Ultrasonic cleaning device

A cleaning device and ultrasonic technology, applied in transportation and packaging, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of low production efficiency, large manpower and material resources, and many transfers between processes, and achieve simple operation and transfer. The effect of stable process and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

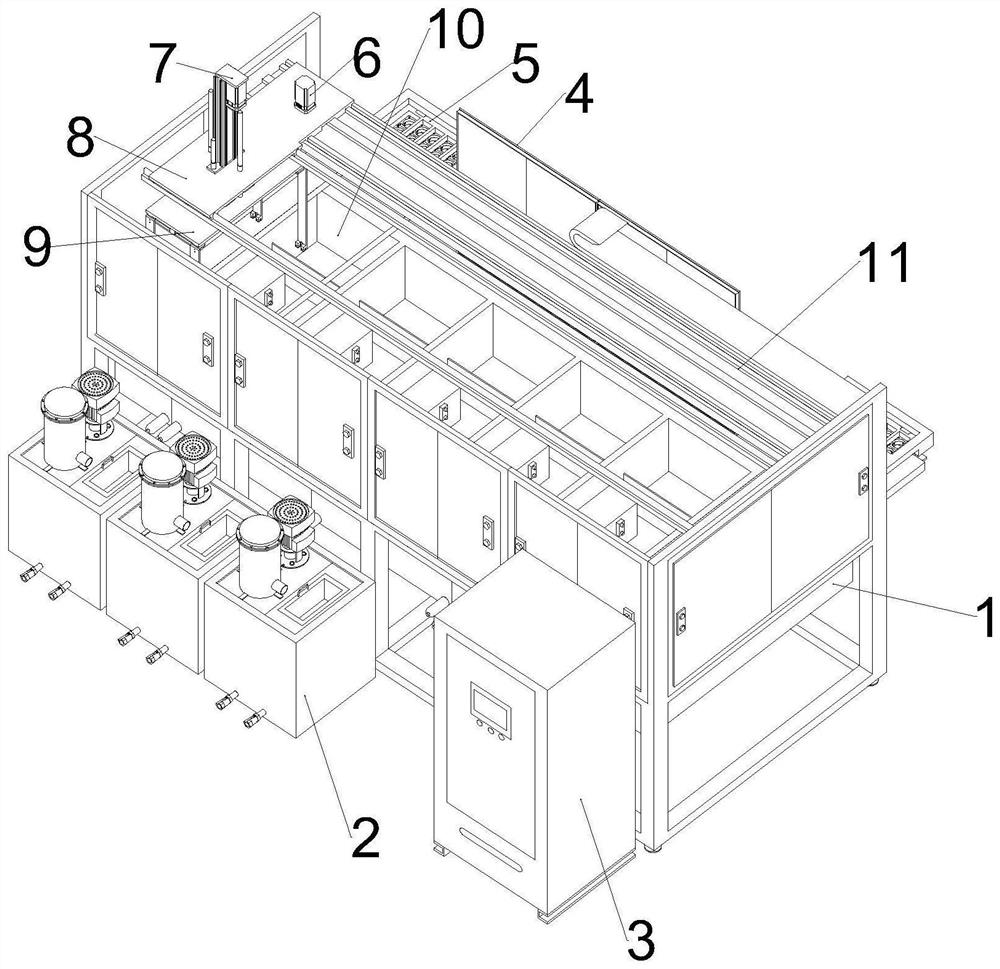

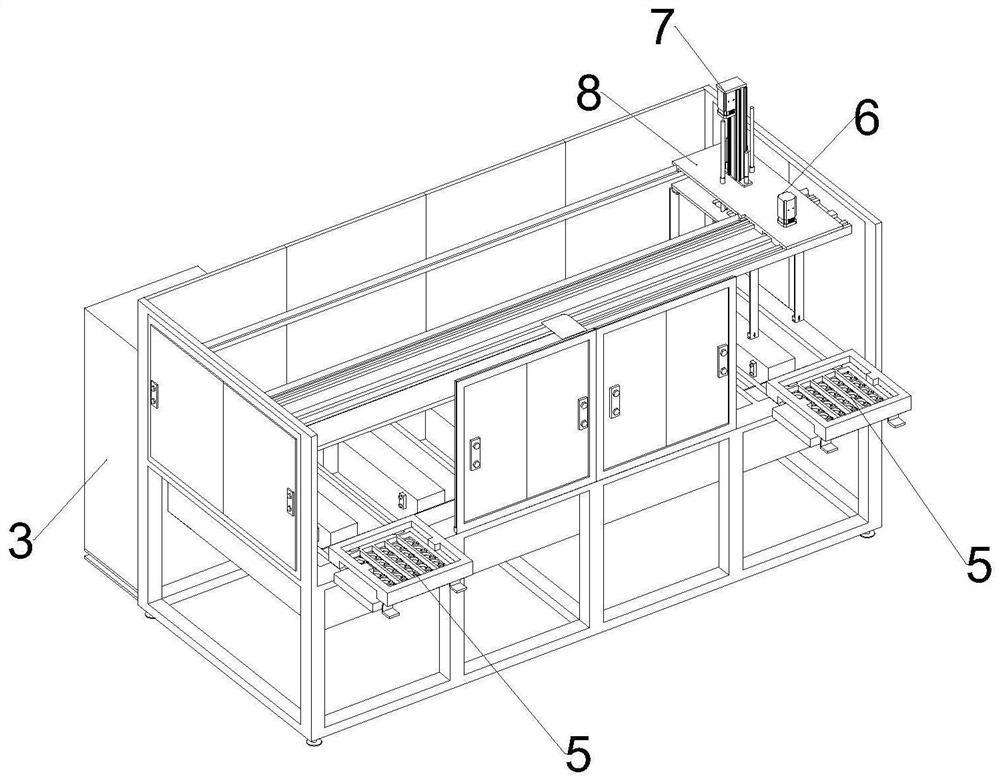

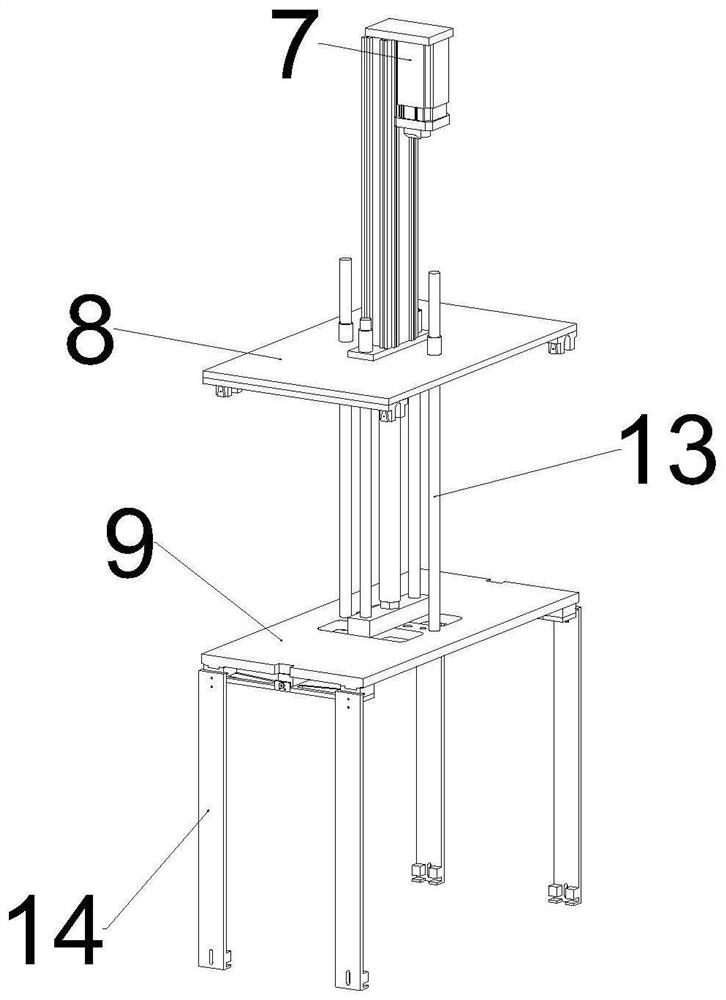

[0031] Example 1: Ultrasonic cleaning device

[0032] As attached to the manual Figure 1-10 shown. An ultrasonic cleaning device provided by the present invention includes a frame body 1, an ultrasonic generating mechanism, a control box 3, a filtration circulation structure 2 and a liquid tank 10, the ultrasonic generating structure is arranged under the liquid tank 10, and the upper part of the frame body 1 is provided with The gantry translational sliding table mechanism, the gantry translational sliding table mechanism is equipped with manipulator jaws 14, the middle part of the frame body 1 is provided with a liquid tank 10, the liquid tank 10 has several cavities spliced together, and the liquid tank 10 is equipped with loading and unloading on both sides. Position 5, the control box 3 is electrically connected with the ultrasonic generating structure, the gantry translation slide mechanism, the gripper jaw 14 of the manipulator and the filtering circulation structur...

Embodiment 2

[0040] Embodiment 2: Application of ultrasonic cleaning device

[0041] During use, the operator or manipulator places the products to be cleaned in the tray 18. For small devices, a tray structure formed by clamping multiple sets of tooling can be used, and each product is individually stuck in a tooling. After the tray is installed, clip the tray onto the tray clamping tool 19, use the claw positioning groove on the back of the pallet clamping tool 19 to grab and move, put the tray 18 and the pallet clamping tool 19 together on the upper and lower material positions In the positioning tool on the translational slide rail, the translational slide rail sends it under the jaws of the manipulator, and the jaw connecting block 15 is driven by the jaw cylinder to move in opposite directions, and the pallet clamping tooling 19 is clamped. After being lifted by the servo motor 7, The drive motor 6 drives the gantry translation slide mechanism to move to the liquid tank 10, lowers th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com