Cold roller and cold rolling method

A cold rolling mill and stand technology, which is applied in the field of tandem cold rolling mills, can solve the problems of improved rollability, no help, and increased heat loss at the edge of the steel plate, and can prevent the rise of the main unit of rolling oil, The effect of reducing heat loss and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

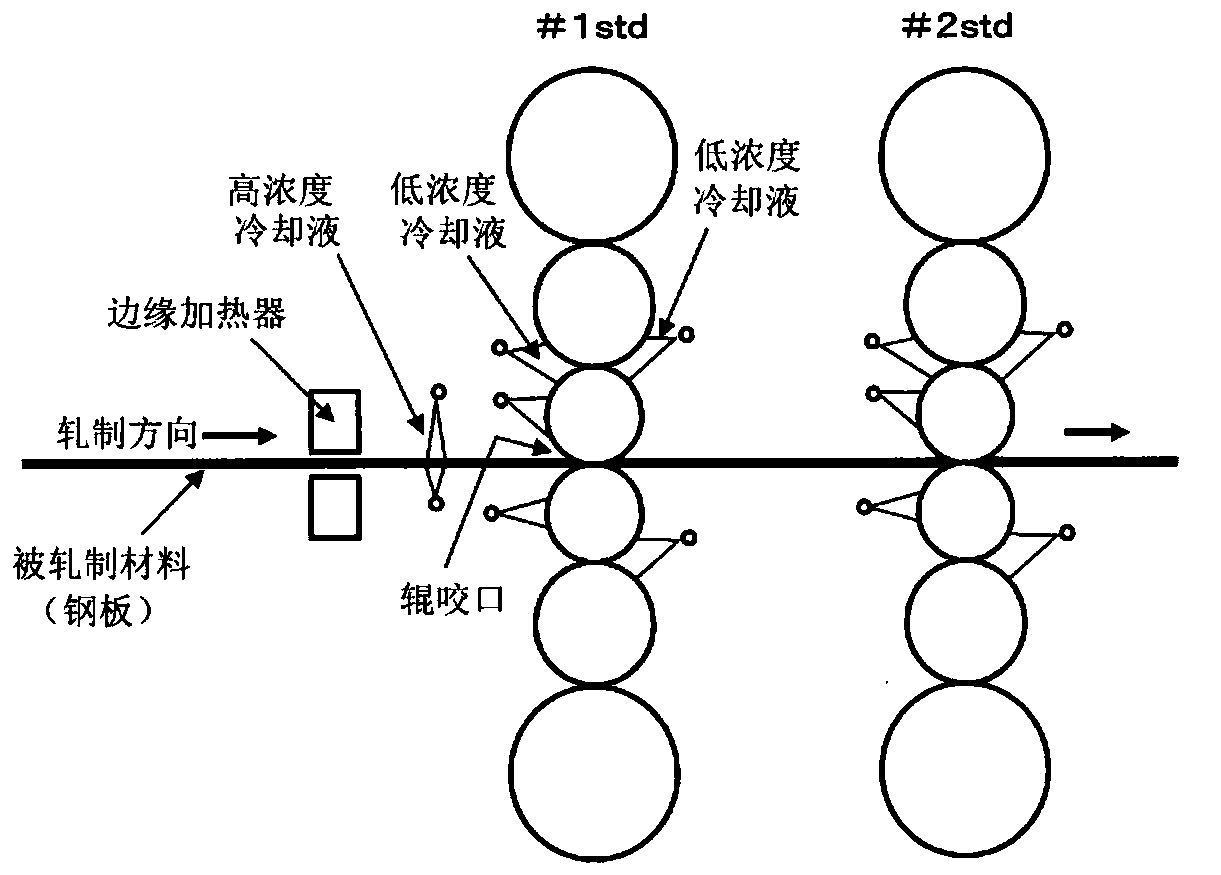

[0053] Such as image 3 As shown, an edge heater of an induction heating method for heating the two edges of the steel plate is used at a position 5 m upstream of the first frame, and a high-concentration coolant sprayer is arranged between the edge heater and the first frame. In a completely continuous tandem cold rolling mill with a high-concentration coolant injection device, experiments were conducted to cold-roll hot-rolled steel sheets with a thickness of 2.0 to 3.0 mm containing 3.0% by mass or more of Si to a thickness of 0.3 to 0.5 mm. .

[0054] Here, since the above-mentioned tandem cold rolling mill is a circulating oil supply system, it is equipped with a low-concentration cooling liquid emulsified by mixing rolling oil containing esters as a main component in water at a concentration of 3% by mass. (Temperature: 50°C), the structure of the low-concentration coolant spraying device sprayed on the outer peripheral surface of the work roll of each stand and between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com