Environment-friendly edible tubular product and preparation method thereof

A tubular, environmentally friendly technology, applied in food forming, application, table utensils and other directions, can solve problems such as harming health, softening and breaking, polluting the environment, etc., and achieves the effect of reducing white pollution, low production cost, and no toxic side effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043]The present invention also provides a method for preparing the above-mentioned environmentally friendly edible tubular product, comprising the following steps:

[0044] S1, ingredients: add prolamin to the solvent, fully dissolve, add main powder, thickening powder, water and mix evenly to obtain a mixture. Preferably, the main powder and the thickening powder are pre-mixed evenly and then sieved, then added to the prolamin solution and mixed evenly.

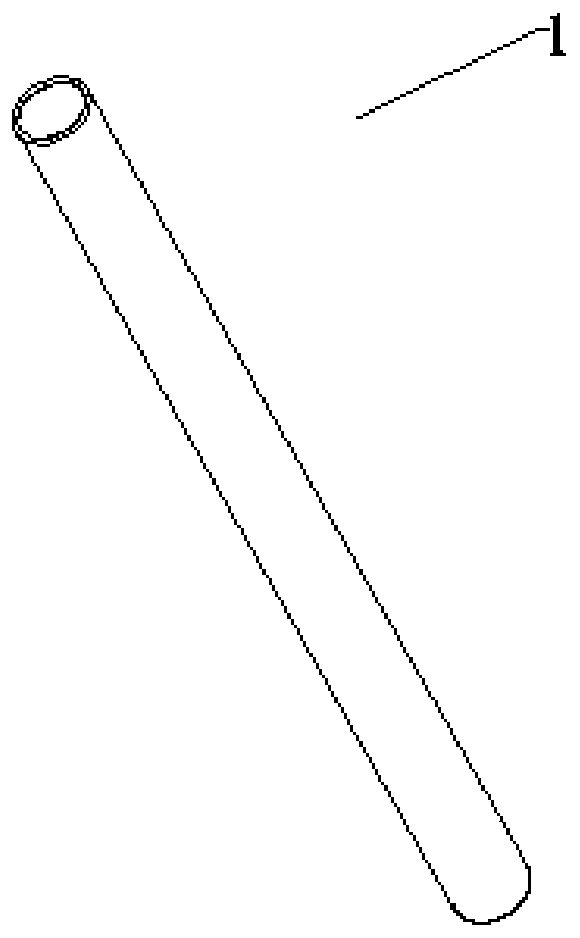

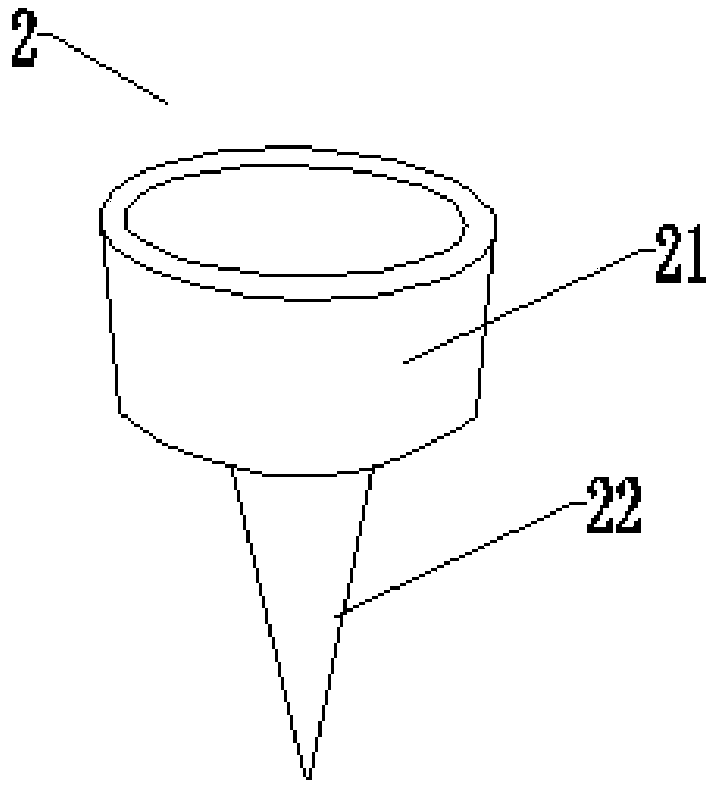

[0045] S2, Molding: Install the molding die and cutting knife of the molding machine according to the diameter and length requirements of the product, pour the mixture into the molding machine for extrusion molding, and obtain a molded product. Wherein, the inner cavity diameter of the forming mold is 1-20mm. During the preparation process, it is replaced according to the diameter and length requirements of the product.

[0046] S3, air-drying: air-dry the molded article at a temperature of 5-70° C. for 5-20 minutes. Th...

Embodiment 1

[0059] An environmentally friendly edible straw provided in this embodiment is prepared by the following steps:

[0060] S1, ingredients: add 3 parts of zein to 10 parts of 90% ethanol, after fully dissolved, add 50 parts of rice flour, 15 parts of yam powder, 5 parts of edible gelatin, 2 parts of purple sweet potato powder, 15 parts of water and mix well , to get a mixture;

[0061] S2, molding: adjust the extrusion diameter of the molding machine to 10mm, pour the mixture into the molding machine and extrude to obtain a molded product;

[0062] S3, air-drying: air-dry at 30°C for 15 minutes;

[0063] S4, cutting: cutting the molded product into a predetermined length;

[0064] S5, drying: drying the molded product at a temperature of 50°C for 10 minutes, then continuously raising the temperature for 10 minutes to 80°C, and keeping it for 10 minutes, and finally continuing to heat it for 10 minutes to 100°C, and keeping it for 10 minutes;

[0065] S6, cooling at 25° C. for...

Embodiment 2

[0067] An environmentally friendly edible straw provided in this embodiment is prepared by the following steps:

[0068] S1, ingredients: add 3 parts of zein to 10 parts of 90% ethanol, after fully dissolved, add 50 parts of sorghum flour, 15 parts of yam powder, 5 parts of edible gelatin, 2 parts of purple sweet potato powder, 15 parts of water and mix well , to get a mixture;

[0069] S2, molding: adjust the extrusion diameter of the molding machine to 10mm, pour the mixture into the molding machine and extrude to obtain a molded product;

[0070] S3, air-drying: air-dry at 30°C for 15 minutes;

[0071] S4, cutting: cutting the molded product into a predetermined length;

[0072] S5, drying: drying the molded product at a temperature of 50°C for 10 minutes, then continuously raising the temperature for 10 minutes to 80°C, and keeping it for 10 minutes, and finally continuing to heat it for 10 minutes to 100°C, and keeping it for 10 minutes;

[0073] S6, cooling at 25° C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lumen diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com