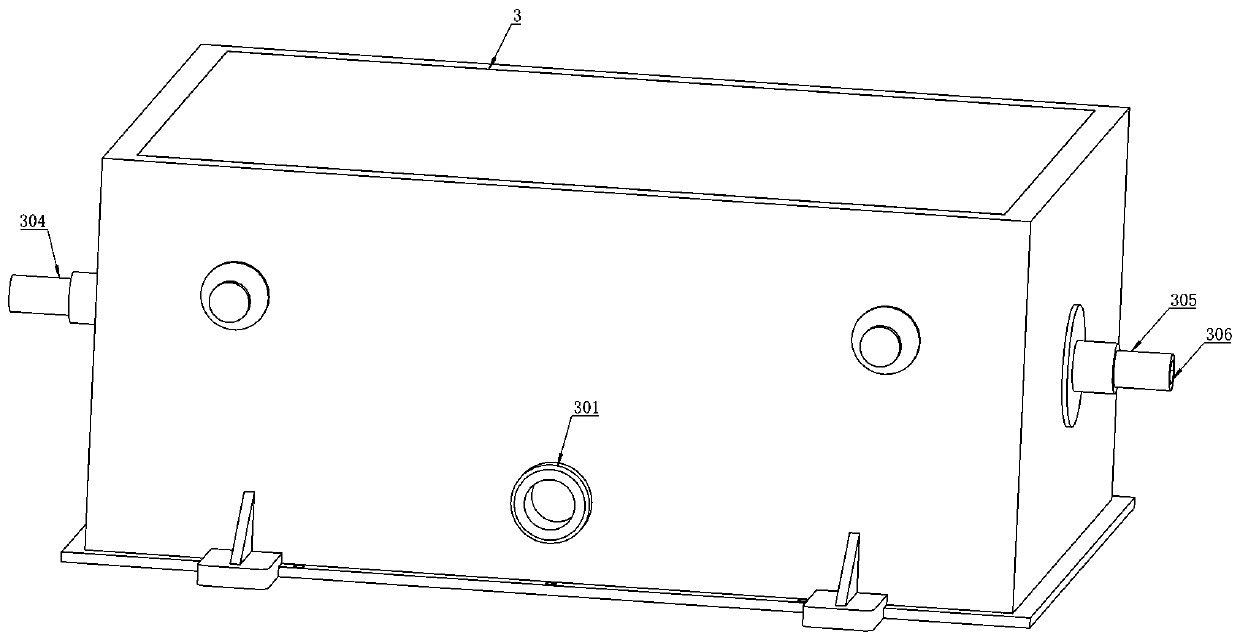

[0035] Specific implementation mode one: combine Figure 1-9As shown, a V-method molding production line is characterized in that: it includes a cement surface 1, a cable 2, a mold box 3 and a fast-moving demoulding device 4; a casting port 301 is provided through the lower part of the front side of the mold box 3; A lifting column 302 is fixedly arranged above the middle of the front and rear sides of the mold box 3; a stopper 303 is provided at one end of the lifting column 302; a slide rail 101 is provided at the middle of the cement surface 1 in the length direction; the fast moving The demoulding device 4 is arranged inside the slide rail 101; the middle part of the cement surface 1 is provided with a mold groove 102 between the slide rails 101; the fast moving demoulding device 4 includes a track base 401, a lifting motor 402, Control handle switch 403, lifting frame 404, coupling 405, transmission key block 406 and support 425; both sides of the track base 401 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com