Preparation method and application of BiOCl/carbonized egg membrane composite visible light catalyst

A technology of egg membrane and visible light, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and water treatment of special compounds, can solve the problems of high cost and complicated preparation process, and achieve the promotion of promotion, promotion of catalytic activity, and reduction of waste Effects of waste disposal and environmental pollution pressures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

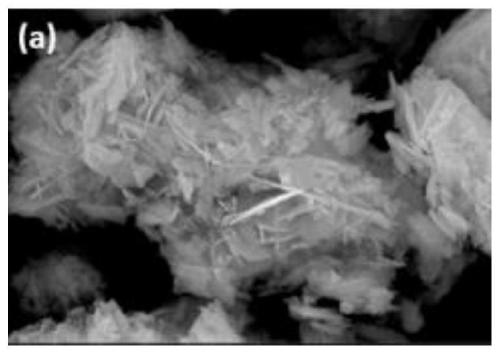

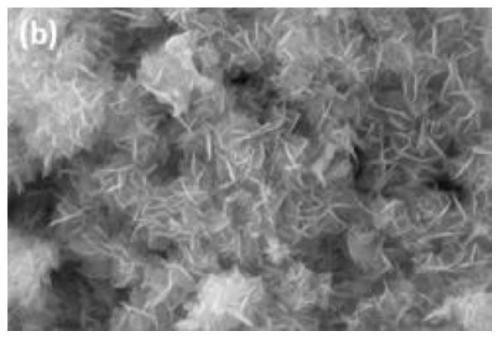

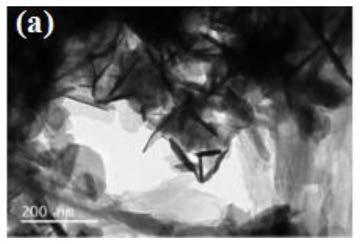

[0037]Preparation of Carbon Quantum Dots Modified BiOCl / Carbonized Egg Membrane Composite Visible Light Catalyst:

[0038] Collect discarded egg shells, wash the egg shells with clean water, and then soak the washed egg shells in dilute hydrochloric acid, where the concentration of dilute hydrochloric acid is 0.5mol / L. Rinse well, dry at 60°C and cut into pieces with scissors to obtain egg membrane fragments; put the obtained egg membrane fragments into a muffle furnace for calcination under a nitrogen atmosphere, heat at a heating rate of 5°C / min to 550°C for 2 hours, A black solid can be obtained, which can be ground into particles to obtain carbonized egg membrane, which is recorded as: CESM.

[0039] To 1.86g Bi(NO 3 ) 3 Add 25 mL of hydrochloric acid with a concentration of 2 mol / L, 20 mL of deionized water and 10 mL of ethanol to the solid, then add 0.05 g of carbonized egg membrane, ultrasonicate for 30 min, add 20 mL of NaOH solution with a concentration of 4 mol / L d...

Embodiment 2

[0042] Preparation of BiOCl photocatalyst modified by eggshell waste:

[0043] Collect discarded egg shells, wash the egg shells with clean water, and then soak the cleaned egg shells in dilute hydrochloric acid, wherein the concentration of dilute hydrochloric acid is 0.5mol / L. Rinse well, dry at 60°C and cut into pieces with scissors to obtain egg membrane fragments; put the obtained egg membrane fragments into a muffle furnace for calcination under a nitrogen atmosphere, heat at a heating rate of 5°C / min to 550°C for 2 hours, A black solid can be obtained, which is ground into particles to obtain carbonized egg membrane, which is recorded as CESM;

[0044] To 1.86g Bi(NO 3 ) 3 Add 25mL of hydrochloric acid solution with a concentration of 2mol / L, 20mL of deionized water and 10mL of ethanol to the solid, then add 0.01g of carbonized egg membrane, ultrasonicate for 30min, and add 20mL of NaOH solution with a concentration of 4mol / L during continuous stirring for 30min. Fin...

Embodiment 3

[0046] Preparation of BiOCl photocatalyst modified by eggshell waste:

[0047] Collect discarded egg shells, wash the egg shells with clean water, and then soak the cleaned egg shells in dilute hydrochloric acid, wherein the concentration of dilute hydrochloric acid is 0.5mol / L. Rinse well, dry at 60°C and cut into pieces with scissors to obtain egg membrane fragments; put the obtained egg membrane fragments into a muffle furnace for calcination under a nitrogen atmosphere, heat at a heating rate of 5°C / min to 550°C for 2 hours, A black solid can be obtained, which is ground into particles to obtain carbonized egg membrane, which is recorded as CESM;

[0048] To 1.86g Bi(NO 3 ) 3 Add 25mL of hydrochloric acid solution with a concentration of 2mol / L, 20mL of deionized water and 10mL of ethanol to the solid, and then add 0.1g of carbonized egg membrane, sonicate for 30min, and add 20mL of NaOH solution with a concentration of 4mol / L during continuous stirring for 30min. Final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com