Continuous hydrophobic treatment equipment and method for gas diffusion layer of fuel cell

A technology of gas diffusion layer and hydrophobic treatment, which is applied in the direction of fuel cells, electrical components, battery electrodes, etc., can solve the problems of inability to realize continuous production, achieve continuous automatic operation, ensure consistency, and improve the ability of mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

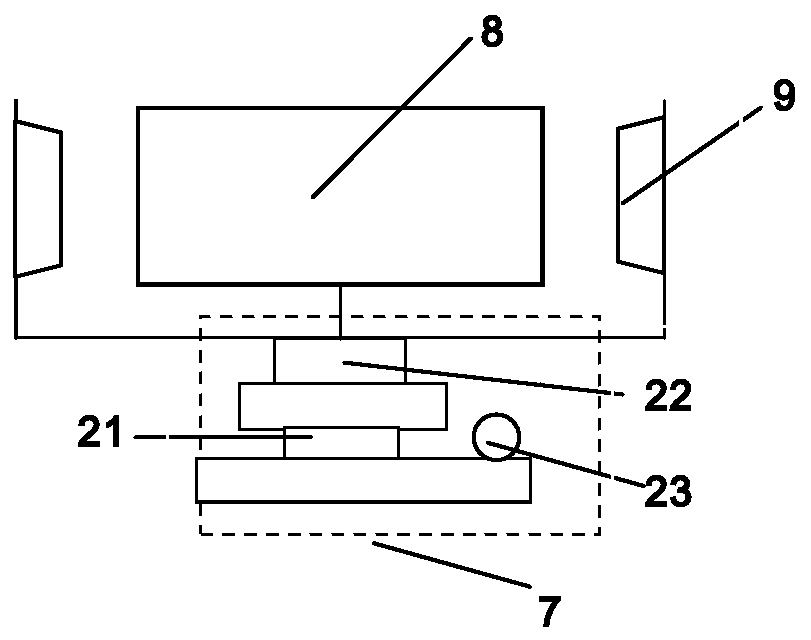

[0035] Such as figure 1 As shown, the present invention provides a fuel cell gas diffusion layer continuous hydrophobic treatment equipment, including: a removal mechanism for transferring the gas diffusion layer 1 to be treated to the dipping-draining-sending mechanism; the dipping-draining dry-sending mechanism, used to impregnate, drain and transfer the gas diffusion layer 1 to a drying mechanism; the drying mechanism is used to dry the gas diffusion layer 1; the receiving mechanism , for collecting the dried gas diffusion layer 1 .

[0036] Further, the removal mechanism includes a servo jacking mechanism I2, an upper material bin 3 and a movable mechanical arm I4; the upper material bin 3 is provided with a support frame I6 for placing the gas diffusion layer 1; The servo jacking mechanism I2 is located below the support frame I6, and is used to drive the support frame I6 to move up and down in the 3 parts of the upper bin; the movable mechanical arm I4 is located above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com